ink scraping device for a printer

A technology of printer and scraper, applied in printing and other directions, can solve the problems of complicated structure, increased cost and position deviation of the scraping device, and achieve the effect of simple and reliable control principle, improving production efficiency and ensuring accurate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

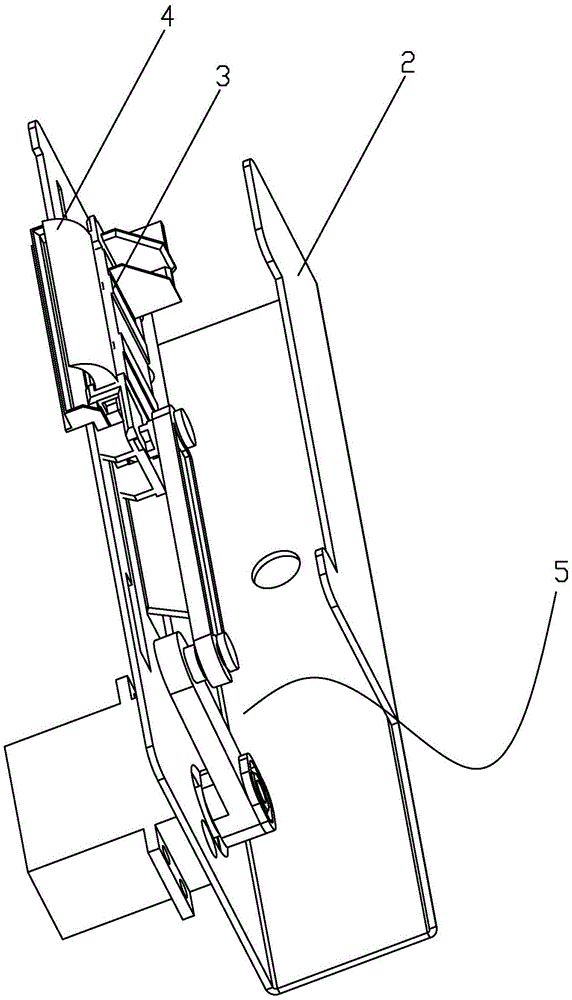

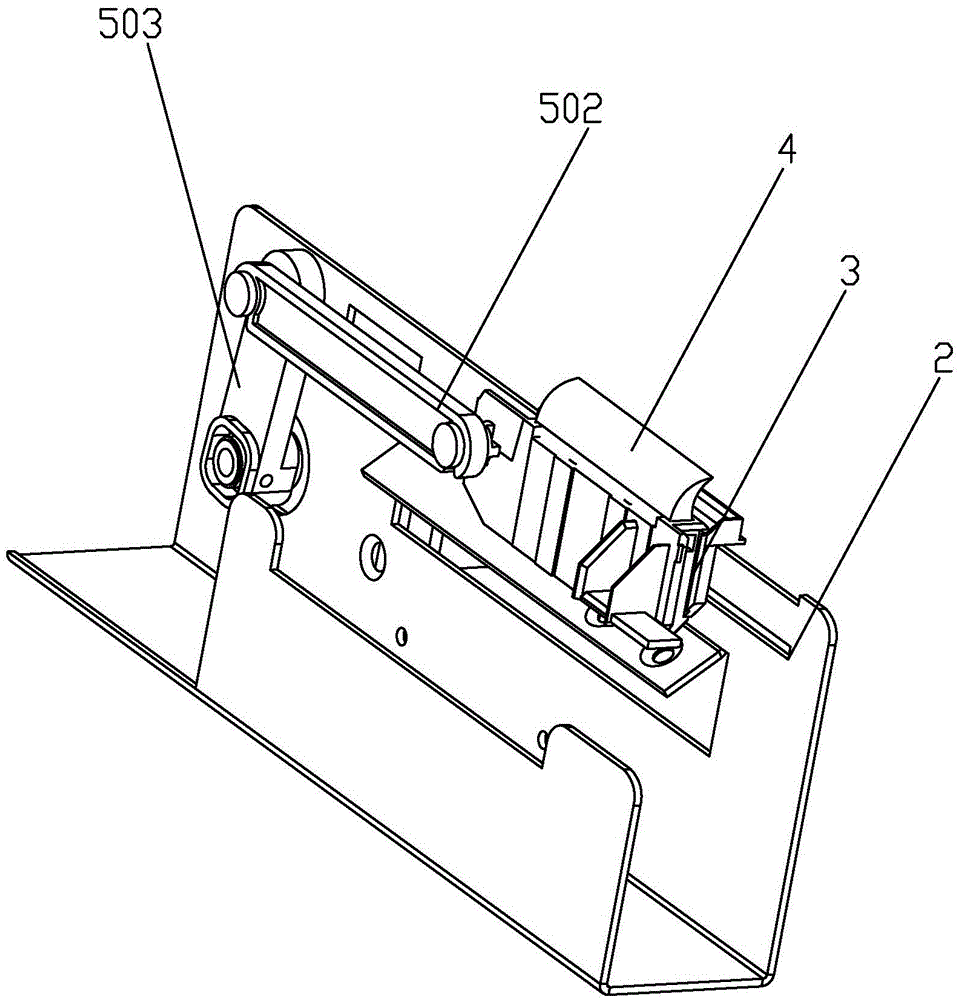

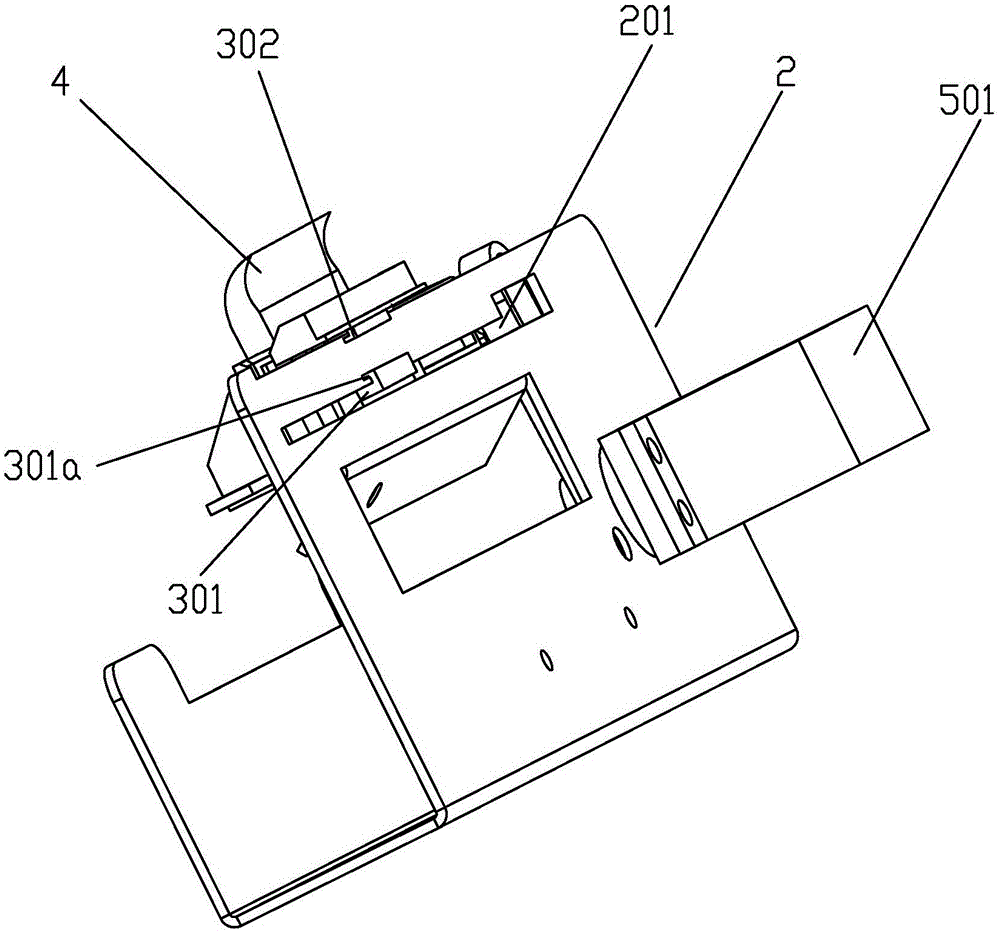

[0024] like Figure 1 to Figure 6 As shown, a ink scraping device of a printer includes a bracket 2 fixedly connected to the frame 1 of the printer, the bracket 2 is provided with a scraper seat 3, and the scraper seat 3 is provided with a scraper 4. The bracket 2 is also provided with a drive mechanism 5 that drives the scraper seat 3 to slide back and forth on the bracket 2, and the drive mechanism 5 includes a The steering gear 501 and the crank 503 fixedly connected with the output shaft of the steering gear 501, the other end of the crank 503 is hinged with a connecting rod 502, the other end of the connecting rod 502 is connected to the scraper seat 3 hinged. The control signal of the steering gear 501 is a pulse signal with a period of about 20 milliseconds and a width of 1 millisecond to 2 milliseconds. When the steering gear 501 receives the signal, it will imme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com