Formation method of semiconductor structure

A semiconductor and isolation structure technology, applied in the field of semiconductor structure formation, can solve the problems of poor stability and reliability, poor performance of flash memory, etc., and achieve the effect of good shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] As mentioned in the background art, even if the conductive structure on the surface of the source region or the drain region is fabricated by a self-aligned electrical contact process, the formed flash memory still has poor performance, poor stability and reliability.

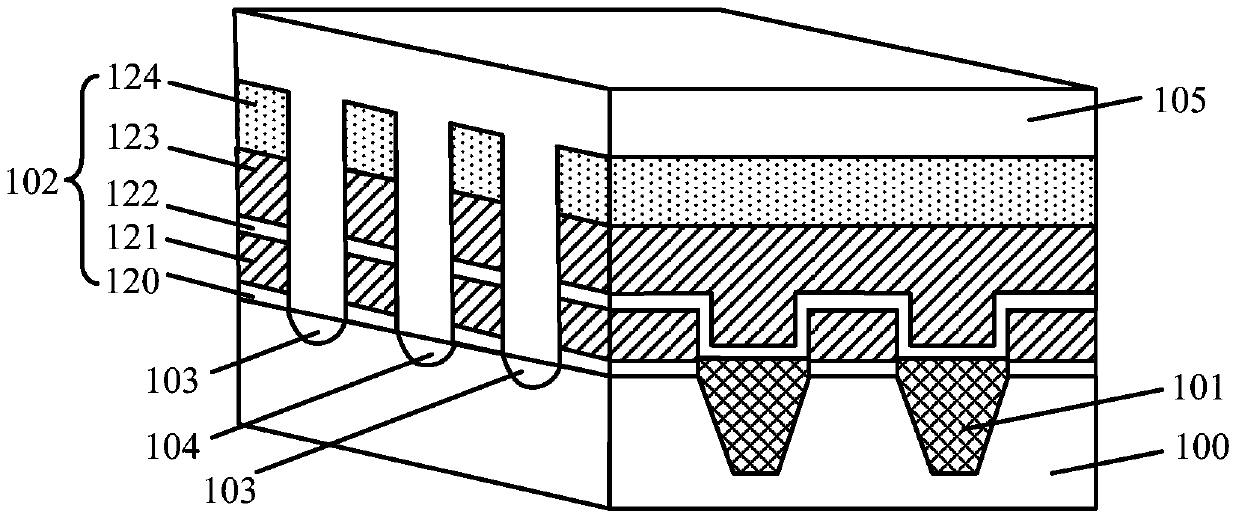

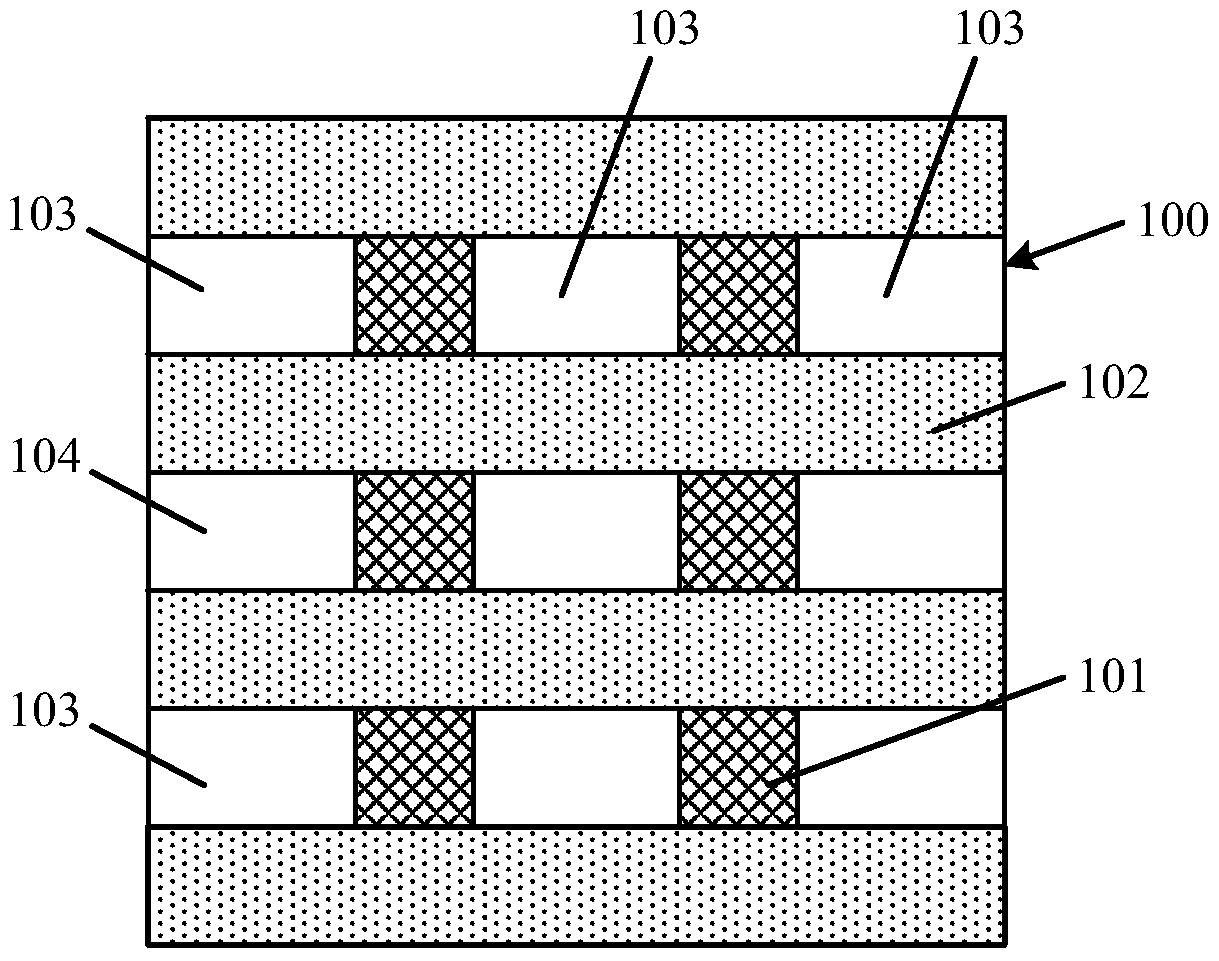

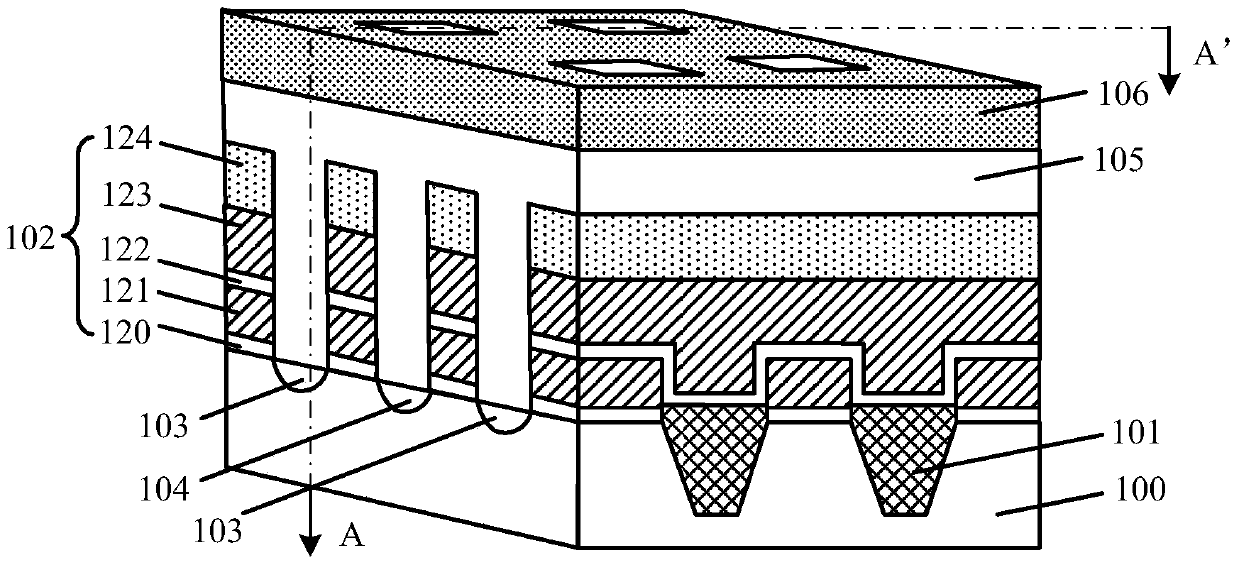

[0034] Figure 1 to Figure 5 It is a schematic cross-sectional structure diagram of a forming process of a memory according to an embodiment of the present invention.

[0035] Please refer to figure 1 and figure 2 , figure 2 yes figure 1 A schematic diagram of a top view structure, a substrate 100 is provided, and the substrate 100 has several active regions, an isolation structure 101 is provided between adjacent active regions, and a gate structure 102 is provided on the substrate surface of part of the active regions. On both sides of the gate structure 102, there are respectively exposed source region trenches and drain region trenches on the surface of the substrate 100 in the active region and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com