Bus insulating bracket with self-repair function

An insulating support and self-repairing technology, which is applied in the direction of fully enclosed busbar devices, can solve the problems of weakened isolation and positioning functions, busbar distance deviation, electrical fires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

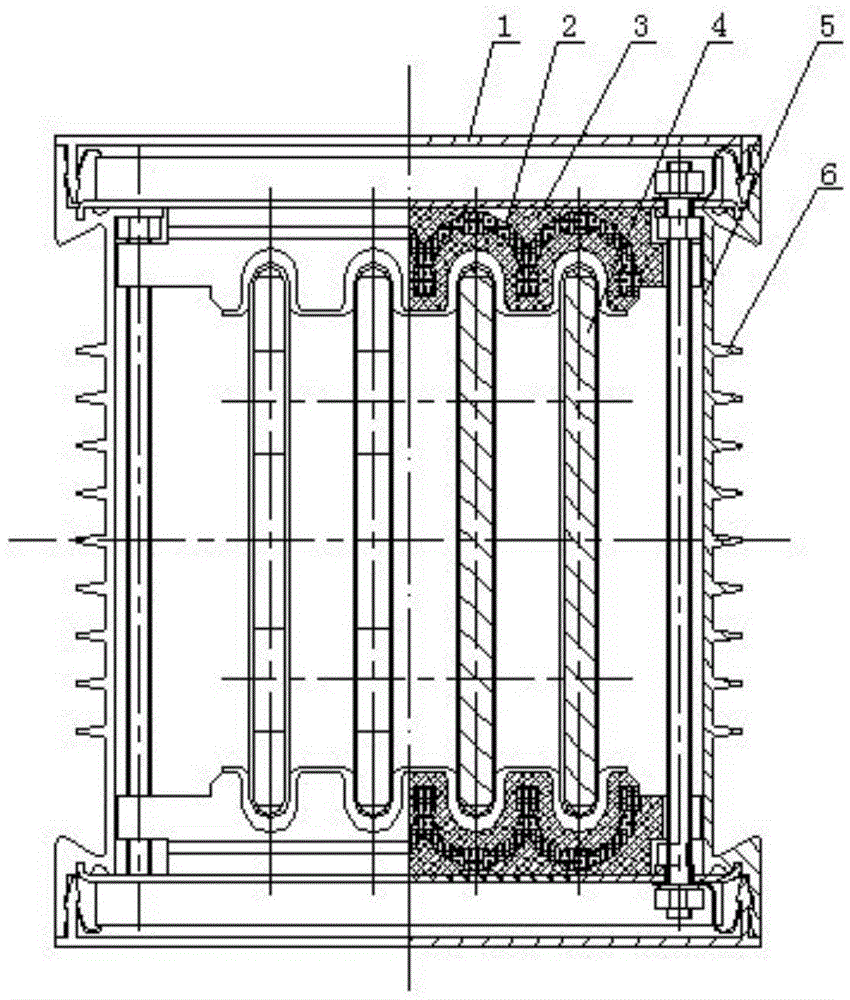

[0012] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

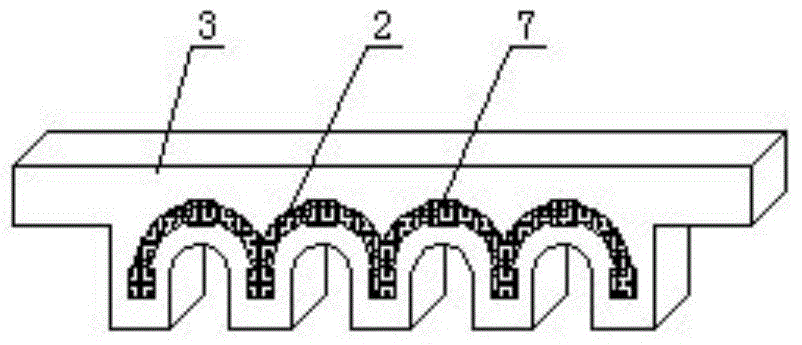

[0013] A busbar insulating support with self-repairing function, the insulating support 3 is installed on the upper and lower ends of the busbar 4 of the busbar groove, the busbar groove is composed of a top plate 1, a side plate 5 and a busbar, and the side plate is made There are cooling fins 6.

[0014] The insulating bracket is a composite insulating bracket, and a rubber spring 2 is embedded in the insulating bracket. The rubber spring is formed with a reinforcing block 7 at the stress-bearing part of the busbar. Top and sides. . The insulating bracket can be deformed and self-repairing through the rubber spring, and the reinforcing block made of the rubber spring can increase the elastic deformation and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com