Special-shaped board splicing method and device based on inscribed polygon

A polygonal and special-shaped board technology, which is applied in the direction of assembling printed circuits and printed circuit components with electric components, can solve the problems of low utilization rate of Panel boards, low efficiency of panel boards, and low utilization of boards, so as to improve efficiency and reduce Waste, the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to describe in detail the technical content, structural features, achieved objectives and effects of the present invention, the following is a detailed description in conjunction with the embodiments and accompanying drawings.

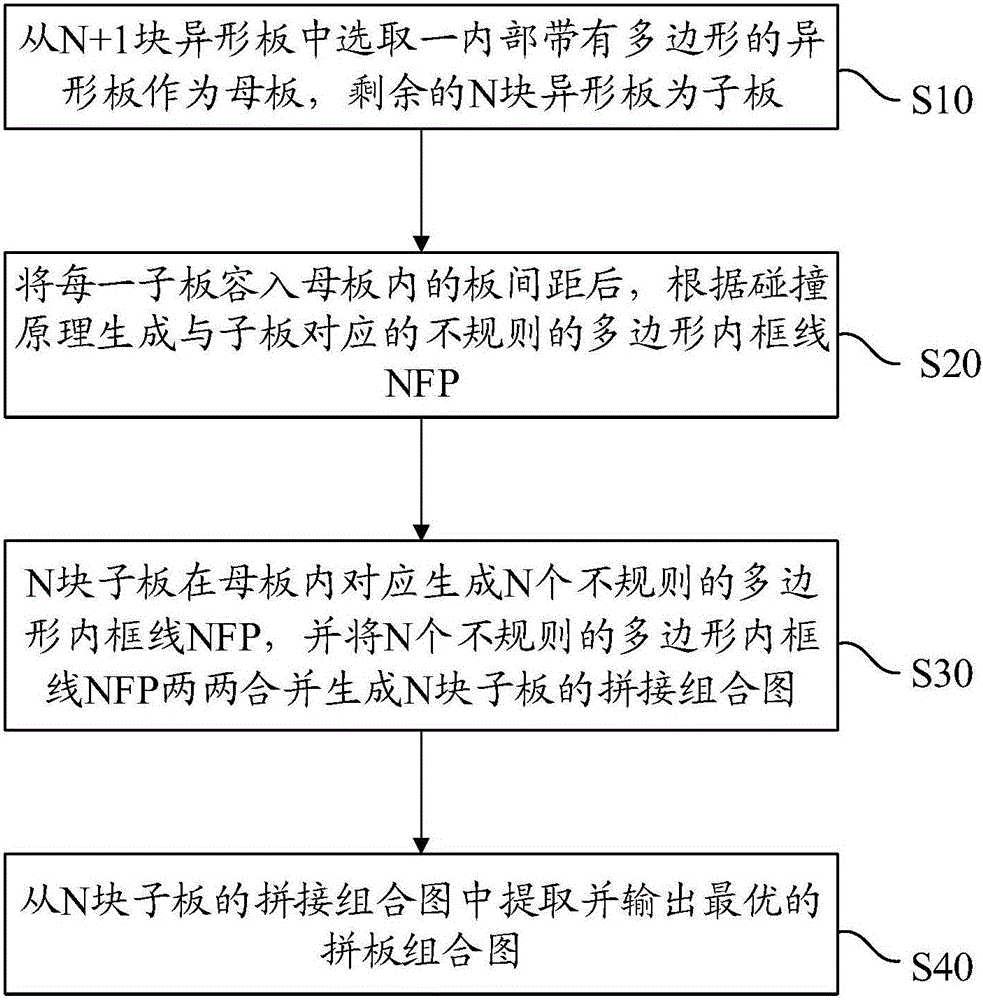

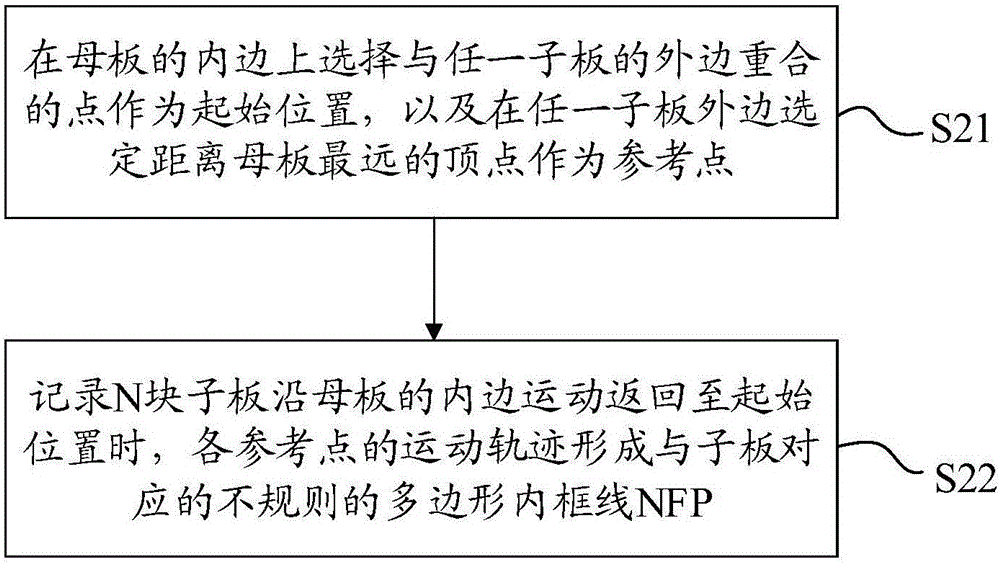

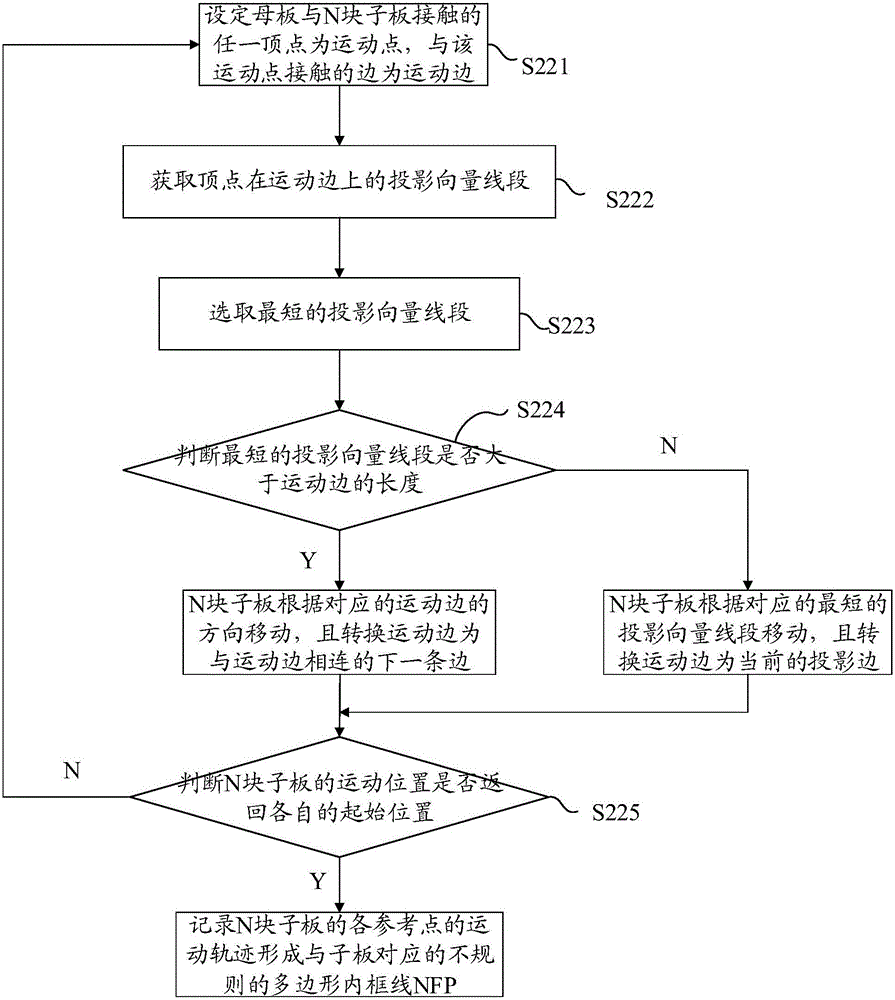

[0035] The most critical idea of the present invention is that the present invention first selects a mother board with polygons inside, and the rest are daughter boards, and then the daughter boards move inside the mother board to form multiple polygonal inner frame lines NFP, and two After the two combinations, a splicing combination diagram of N sub-boards is generated, and the optimal splicing combination diagram is output from the splicing combination diagram of the N sub-boards, which facilitates the direct splicing of the sub-boards to the inside of the mother board, which is beneficial to improve the efficiency of splicing And the utilization rate of the board.

[0036] See figure 1 , The present invention provides a special-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com