Motorcycle tires for driving on uneven ground and tire vulcanization molds

A technology for tire vulcanization molds and motorcycles, which is applied to motorcycle tires, motorcycles, off-road vehicle tires, etc. It can solve the problems of insufficient improvement in the durability of pattern blocks, etc., to achieve the suppression of poor molding, the improvement of durability, and the suppression of defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

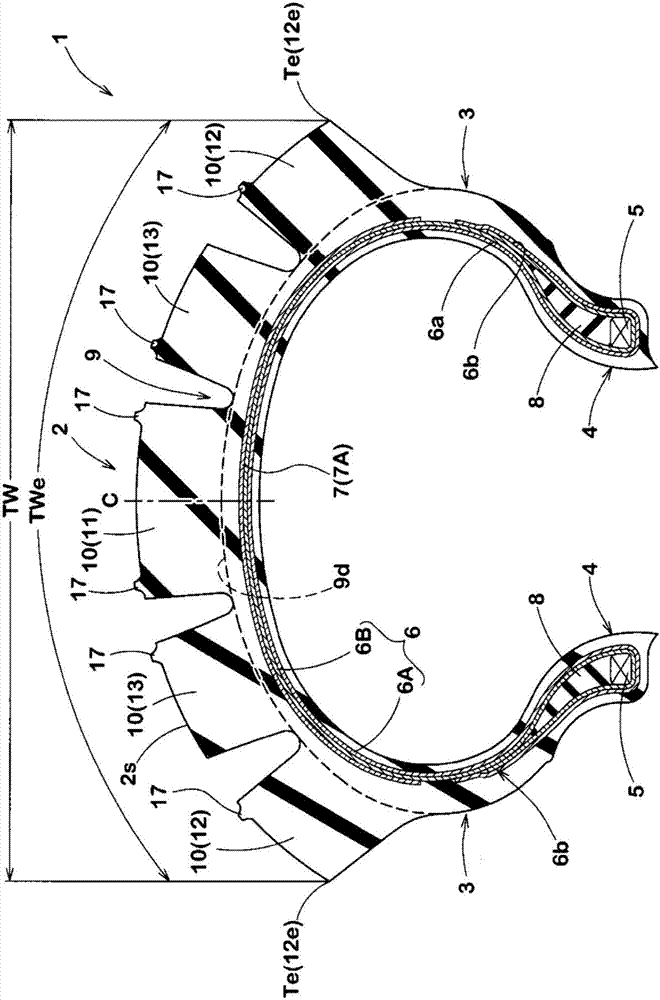

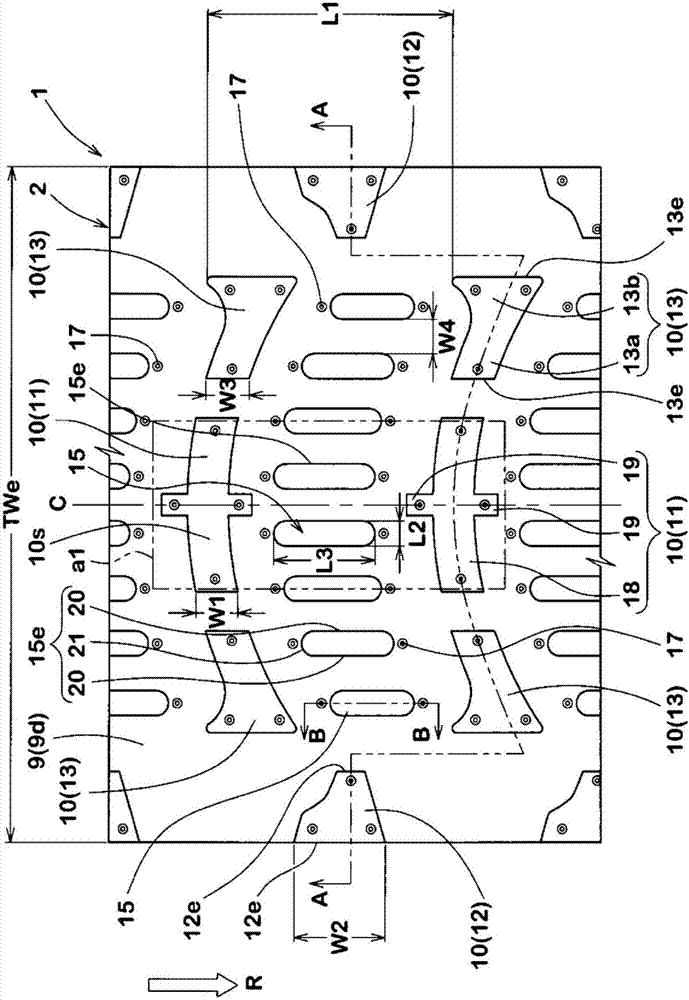

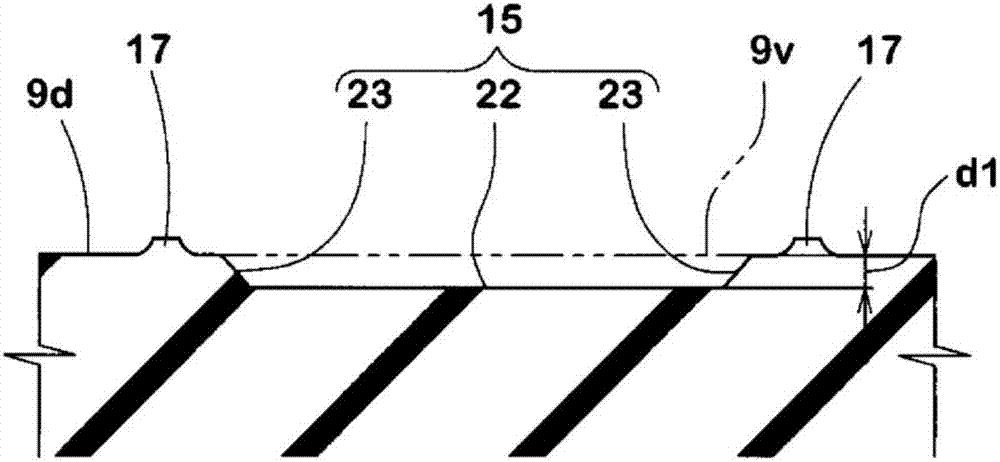

[0069] Based on the specifications in Table 1, a prototype was produced as figure 1 The basic structure shown, and with figure 2 Pneumatic tires for motorcycles with a tread pattern that is a basic pattern for driving on uneven ground. As Comparative Example 1, a tire in which no dimples were provided on the groove bottom surface was trial-manufactured. As Comparative Example 2 to Comparative Example 5, tires were trial-manufactured in which recessed portions were provided on the groove bottom surface, and protruding rubber and its cut-out marks were not provided between the recessed portions and the blocks. Furthermore, these trial tires were mounted on the rear wheels of a test vehicle, and their respective performances were tested. The general specifications and test methods of each test tire are as follows.

[0070] Vehicle used: motorcycle with a displacement of 450cc

[0071] Tire size: 110 / 90-19

[0072] Rim size: 2.50×19

[0073] Internal pressure: 80kPa

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com