torsion beam suspension

A technology of torsion beam suspension and trailing arm, which is applied in the direction of suspension, elastic suspension, interconnection system, etc., can solve the problems of weight increase and large size of trailing arm torsion beam suspension, so as to reduce rigidity and realize Effects of weight reduction and suppression of moment force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

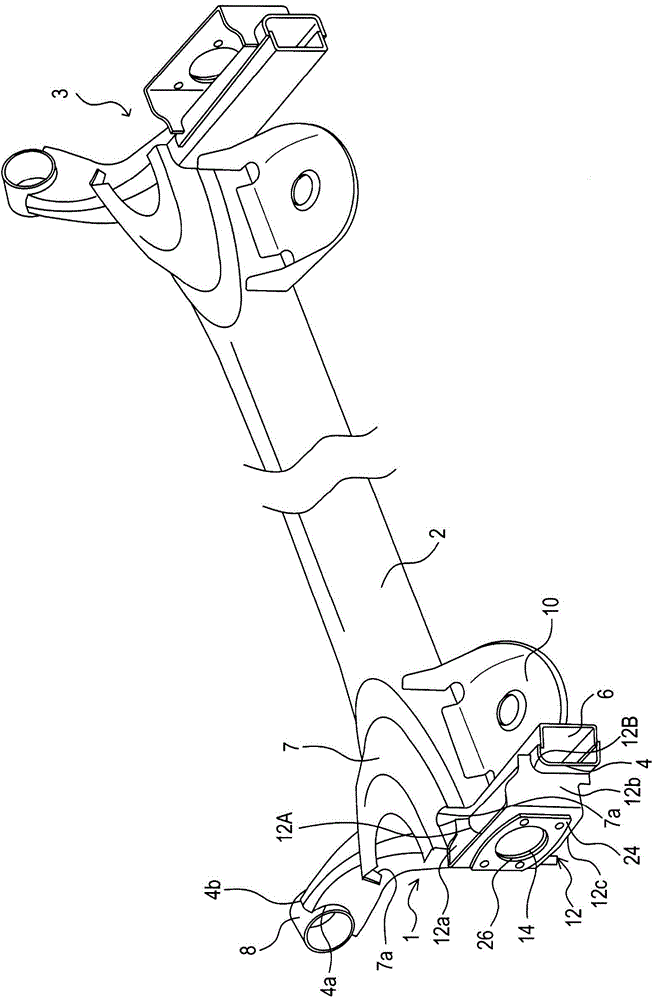

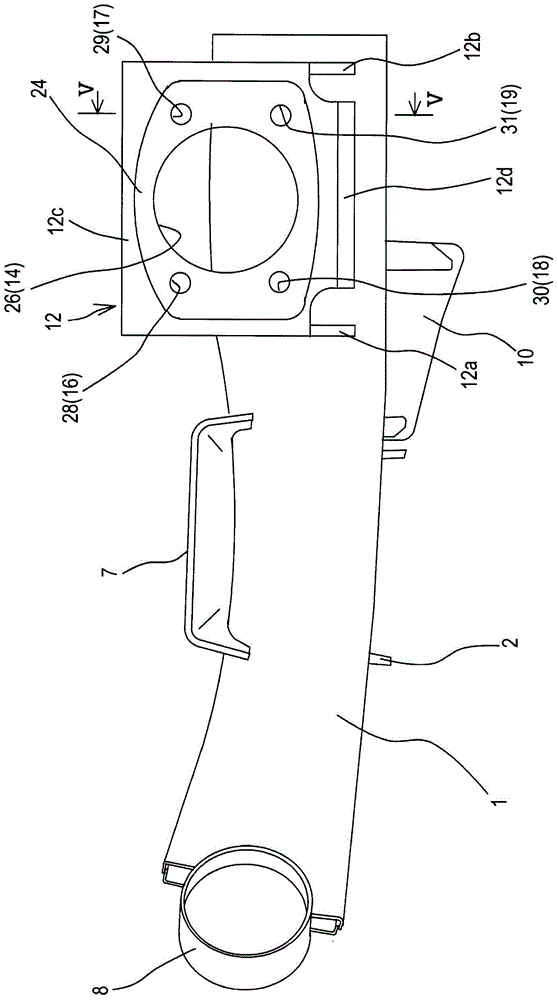

[0033] Such as figure 1 As shown, the torsion beam type suspension of this embodiment is formed by connecting the left trailing arm 1 and the right trailing arm 3 through the torsion beam 2 . Trailing arm 1 and trailing arm 3 are left and right symmetrical. The trailing arms 1 and 3 are formed in a hollow shape.

[0034] The torsion beam 2 is disposed between the trailing arms 1 and 3, and the two ends of the torsion beam 2 are welded to the trailing arms 1 and 3 respectively. Since the torsion beam type suspension of this embodiment is bilaterally symmetrical, in this specification, the trailing arm 1 on the left will be described as a center.

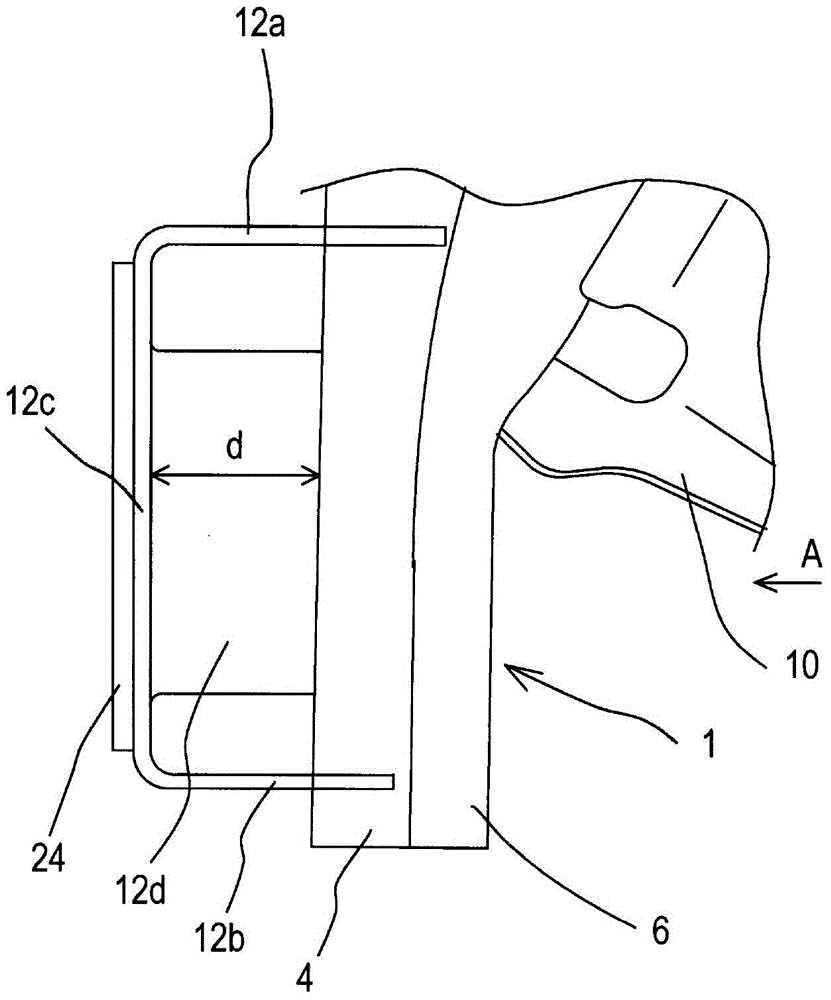

[0035] Such as figure 1 , Figure 5 As shown, the trailing arm 1 is formed by butting a pair of arm members 4 and 6 that can be divided in the width direction of the vehicle body along the axial direction of the trailing arm 1 .

[0036] The pair of arm members 4 and 6 are each formed by press molding so that the cross-sectiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com