Thumb hole mold plate and method for applying same

A template and thumb technology, which is applied in the field of clothing equipment, can solve the problems of complexity, aggravating the work burden of operators, and low clothing production efficiency, and achieve the effect of simplifying the sewing process, facilitating the thumb hole sewing operation, and reducing the work burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended Figures 1 to 12 The thumb hole template provided by the present invention is described in detail.

[0041] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In the embodiments, parts of the same configuration are given the same reference numerals and descriptions are omitted.

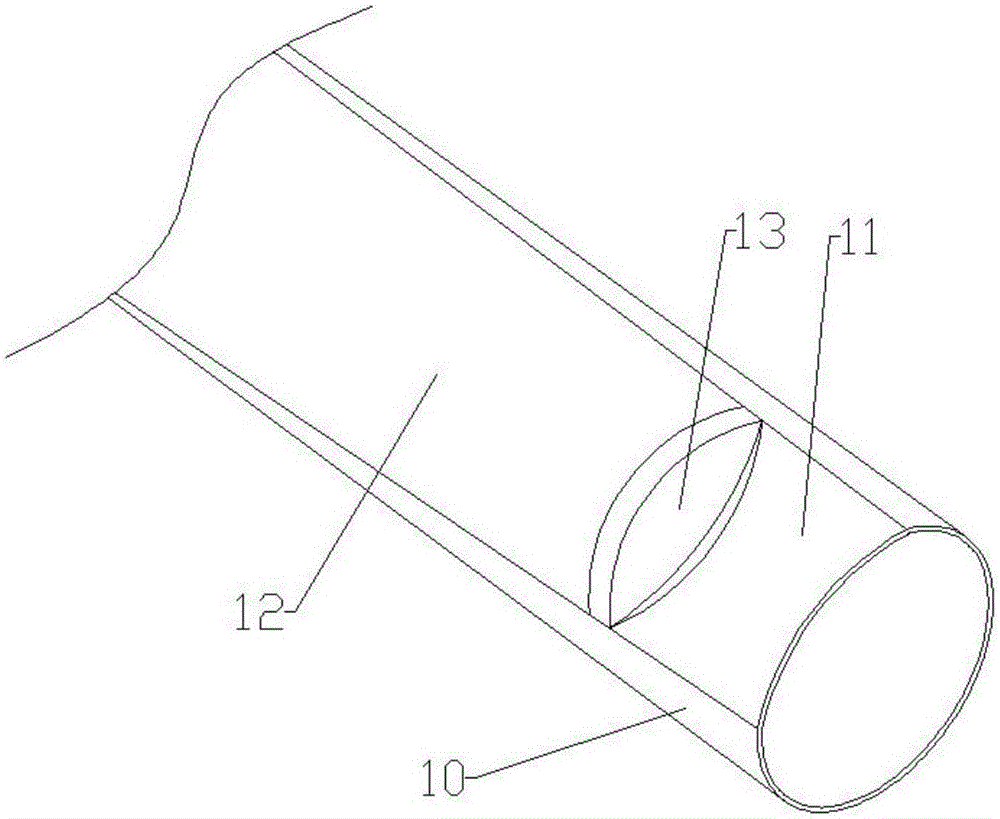

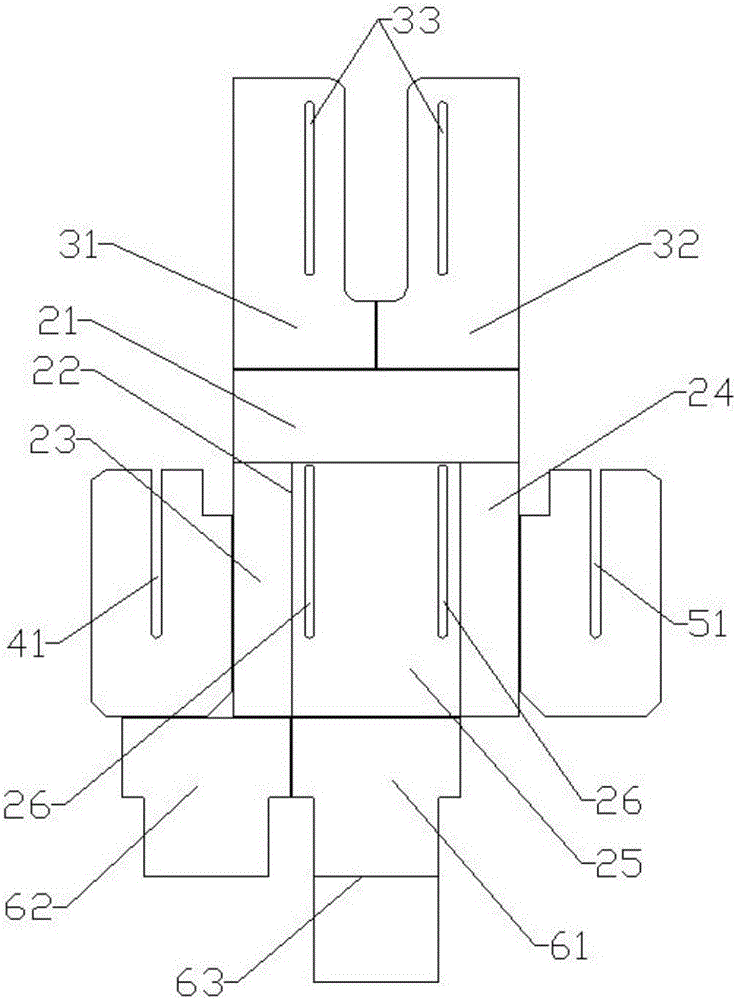

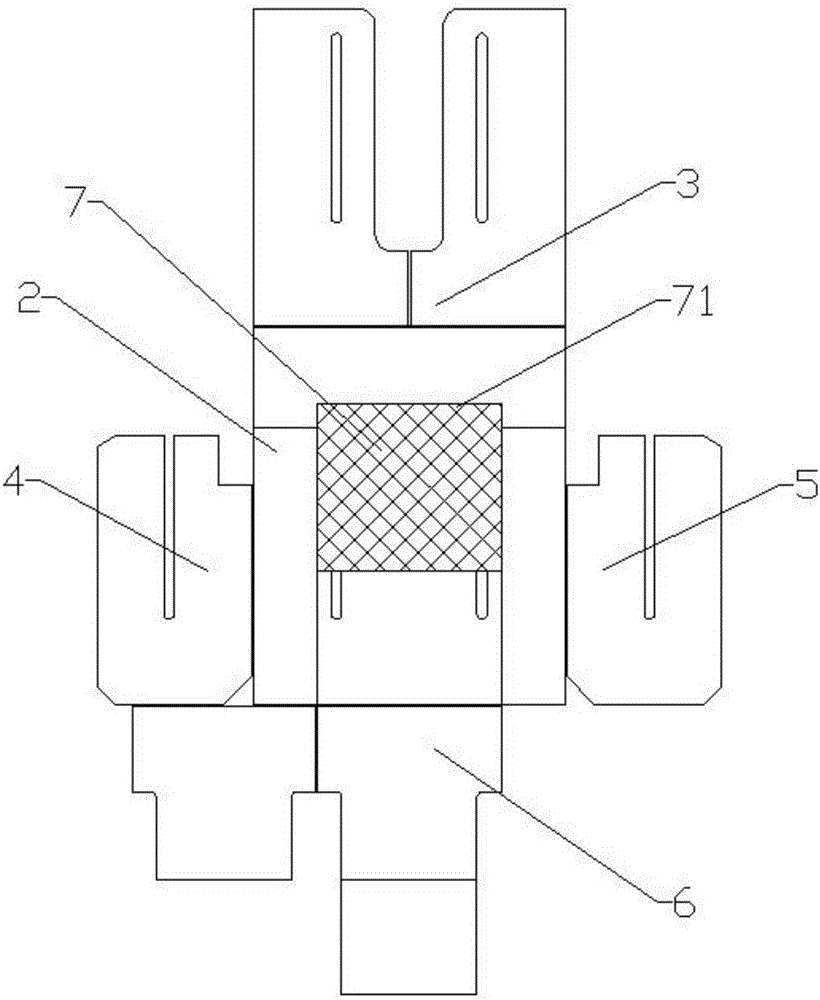

[0042] figure 2 It is a schematic diagram of the unfolded structure of an embodiment of a thumb hole template, Figure 3 to Figure 11 It is a specific application state diagram of an embodiment of a thumb hole template, such as Figure 2 to Figure 11 as shown in

[0043] The thumb hole template provided by the present invention includes a middle bottom plate 2 , an upper movable plate 3 , a lower movable plate 6 , a left movable plate 4 , and a right movable ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap