Optical fiber induction layer and monitoring system thereof

A technology of optical fiber sensing and optical fiber, which is applied in the direction of transmitting sensing components, application, and measuring force by using optical devices, and can solve the problems of optical fiber sensing layer to distinguish sensing blind areas, small application range, and uneven sensing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

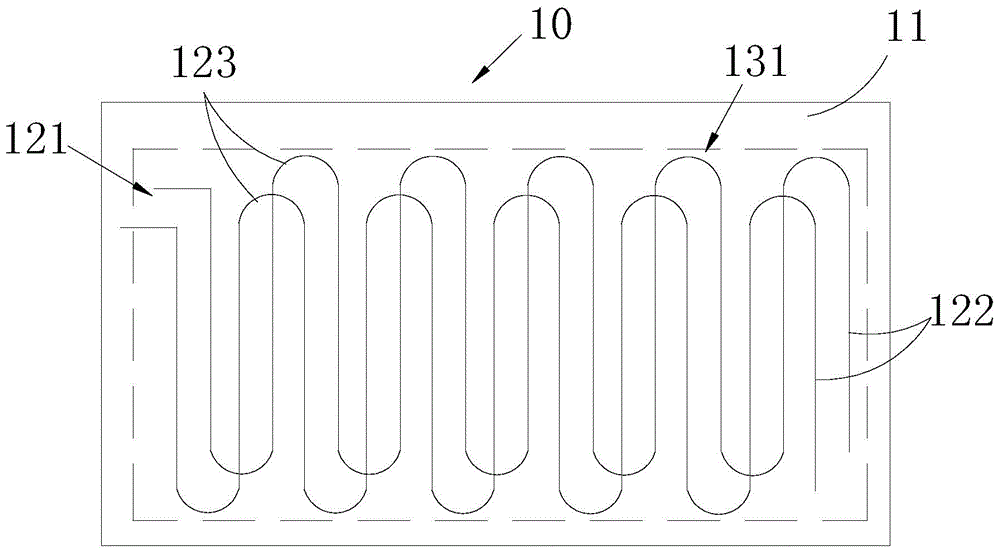

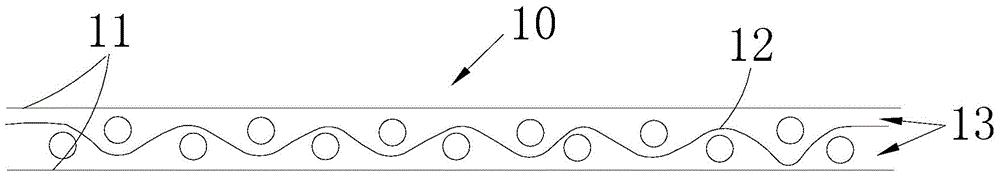

[0047] Such as image 3 with Figure 4 As shown, the diameters of the bends 121 and 123 of the same optical fiber row section 122 on the same interlayer 13 are equal, so that the diameters of the bends 123 are equal and change regularly, which is beneficial to the arrangement of the wiring 121 on the same optical fiber row section 122; the same interlayer The diameters of the bends 123 of the routing 121 of different fiber segments 122 on 13 gradually increase or decrease along the second direction, because the fiber segment 122 with the smaller diameter of the bend 123 gradually fills up and fits into the diameter of the larger bend 123 In the optical fiber line section 122, therefore, the routing 121 of the optical fiber line section 122 on the pressure sensitive component film 11 in this embodiment will show a transition trend in which the diameter of the bend 123 gradually increases or decreases, so that the pressure sensitive component film 11 The routing 121 of the opti...

no. 2 approach

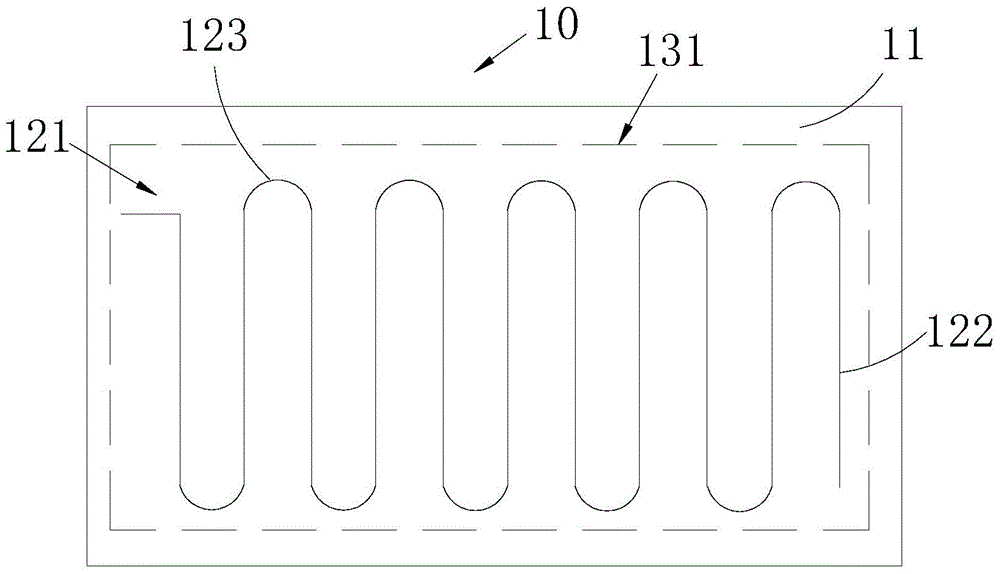

[0049] Such as image 3 with Figure 5 As shown, the diameters of the bends 123 of the wires 121 on all fiber segments 122 in the same interlayer 13 are equal. In this way, the diameters of the bends 123 of all the optical fiber segments 122 are equal and change regularly, which is conducive to the regular, uniform and relatively dense distribution of the lines of the optical fiber segments 122 on the pressure sensitive component film 11. Similarly, the above-mentioned optical fiber sensing layer 10 The sensitivity is uniform, the light attenuation value is relatively consistent, the sensitivity is high and adjustable, and the resolution is high.

no. 3 approach

[0051] Such as image 3 with Image 6 As shown, the diameters of the bends 123 of the wires 121 on the same optical fiber row section 122 in the same interlayer 13 are different, and two adjacent optical fiber row sections 122 are symmetrical about the center. In this way, every two optical fiber row segments 122 form a group of segments, and multiple groups of segments are distributed in parallel on the pressure sensitive component film 11. Similarly, the regular changes of the optical fiber row segment 122 routing 121 are conducive to making the above-mentioned optical fiber sensing layer 10 sensitive. The brightness is uniform, the light attenuation value is relatively consistent, the sensitivity is high and adjustable, and the resolution is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com