Heavy type part spraying device

A spraying device and component technology, which is applied in the field of heavy-duty parts spraying device, can solve the problems of insufficient spraying, insufficient paint pressure, high height, etc., and achieve the effect of avoiding insufficient spraying and excessive spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

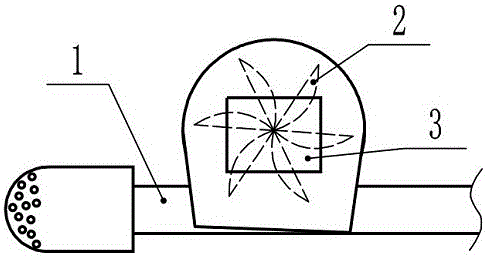

[0023] Such as figure 1 , a heavy-duty parts spraying device, including a six-axis articulated robot and a spray gun 1 installed at the end of the six-axis articulated robot, the spray gun 1 is provided with a pressure regulating device, and the pressure regulating device includes a shell installed on the spray gun 1 The body, the turbine blade 3 installed in the casing and rotatable relative to the casing, and the frequency conversion motor 2 connected with the turbine blade 3, the inside of the spray gun 1 has a paint channel for conveying paint, the lower part of the turbine blade 3 Located in the paint channel inside the spray gun 1;

[0024] The variable frequency motor 2 is connected to a control system that is connected to the six-axis articulated robot and controls the movement of the six-axis articulated robot;

[0025] When spraying heavy pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com