Low-cost small-sized bag feeding type nut packaging machine

A low-cost, packaging machine technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of high labor cost, unsanitary, bulky, etc., achieve good bag clamping effect, improve production efficiency and effect, volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

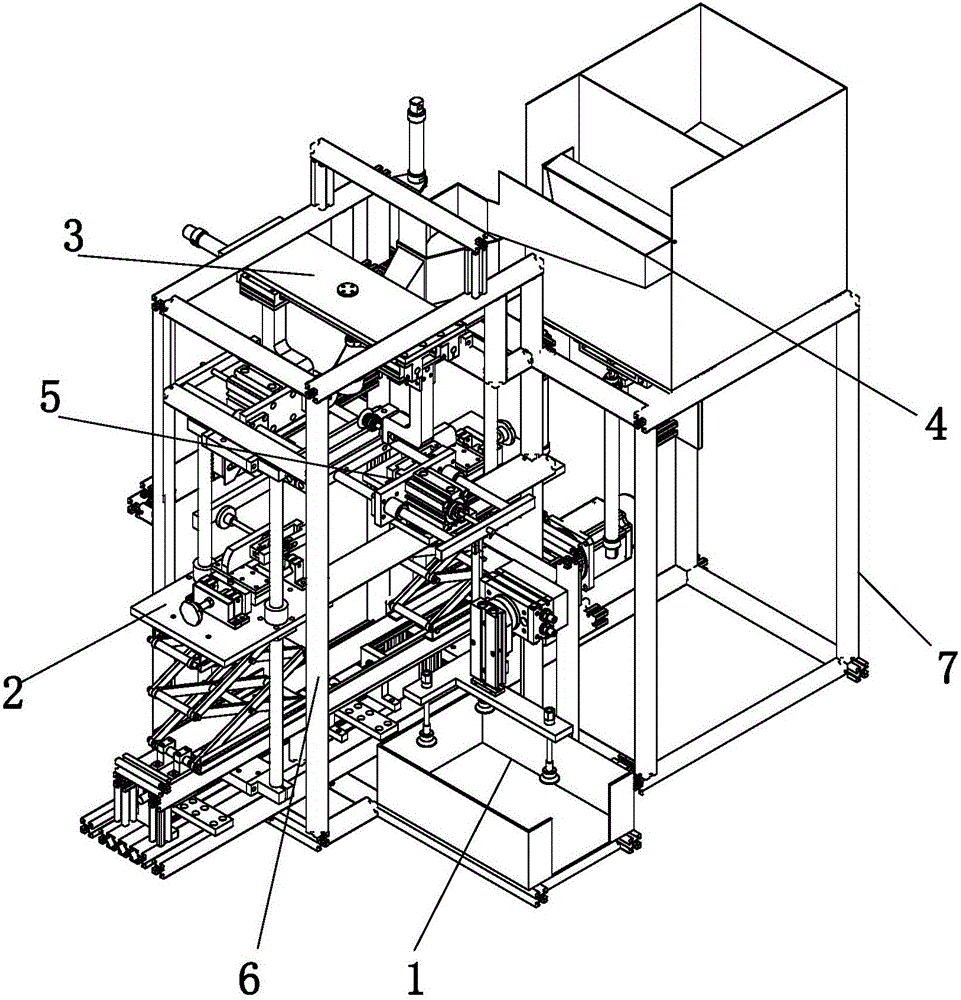

[0030] Example. A low-cost small-sized bag-feeding nut packaging machine, which consists of figure 1 As shown, the main frame 6 and the sub-frame 7 are included, and the main frame 6 is provided with a bag-taking device 1, a bag-clamping device 2, a bag-opening device 3 and a bag-sealing device 5 connected in sequence, and the bag-opening device 3 side The part is connected with the weighing and blanking device 4 arranged on the sub-frame 7 . The bag taking device 1 sucks the bag to the bag clamping conveying device 2, clamps the bag through the entraining conveying device 2, and conveys it to the bag opening device 3 to open the bag on both sides, and then the weighing and unloading device 4 weighs the pre-weighed The material falls into the bag, and then the bag delivery device 2 transports the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com