Automatic chiseling equipment for the bottom surface of structures

A structure and bottom surface technology, applied in the field of automatic chiseling equipment for the bottom of structures, can solve the problems of dust being harmful to the human body, unsatisfactory chiseling effect, high labor intensity, etc., and achieve good chiseling quality, low cost and high applicability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

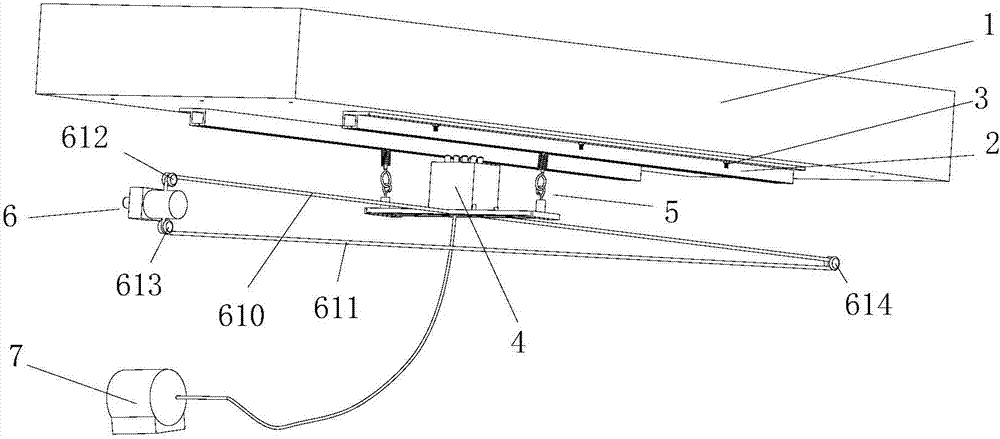

[0031] Taking the maintenance and strengthening of the bridge floor as an example below, the present invention will be further described in detail in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments.

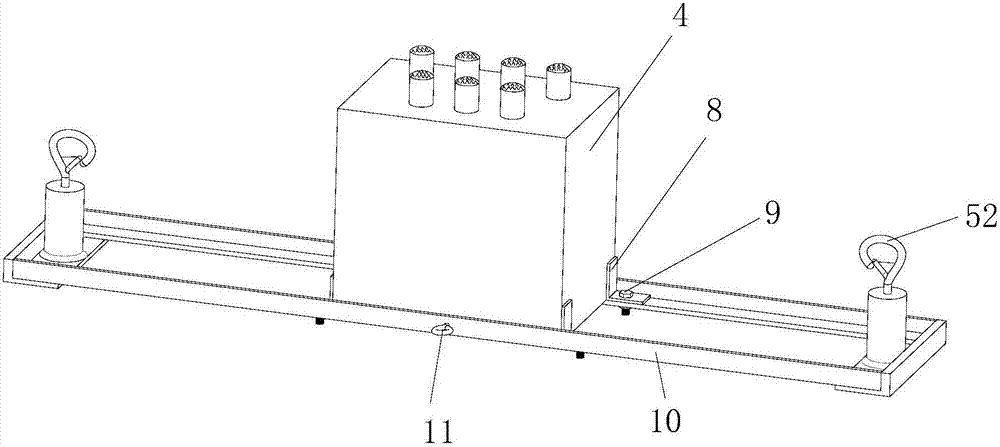

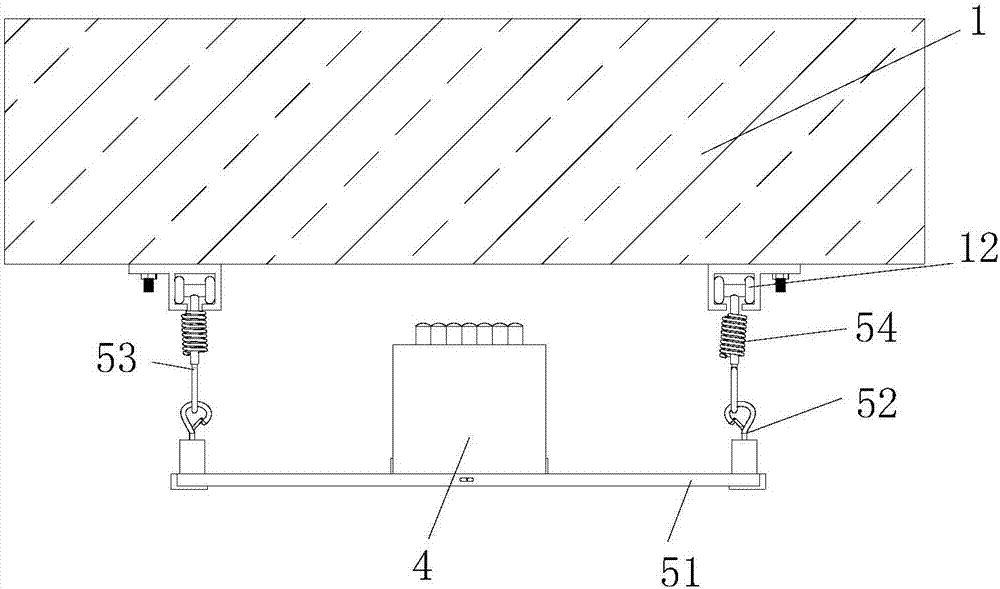

[0032] Such as Figure 1 to Figure 4 As shown, a kind of automatic chiseling equipment for the bridge bottom plate comprises a chisel machine 4 and a chisel suspension system 5, and the chisel suspension system 5 includes a suspension 51 and two parallel shafts arranged on the bridge bottom 1. The guide rail 2, the area between the two guide rails 2 is the area that needs to be chiseled and cleaned, the chisel machine 4 is located between the two guide rails 2, and each guide rail 2 is equipped with a And the traveling wheel 12 that can move along guide rail 2, suspension 51 is arranged on the below of bridge base plate 1, and chisel machine 2 is installed on the suspension 51, and the two ends of suspension 51 pass throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com