Free sandwich heat-preservation wall connection element

A technology for thermal insulation walls and connectors, which can be used in thermal insulation, walls, building components, etc., and can solve problems such as damage to the EPS module of the thermal insulation layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

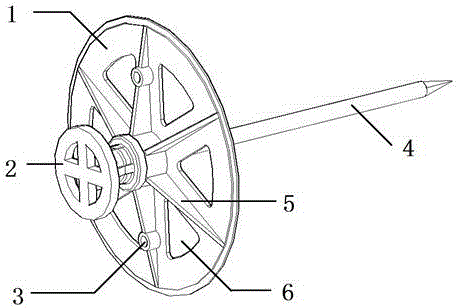

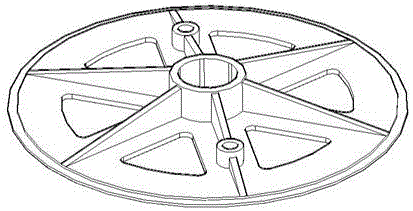

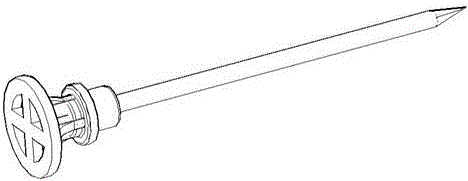

[0020] to combine Figure 1-Figure 3 . The first embodiment of the present invention includes a connecting rod and a support plate 1, the connecting rod is composed of an end rod 2 and a tail rod 4, the front end of the end rod has an end plate, and the rear end of the end rod is a plug-in positioning end, The tail rod is installed in the insertion positioning end of the end rod, and there is a through hole in the middle of the support disc, and the connecting rod is inserted in the through hole in the middle of the support disc and the two are closely matched. The end rod is made of plastic material, the tail rod is made of metal material, the tail rod is inserted into the end rod and the two are closely matched. The distance between the inner surface of the support plate and the outer surface of the end plate is equal to the design thickness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com