Method and device for position calibration

A calibration plate and coordinate technology, applied in the field of film loading technology and optics, can solve the problems such as the inability to eliminate small deviations and the difficulty in improving the precision of film loading, achieve simple and accurate verification and correction of deviations, eliminate small deviations, and improve the accuracy of equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

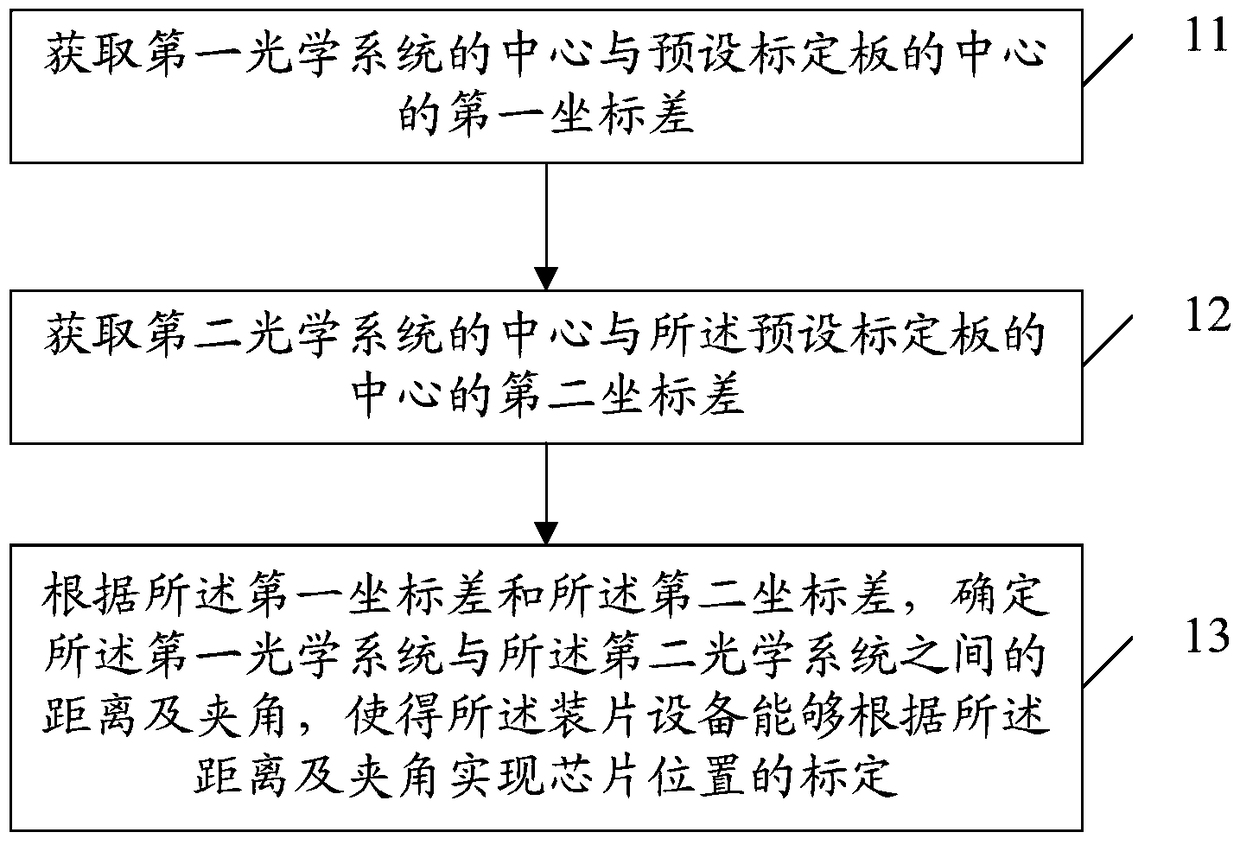

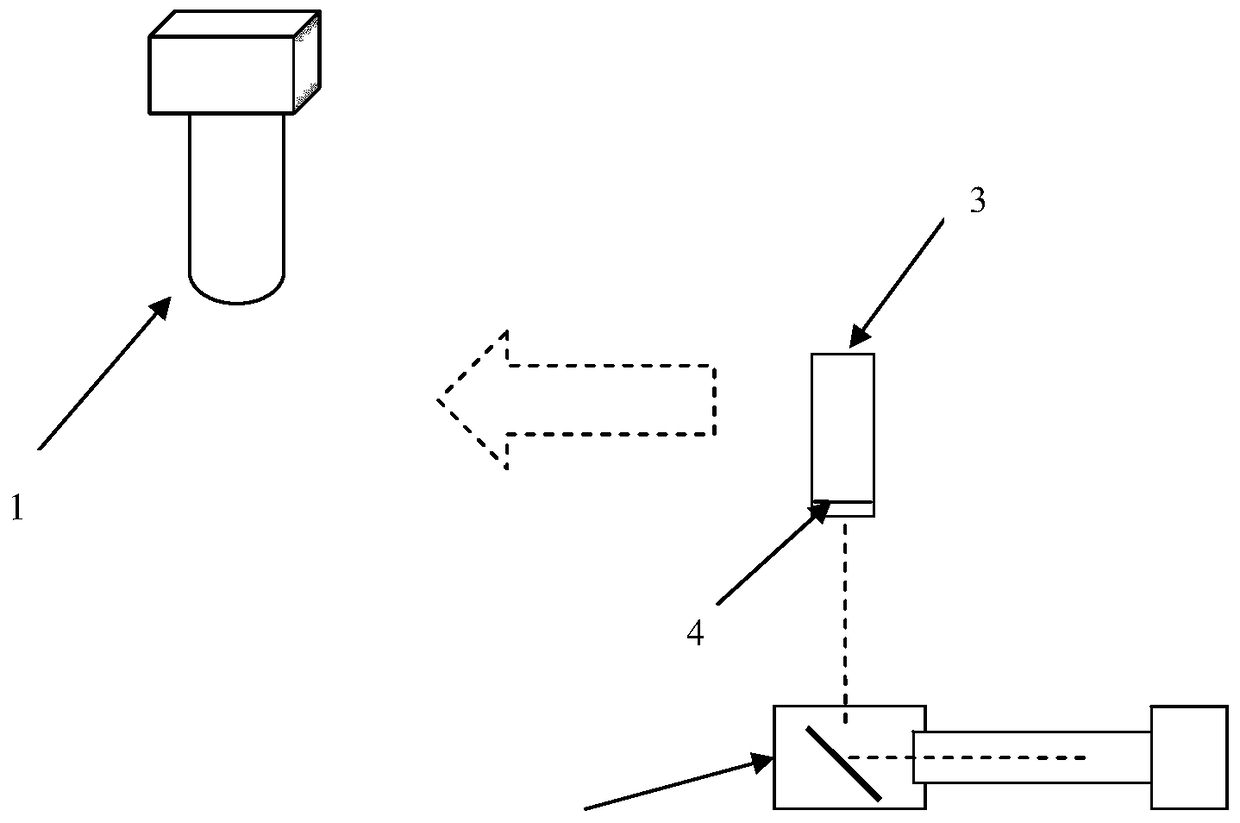

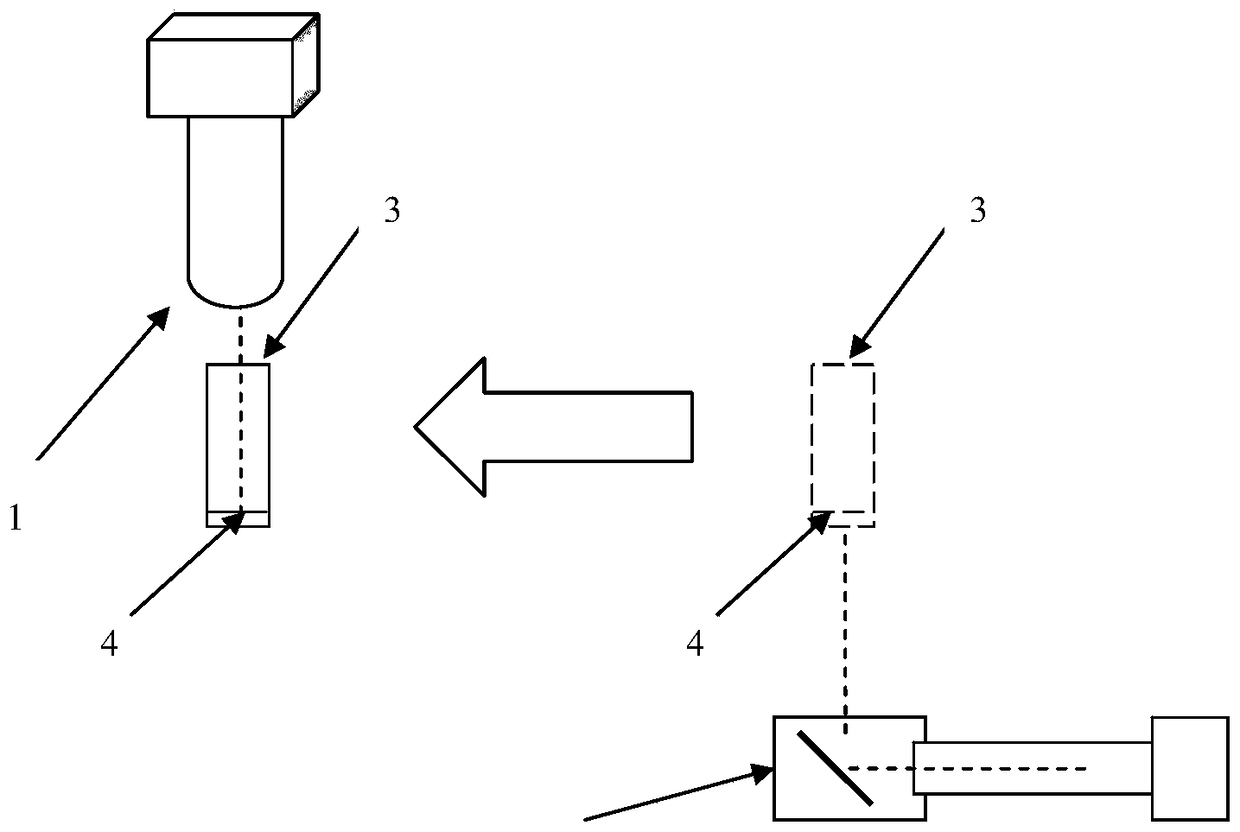

[0052]The present invention aims at the problem in the prior art that the chips picked up by the chip loading equipment are loaded directly without alignment, and there is a slight deviation, which makes the chip loading precision not high. Previously, the precise distance and angle between the first optical system and the second optical system were determined through the first coordinate difference and the second coordinate difference, so that the loading equipment can realize the calibration of the chip position according to the distance and the angle, eliminating the The slight deviation that may occur during the chip picking process meets higher chip loading accuracy requirements; at the same time, it solves the problem of inconsistent coordinate syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com