Pre-alignment system and method for bonding flip chip

A flip-chip and pre-alignment technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of difficulty in improving chip loading accuracy and inability to eliminate small deviations, so as to improve accuracy and efficiency, The effect of accurately correcting deviations and eliminating small deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

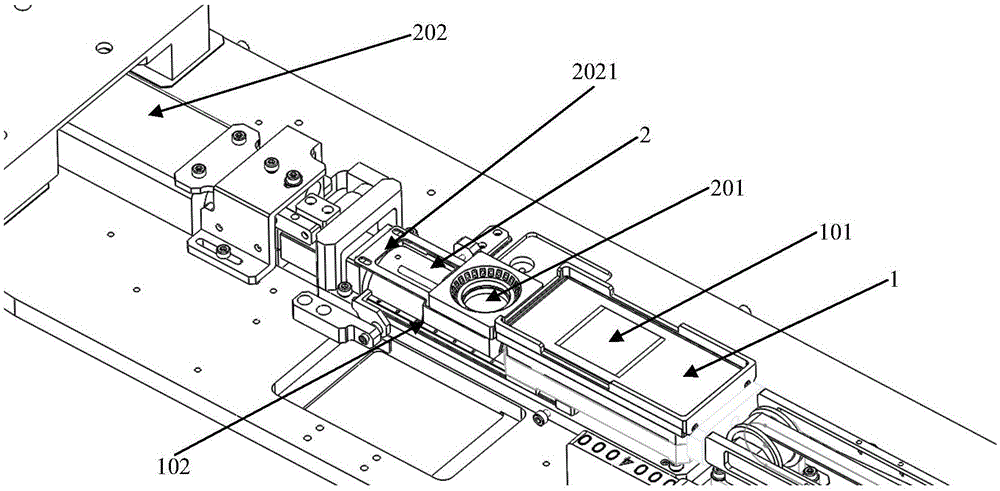

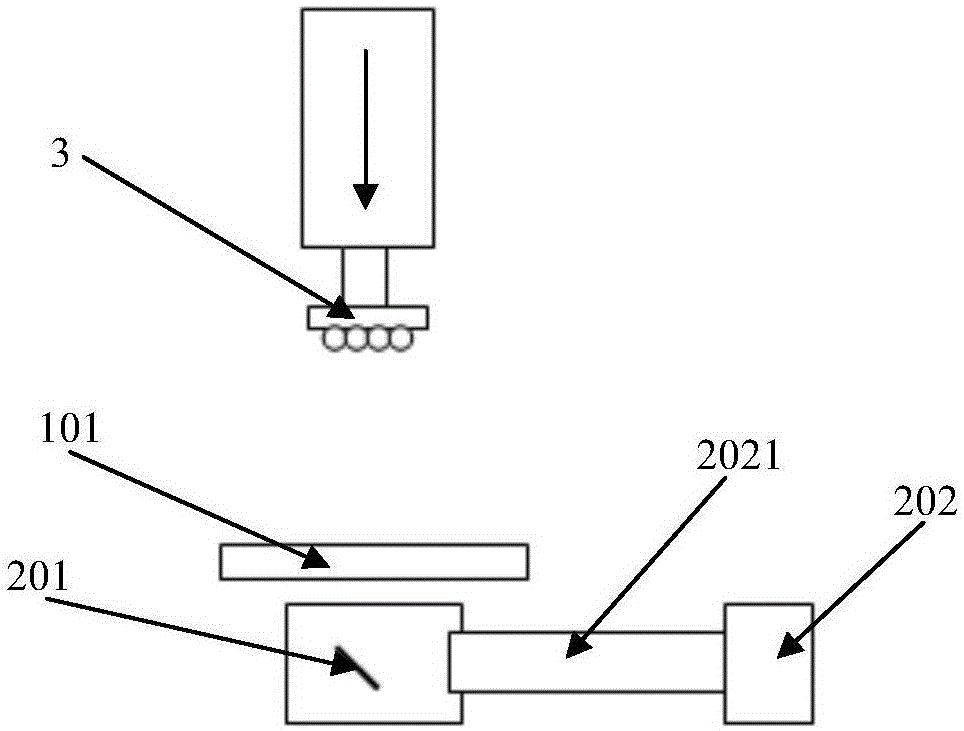

[0038] According to one aspect of the present invention, a pre-alignment system for flip-chip bonding is provided, such as figure 1 As shown, the pre-alignment system includes:

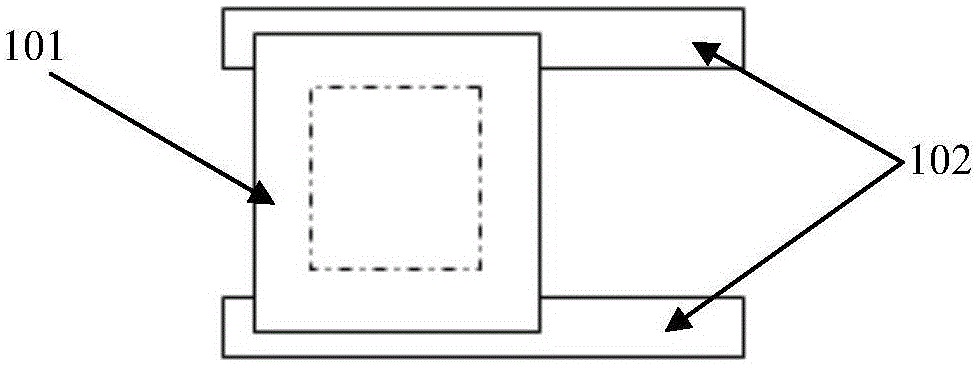

[0039] The flip-chip dipping structure 1 installed on the workbench, the flip-chip dipping structure 1 includes: a dipping plate 101 for flip-chip dipping; mechanical slide rails slidingly connected to both sides of the dipping plate 101 102; a motor electrically connected to the mechanical slide rail 102 and used to drive the mechanical slide rail 102 to slide;

[0040] The up-view optical structure 2 installed on the workbench, the up-view optical structure 2 includes: a turning prism 201 fixed between the mechanical slide rails 102 and located below the dipping plate 101; an industrial camera for obtaining flip-chip images 202; Wherein, the turning prism 201 is connected with the industrial camera 202 through the lens 2021 of the industrial camera 202, and

[0041] Such as image 3 As shown in ,...

Embodiment 2

[0050] In an embodiment of the present invention, a pre-alignment method for flip-chip bonding is provided, which is applied to the above-mentioned pre-alignment system for flip-chip bonding. The pre-alignment system includes: Flip-chip dipping structure 1, the flip-chip dipping structure 1 includes: a dipping plate 101 for flip-chip dipping; mechanical slide rails 102 slidingly connected to both sides of the dipping plate 101; 102 is electrically connected, and is used to drive the motor for sliding the mechanical slide rail 102; the upward-looking optical structure 2 installed on the workbench, the upward-looking optical structure 2 includes: fixed between the mechanical slide rails 102, and located below the rubber dipping plate 101 A turning prism 201; an industrial camera 202 for obtaining flip-chip images; wherein, the turning prism 201 and the industrial camera 202 are connected through the lens 2021 of the industrial camera 202, and are located above the glue board 101 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com