Systems and methods for studying blast stress wave interaction mechanisms

A technology of explosion stress and mechanism, which is applied in the direction of educational appliances, instruments, teaching models, etc., can solve the problem that the effect of explosion stress wave is less than the mutual superposition of explosion stress wave

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with specific embodiments.

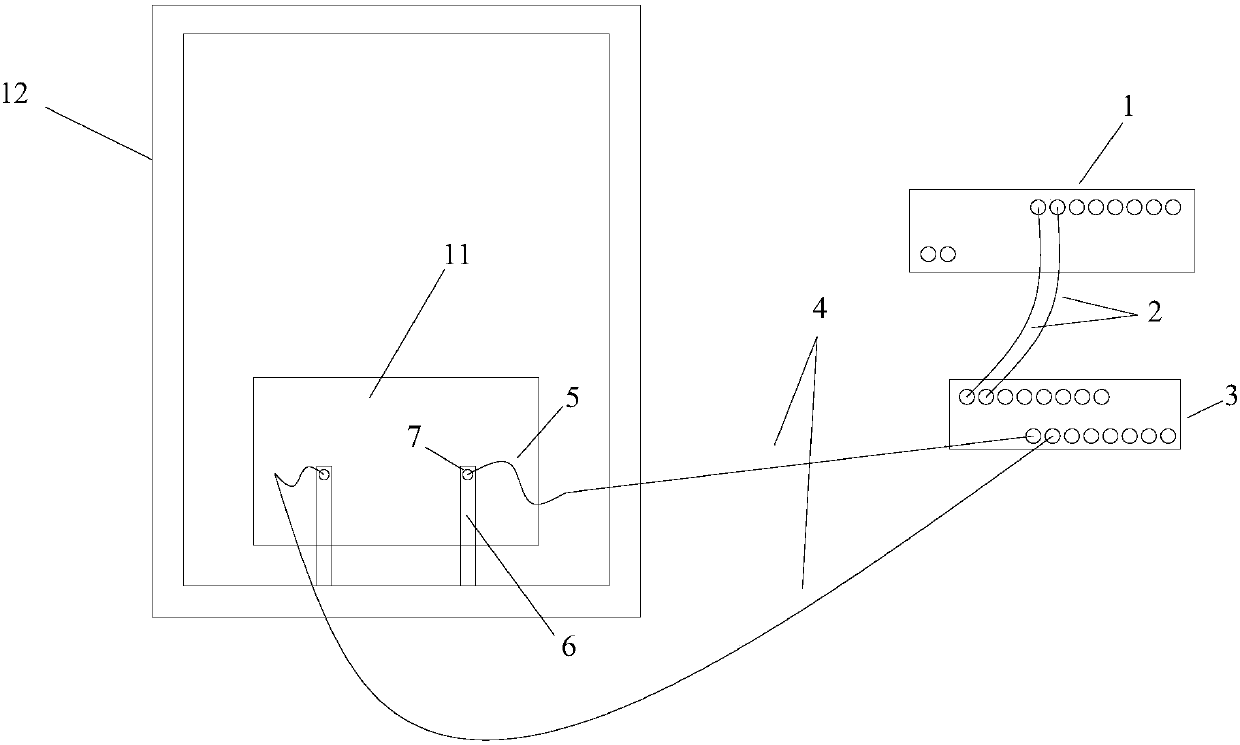

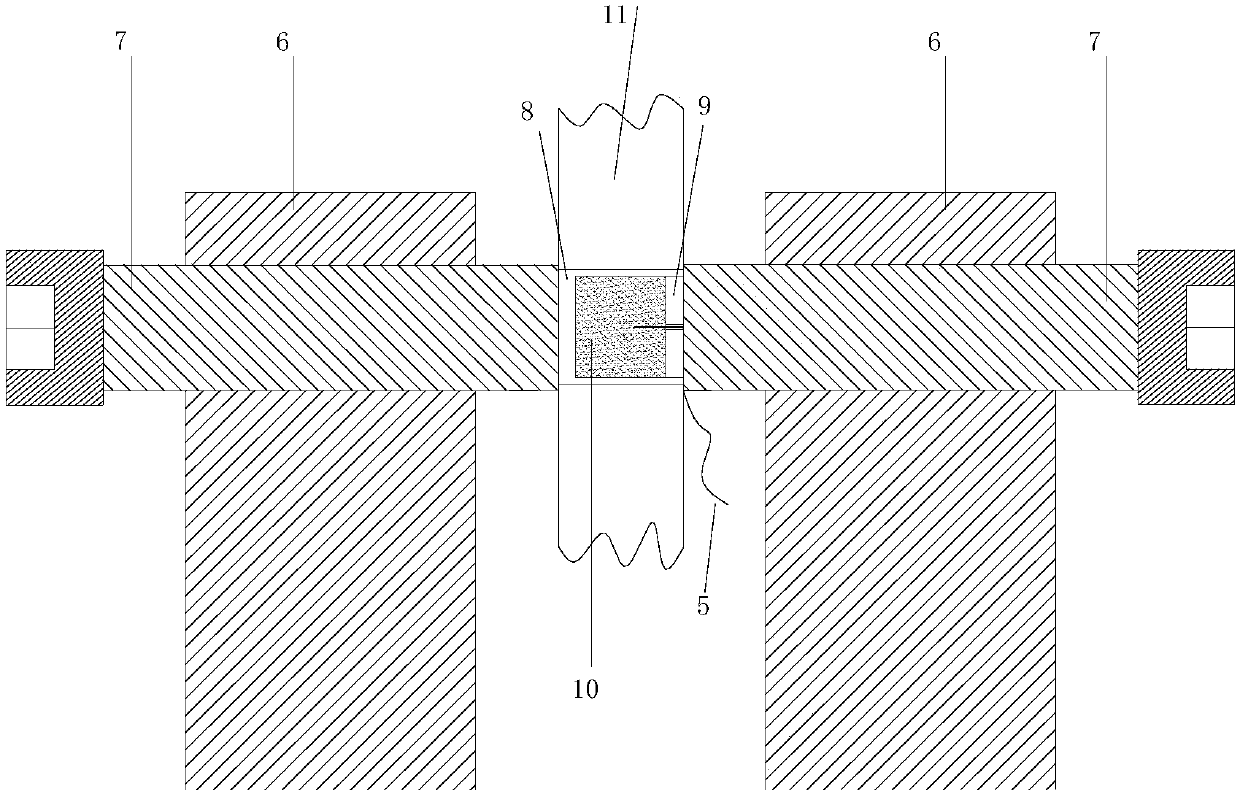

[0023] refer to Figure 1-2 , the system for studying the interaction mechanism of explosion stress waves includes a bracket 12, an explosive charge 8, a charge seal cover 9, an explosive 10, a test piece 11, a fixing bolt 7, a test piece fixture 6, a detonation probe 5, and an explosive charge 8 It is a hollow cylinder with one end closed, the outer diameter of the cylinder is the same as the diameter of the test piece 11 blast hole, the height of the cylinder is the same as the thickness of the test piece 11, and the explosive can be installed inside the cylinder; the diameter of the charge sealing cover 9 is the same as the inner diameter of the explosive charge 8 Same, there is a small round hole in the center of the circle, and the detonating probe 5 can pass through the small round hole; the specimen fixture 6 is equipped with a fixing bolt 7 for fixing the specimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com