Heat-conduction deflagration-delayed fracturing device and construction method

A fracturing and deflagration technology, which is applied in the direction of earthwork drilling, mining fluid, wellbore/well components, etc., to achieve the effect of solving the difficulty of detonation, simple device design, and heat transfer detonation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

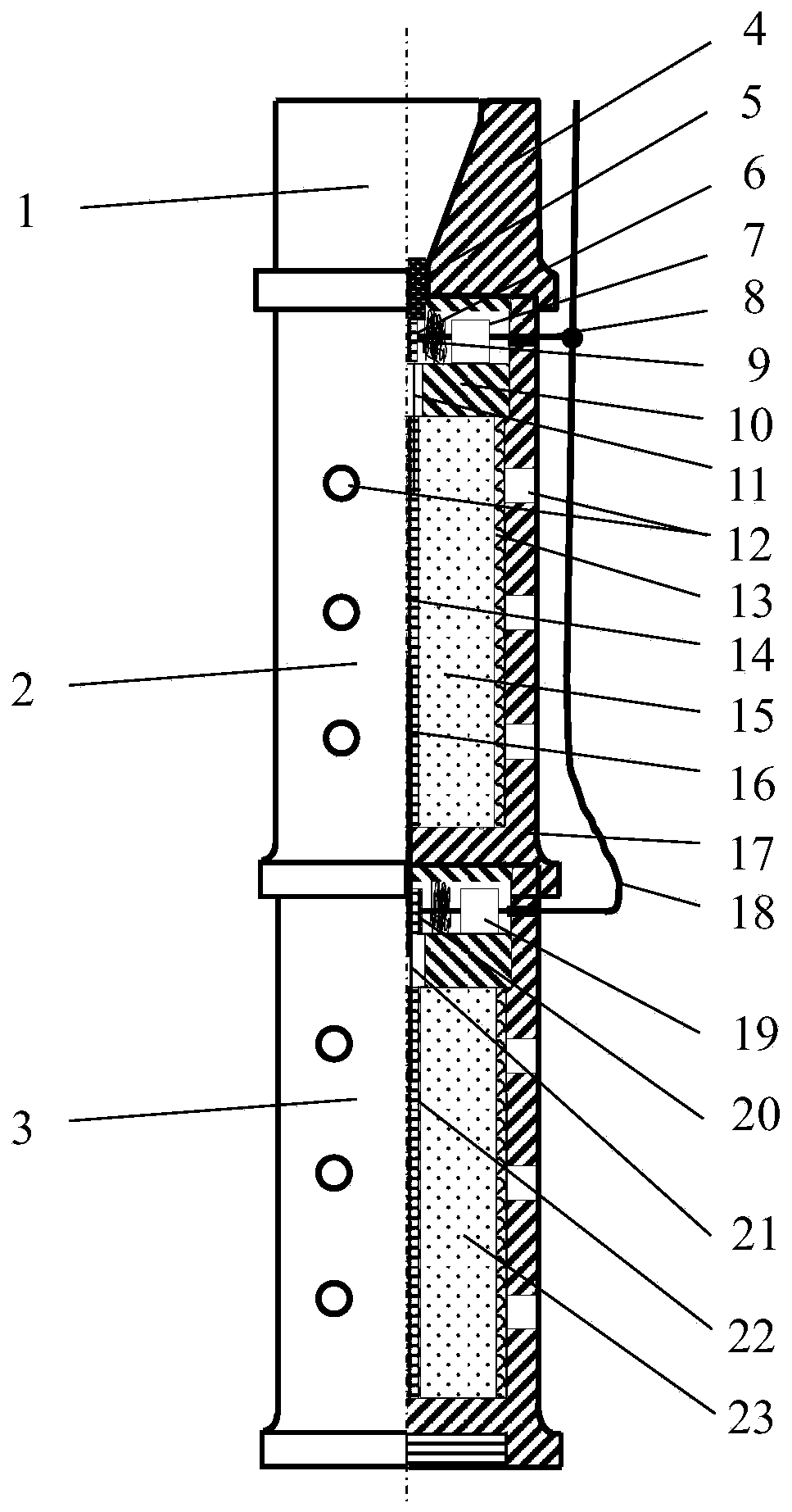

[0038] like figure 1 As shown, this embodiment provides a heat conduction delayed deflagration fracturing device, which includes a bludgeoning guide 1, a first subsection 2 and a second subsection 3 arranged sequentially from top to bottom; the bottom of the bludgeoning guide 1 A struck element 5 is provided, and the bottom of the struck element 5 corresponds to the first high-temperature-resistant ignition charge 14 in the first short section 2, and the first high-temperature-resistant ignition charge 14 is connected with the first An ignition and detonation mechanism, the first ignition and detonation mechanism is used to detonate the first high temperature resistant propellant 15 in the first short joint 2; the bottom of the first short joint 2 is provided with a heat conduction rod 16, and the heat conduction The bottom of the rod 16 protrudes into the second short section 3 and is in contact with the flammable powder 20 in the second short section 3, and a second ignition...

Embodiment 2

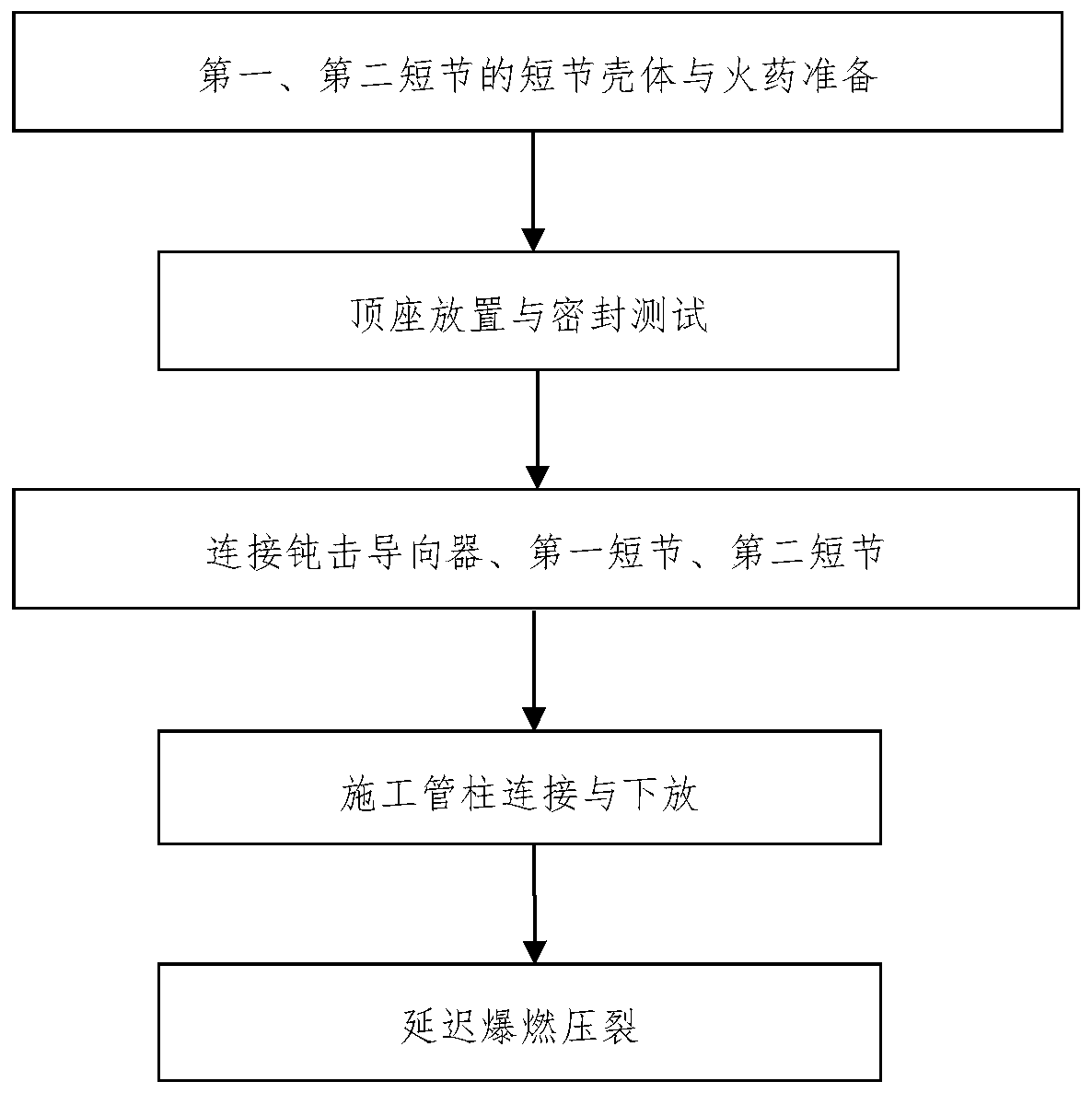

[0049] This embodiment provides a construction method using the heat conduction delayed deflagration fracturing device in Embodiment 1, which includes the following steps:

[0050] The first step is to assemble the first short joint 2 and the second short joint 3, the process is as follows:

[0051] S101. Preparation of sub-joint housing 17 and gunpowder: according to the depth, pressure, temperature of the construction target layer and the well diameter conditions of the construction shaft, select the sub-joint housing 17 of an appropriate size, and the maximum outer diameter of the sub-joint housing 17 is smaller than the wellbore Inner diameter, high-temperature-resistant propellant and high-temperature-resistant igniting powder should be lower than the target layer temperature. When the construction shaft has a large well inclination, pulleys should be symmetrically added to both ends of the nipple casing 17 to ensure heat conduction during lifting and lowering. The delaye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com