A rotary automatic reversing switch

An automatic reversing and rotating technology, applied in the direction of electric switches, electrical components, circuits, etc., can solve problems such as poor contact, low efficiency, and easy failures, and achieve high stability, large capacity, and low loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

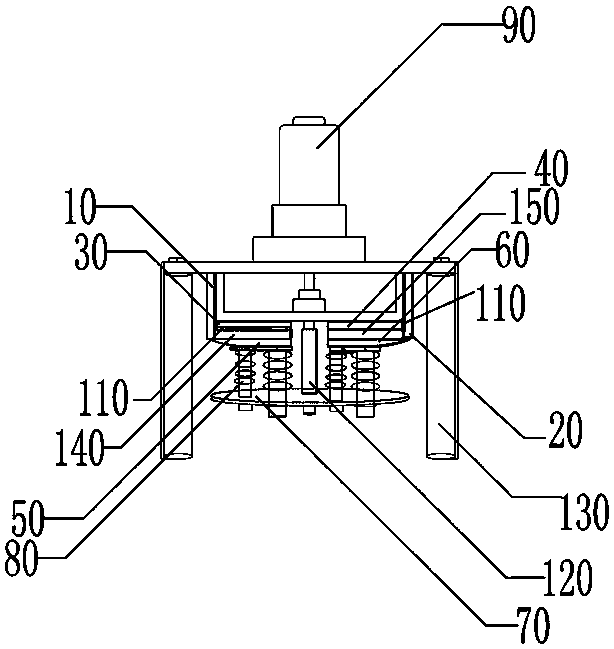

[0023] A rotary automatic reversing switch, (such as figure 1 (shown) includes a bracket 130, and a motor 90 is arranged on the bracket 130, and the motor 90 is used to drive the rotating disk to rotate, and a DC motor can be used for forward and reverse rotation.

[0024] The first output electrode 30 and the second output electrode 40 are sequentially arranged on the support 130 , and the first output electrode 30 and the second output electrode 40 are located on both sides of the center of the support 130 .

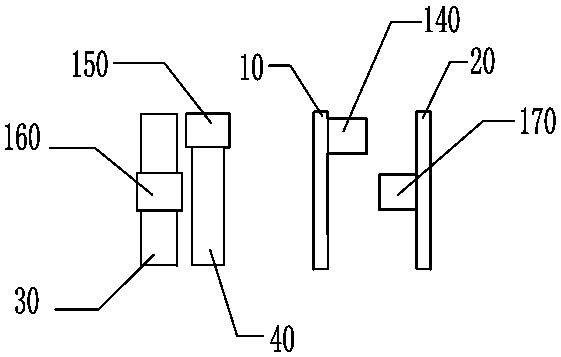

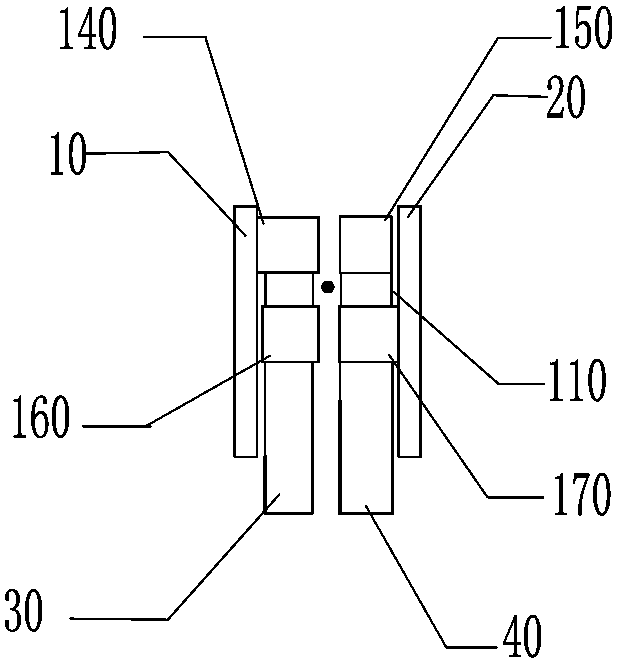

[0025] The first output electrode 30 is provided with a third terminal 160 (which can be connected by screws, the same below), and the second output electrode 40 is provided with a second terminal 150, (such as figure 2 shown on the left).

[0026] The first terminal 140 is installed on the first output electrode 30 through the insulating plate 110, the fourth terminal 170 is installed on the second output electrode 40 through the insulating plate 110, the first term...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com