Efficient binding type wire binding machine

A wire binding machine, high-efficiency technology, applied in the field of high-efficiency binding type wire binding machine, can solve the problems of low efficiency, wire winding, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

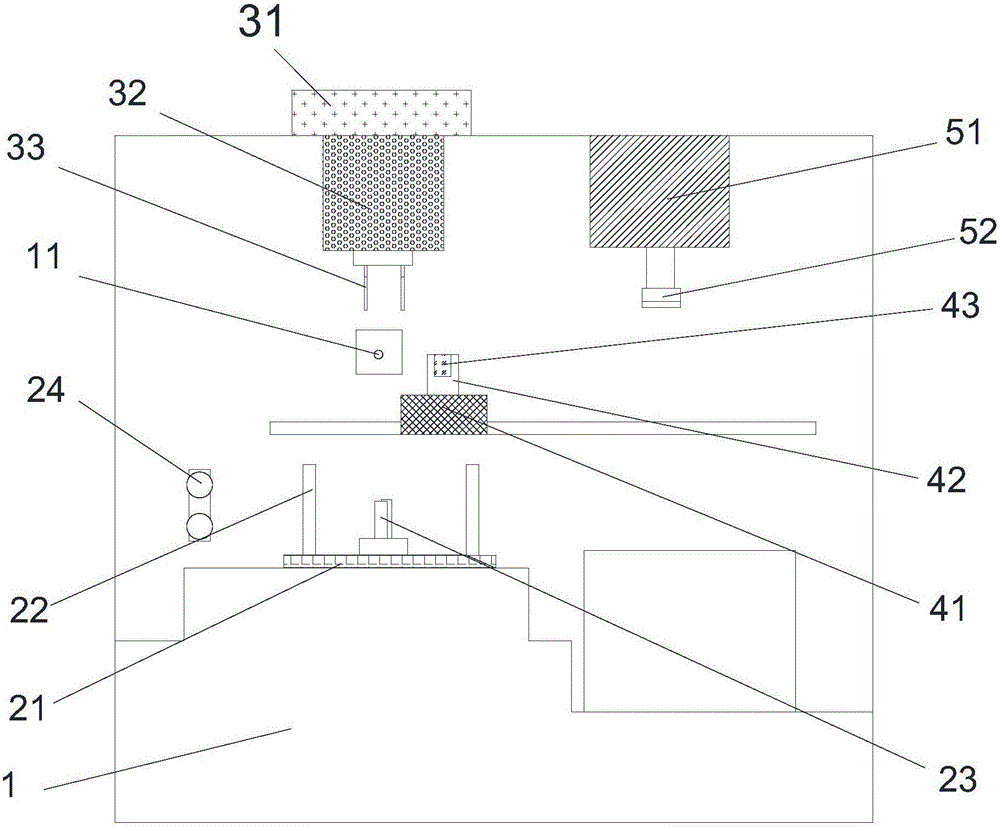

[0019] refer to figure 1 As shown, a high-efficiency bundling type wire tying machine proposed by the present invention includes a frame 1, a wire winding mechanism, a wire feeding mechanism, a winding mechanism and a wire tying mechanism;

[0020] The winding mechanism includes a rotating disc 21, two positioning posts 22, two first clamping claws 23 and two clamping rods 24. The rotating disc 21 can be movably installed on the frame 1, and the axial direction of the rotating disc 21 In the vertical direction, the two positioning columns 22 are vertically installed on the rotating plate 21, the two first clamping claws 23 are movably installed on the rotating plate 21, and the moving directions of the two first clamping claws 23 are close to each other and In the direction away from each other, the two clamping rods 24 are movably installed on the rack 1 corresponding to the position of the rotating disk 21, and the moving direction of the two clamping rods 24 is the directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com