Mixed bacterium for efficiently degrading atrazine and fermental culture method

A technique of atrazine, fermentation culture, applied in microorganism-based methods, biochemical equipment and methods, bacteria, etc.

Active Publication Date: 2016-07-27

山东鲁虹智慧农业研究院

View PDF12 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The research on the degradation of atrazine by using microbial preparations has made some progress, but most of the

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

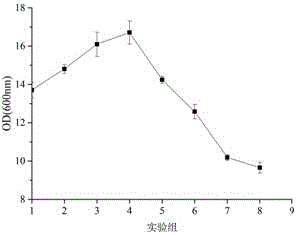

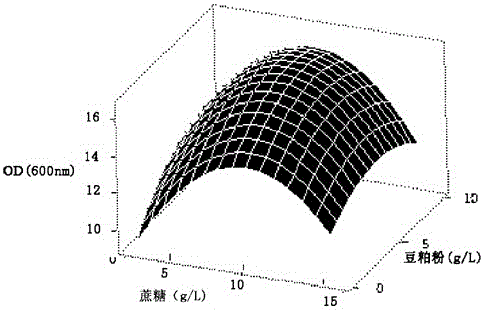

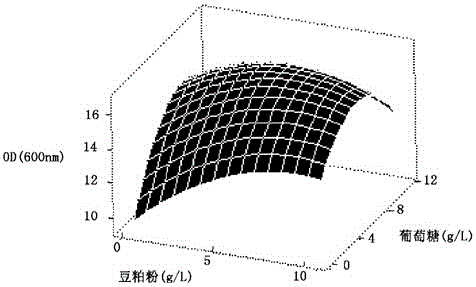

The invention relates to burkholderia caribensis and comamonas for efficiently degrading atrazine. A mixed fermental culture medium formula and a culture method for high-density cell culture are obtained through response surface optimization design, and specially, a mixed bacterium for efficiently degrading atrazine and a fermental culture method are provided. According to the mixed bacterium, the burkholderia caribensis and the comamonas for efficiently degrading atrazine are utilized; a formula of a fermental culture medium for high-density cell culture is obtained through response surface optimization design; the formula comprises 6.72g of cane sugar, 6.75g of glucose, 6.34g of bean pulp, 0.6g of dipotassium phosphate, 2.5g of monopotassium phosphate, 0.3g of magnesium sulfate heptahydrate, 0.4g of sodium chloride, 3g of yeast powder and 1L of distilled water; the pH is 7.0-7.5. The cultured mixed bacterial liquid is adopted for soil remediation tests, and 200mg/L of atrazine can be completely degraded within 7 days. A high-density fermental culture formula and method are provided for development of the mixed bacteria.

Description

technical field [0001] The invention relates to Burkholderia and Comamonas bacteria capable of efficiently degrading atrazine, and obtains a mixed fermentation medium formula and a culture method for high-density cell culture through response surface optimization design, specifically a A mixed bacterium for efficiently degrading atrazine and a fermentation culture method for the mixed bacterium. Background technique [0002] Atrazine, also known as atrazine (atrazine, atrazine), is characterized by containing benzene ring, stable structure, low water solubility, small adsorption coefficient and long residual period. At present, due to long-term and extensive use, it has caused serious pollution to the environment. Therefore, it is of great significance to study the degradation of atrazine. [0003] In previous studies, it was found that there are a large number of microorganisms with strong adaptability in nature. They can completely mineralize or degrade various pesticide...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C12N1/20C12R1/01

Inventor 黄道跟张娟杨春玉高超

Owner 山东鲁虹智慧农业研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com