Label sewing device

A label and supply device technology, applied in sewing equipment, sewing machine components, textiles and papermaking, etc., can solve the problems of large-scale, increased manufacturing cost, label maintenance, environmental impact, etc., to reduce the number of parts, prevent bending, improve rigid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

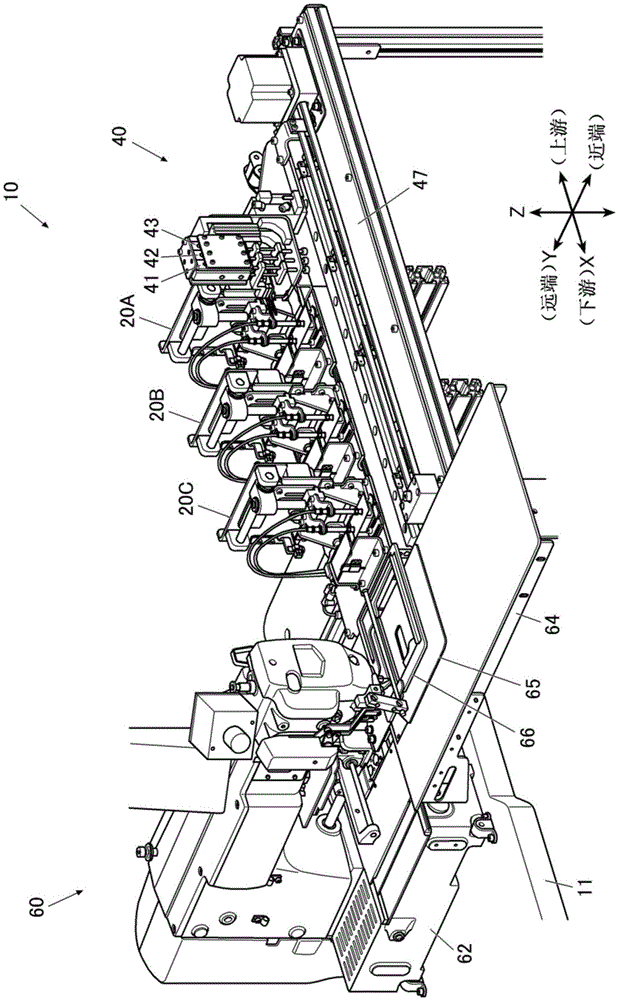

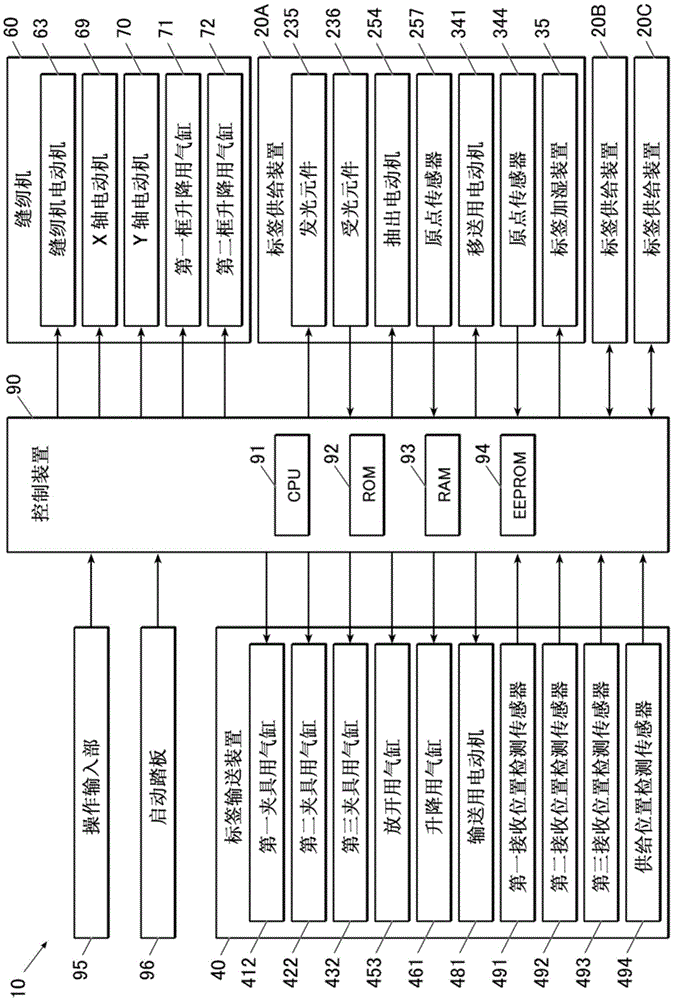

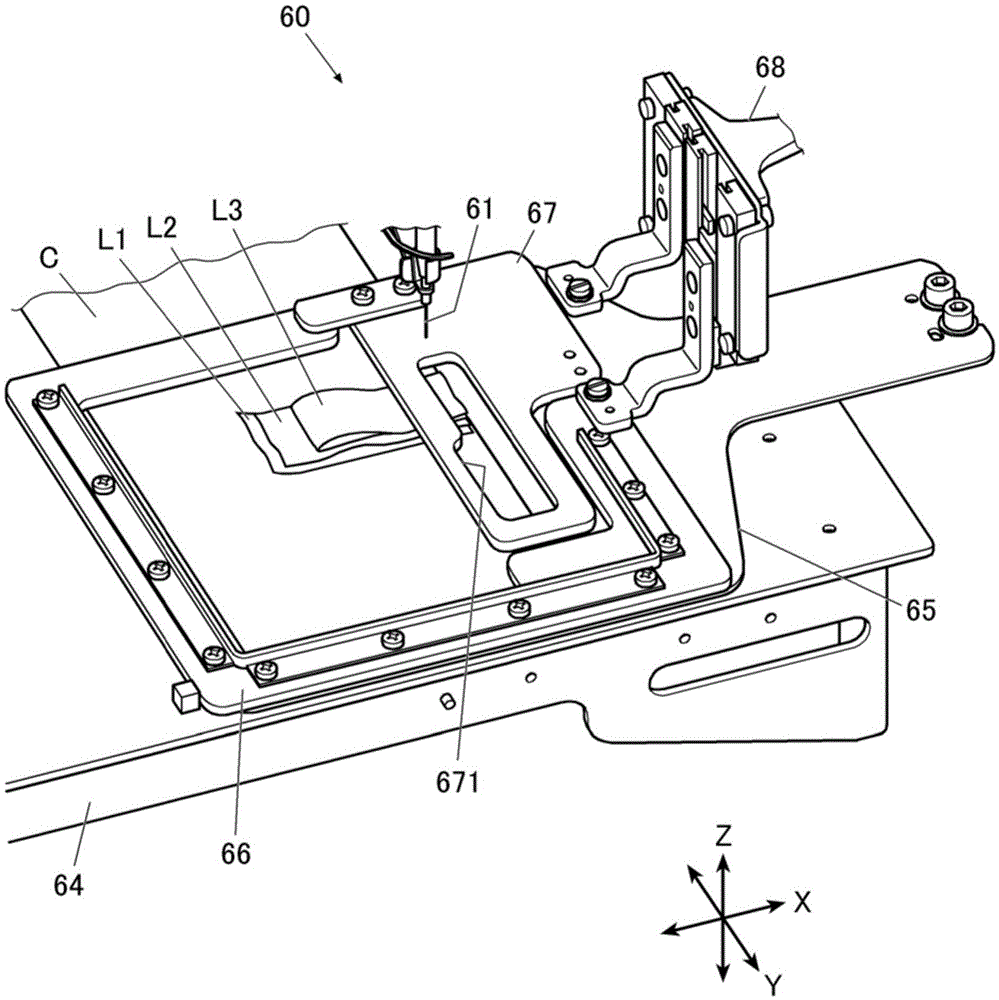

[0127] [Outline of Label Sewing Device]

[0128] Next, the label sewing device 10 of the present invention will be described with reference to the drawings. figure 1 is a perspective view of the label sewing device 10, figure 2 It is a control block diagram showing the control structure of the label sewing device 10 . As shown in the figure, the label sewing device 10 includes: three label supply devices 20A, 20B, and 20C that supply labels L1, L2, and L3 to be sewn to the cloth C of the sewn product; The labels L1, L2, and L3 supplied from the label supplying devices 20A, 20B, and 20C are conveyed; the sewing machine 60 sews the labels L1, L2, and L3 conveyed by the label conveying device 40 to the cloth C; The entire sewing device 10 is collectively controlled; and the workbench 11 places and supports the entire structure.

[0129] In addition, in the following description, the horizontal direction in which the label L is transported is referred to as the X-axis directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com