Near-edge guard railing for building and mounting method of near-edge guard railing

An installation method and construction technology, which can be used in construction, building structure, construction material processing, etc., can solve problems such as low cost, achieve low cost, reduce the probability of falling accidents, and reduce the risk of lack of protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

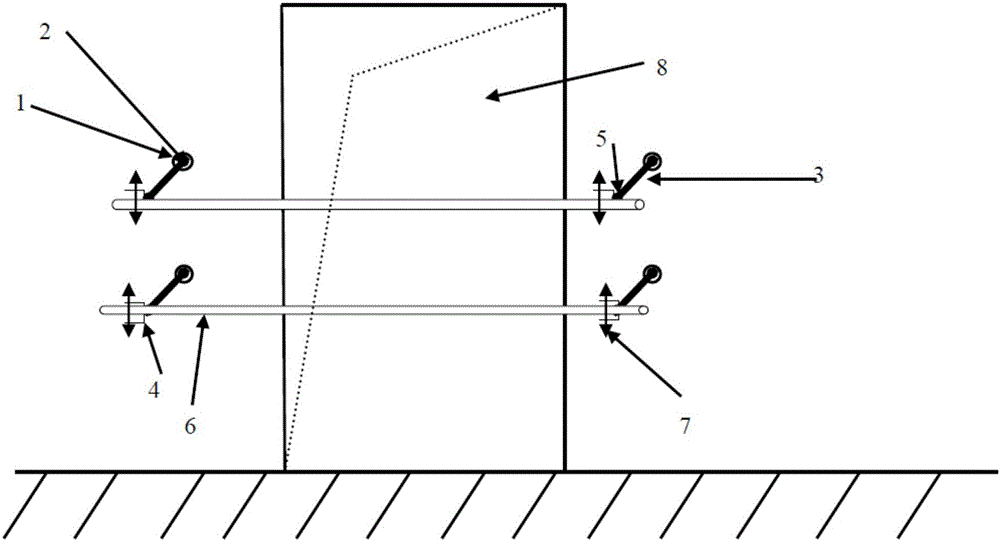

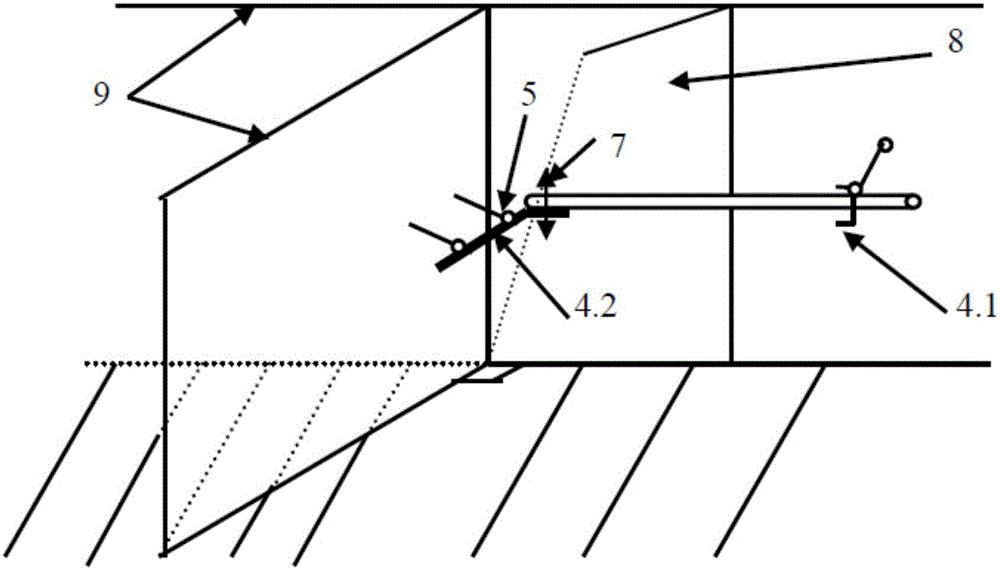

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0031] refer to Figure 1~Figure 5 As shown, the building border guardrail of the present invention includes cross bar 6, steel sheet fixing screw 5, prefabricated steel sheet 4, bolt rod 3, screw-in type expansion tube 2 and hole 1, and hole 1 is punched and is set at building near On the concrete wall or pillar next to the side hole 8, the screw-in expansion tube 2 is put into the hole 1, the bolt rod 3 is screwed into the screw-in type expansion tube 2, the prefabricated steel sheet 4 is set on the bolt rod 3, and the prefabricated steel sheet The sheet 4 is fixed on the bolt rod 3 by the steel sheet fixing screw 5, and the two ends of the cross bar 6 are fixed on the prefabricated steel sheet 4 by the cross bar bolt 7.

[0032] The hole 1 has a diameter of 10 mm and a depth of 50 mm, and the diameter of the screw-in expansion tube 2 is the same a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com