Nozzle-added type liquid bag making machine suitable for heat sealing of various film materials

A film material and bag making machine technology, used in bag making operations, container manufacturing machinery, flexible container manufacturing, etc., can solve problems such as easy breakage, inability to heat and seal edges, etc. The effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

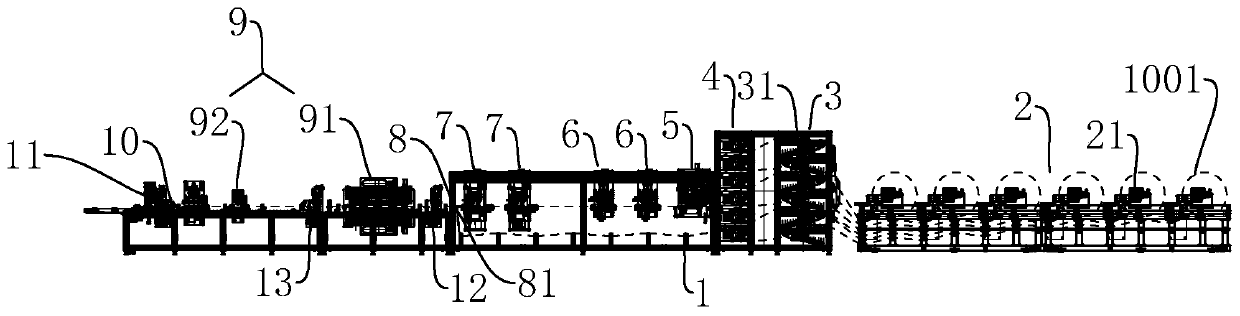

[0039] combine Figure 1 to Figure 7 The spout type liquid bag making machine suitable for heat sealing of various film materials of the present invention will be further described.

[0040] A nozzle-filling liquid bag making machine suitable for heat sealing of various film materials is characterized in that it includes a main frame 1 and a

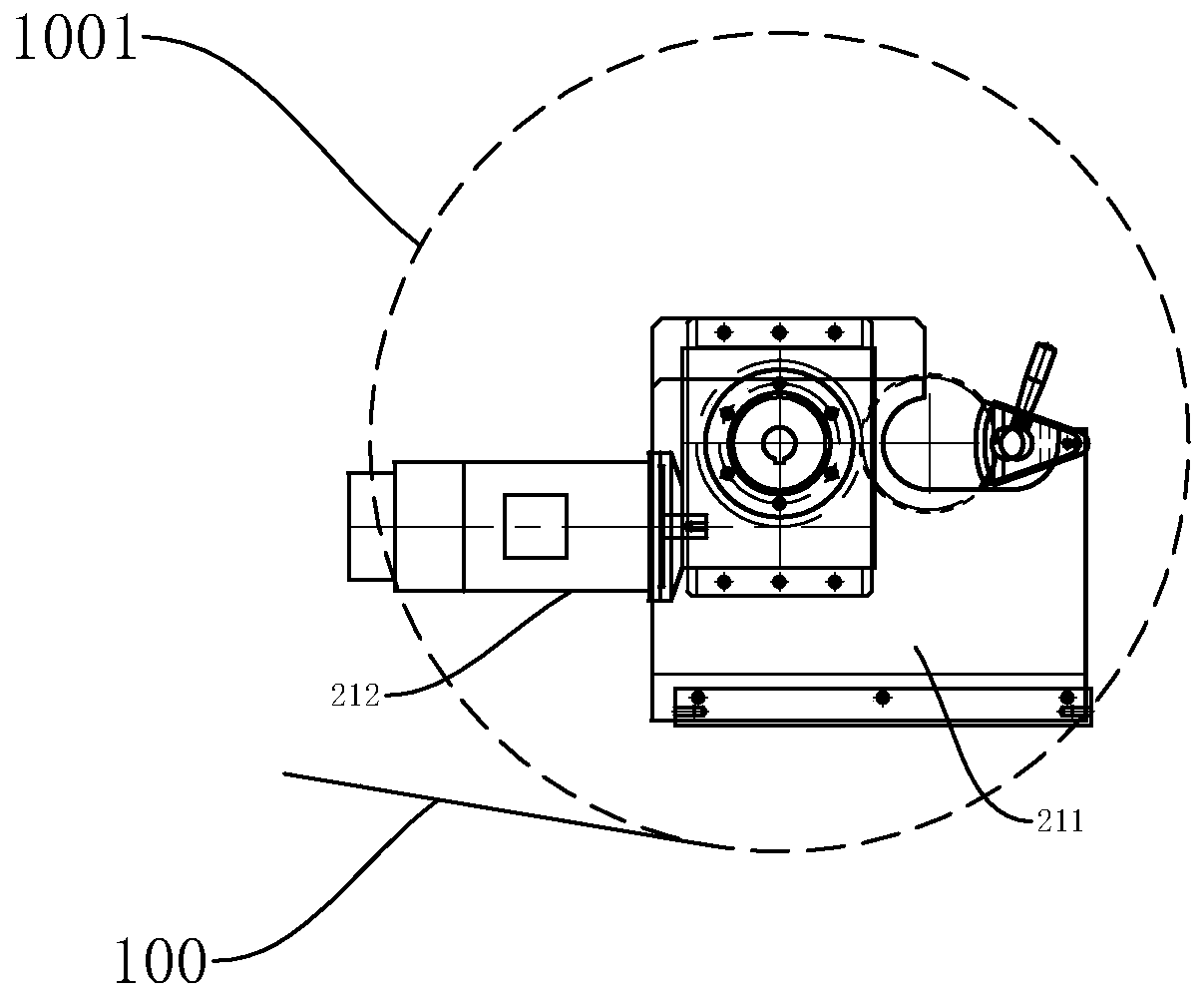

[0041] The feeding device 2 includes a plurality of raw material frame mechanisms 21 for erecting and discharging raw material rolls 1001. In this embodiment, there are six raw material frame mechanisms 21, that is, up to six rolls of film materials can be discharged at the same time, and can be used in actual use. Set the quantity according to the demand;

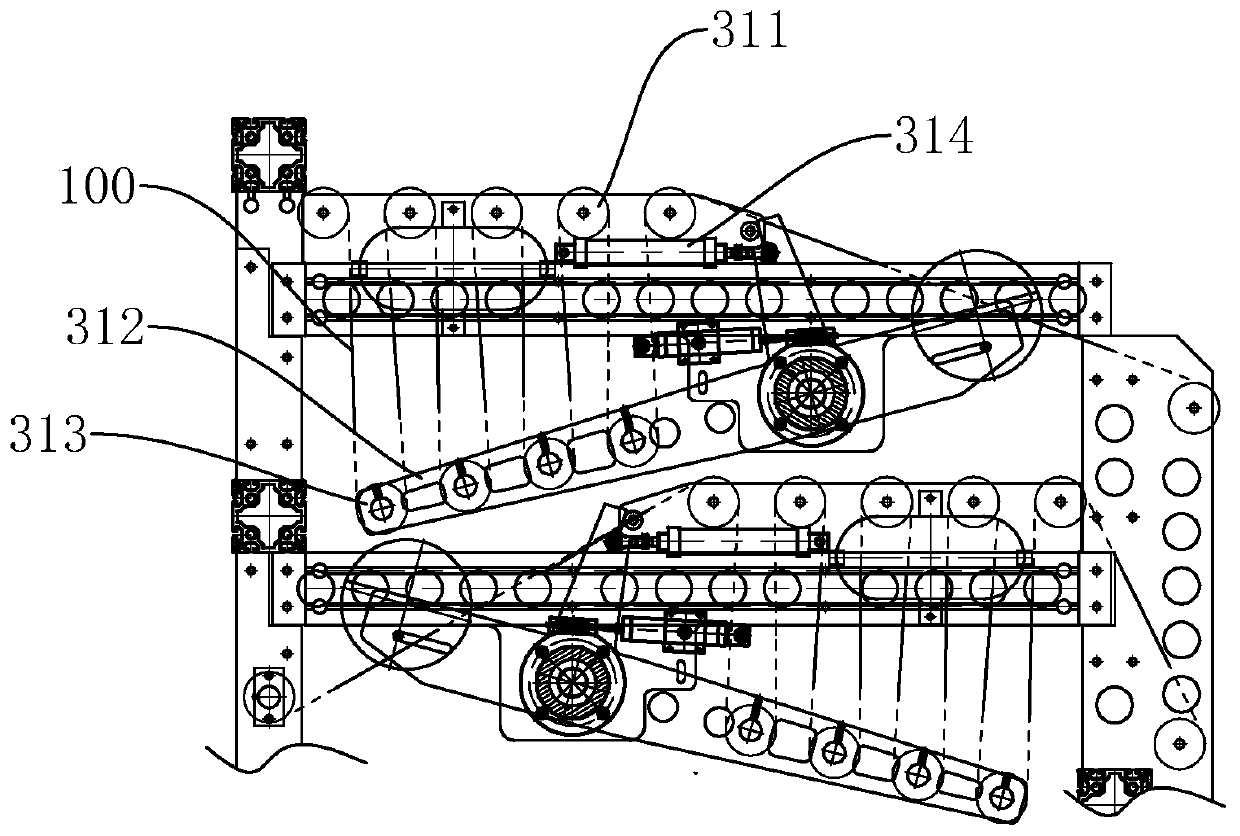

[0042] The adjustment device 3 includes a plurality of adjustment arm mechanisms 31 for receiving the raw materials of the feeding device 2 and adjusting the tension of the raw materials. In this embodiment, there are six adjustment arm mechanisms 31 arranged up and down to correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com