A kind of waterproof rubber powder composition and preparation method thereof

A composition and technology of waterproof glue, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of poor anti-aging ability, polluted environment, poor deformability, etc., and achieve strong adhesion, excellent corrosion resistance, Easy construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation of waterproof rubber powder for roofing requires impermeability, waterproof, crack resistance, compression resistance, and excellent performance. The mixing ratio of its waterproof rubber powder is (calculated by weight percentage): 35% of aluminosilicate, 17.65% of hydrated silicate, 15% of silicon dioxide; 10% of calcium powder; 10% of mineral powder; 10% of rubber powder; 0.8% plasticizer; 0.3% thickener; 1.0% silicone; 0.1% coagulant; 0.15% anti-cracking agent.

Embodiment 2

[0043] Embodiment 2 (taking 1000kg as example)

[0044] Add 350kg of aluminosilicate, 250kg of hydrated magnesium silicate, 100kg of silicon powder, 50kg of calcium powder, and 100kg of primary coal ash into a 1000L mixer, start the mixer, and stir for ten minutes.

[0045] In the stirrer (device) of 500L, add ethylene and vinyl chloride and ethyl laurate terpolymer rubber powder 95kg, add sodium polycarboxylate plasticizer 10kg, hydroxyethyl methylcellulose 4kg in the process of stirring, Siloxane 20kg, calcium formate 20kg, polypropylene fiber 1kg, stir for 20 minutes after the addition is complete, make it fully stirred and then stop the machine, input the mixture into a 1000L mixer and mix with the silicon composite material for 15 minutes, no aggregates and no After agglomeration and uniform dispersion, measure and pack as waterproof rubber powder composition 1000KG, model SJ601A.

Embodiment 3

[0046] Embodiment 3 (taking 1000kg as example)

[0047] With a 1000L mixer, add 350kg of high-performance silicate powder, 200kg of calcium silicate, 200kg of silicon dioxide, and 50kg of first-grade coal powder while stirring. After stirring for 10 minutes, add 2kg of anti-cracking agent fiber, hydroxyl Ethyl cellulose 5kg, sulfamate 15kg, silane 30kg, sodium thiosulfate 30kg, vinyl acetate and ethylene copolymer binary rubber powder 118kg, continue to stir for 20 minutes after the addition is complete, make it fully mixed and then measure The packaging is waterproof rubber powder 1000KG, and it is model SJ601B.

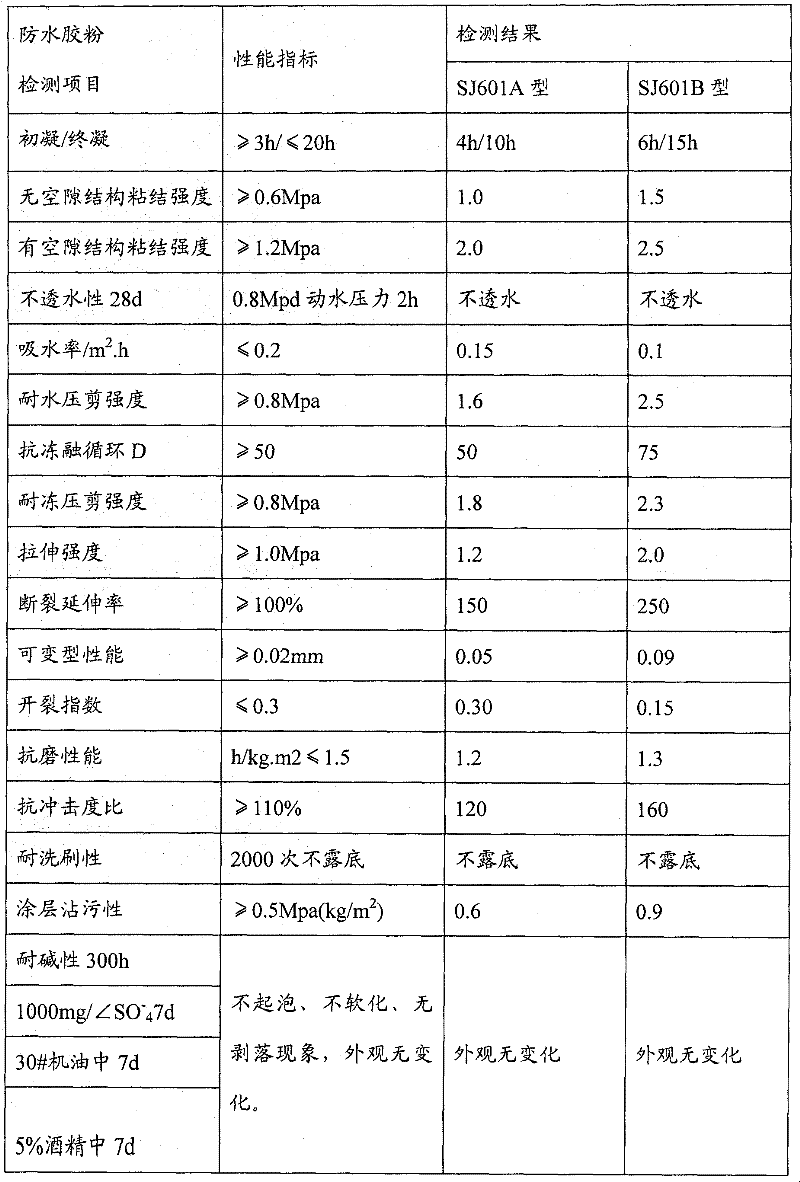

[0048] The performance index of waterproof, anti-corrosion and anti-cracking using the waterproof rubber powder of the present invention is illustrated by the test in Table 1, and the test reference standard is JC / T894-2001, JC474-1999.

[0049]

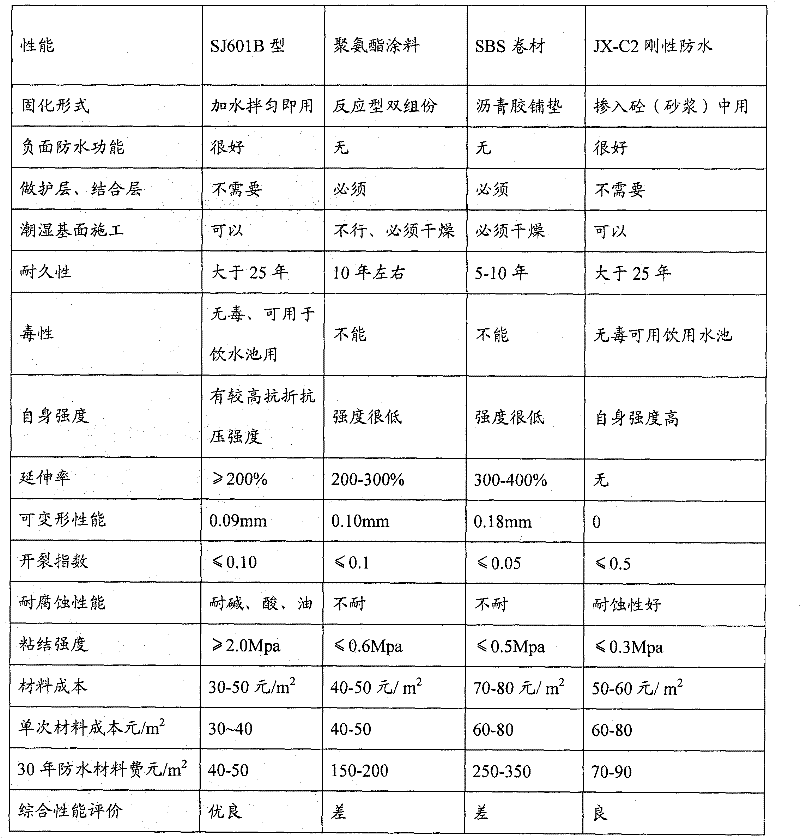

[0050] Table 2 is the performance and benefit comparison of the waterproof rubber powder of the present invention an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com