Air preheater sector plate circular arc section sealing device

An air preheater and sealing device technology, which is used in the sealing of engines, lighting and heating equipment, combustion methods, etc., can solve problems such as large leakage space, poor sealing effect, leakage, etc., so as to reduce flue gas leakage and improve the overall The effect of seal level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

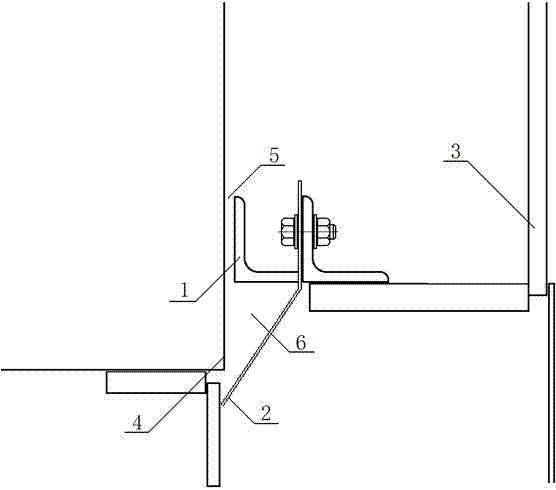

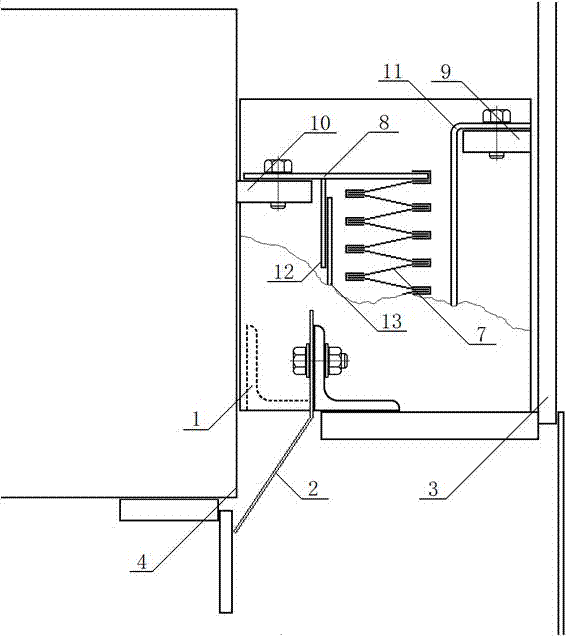

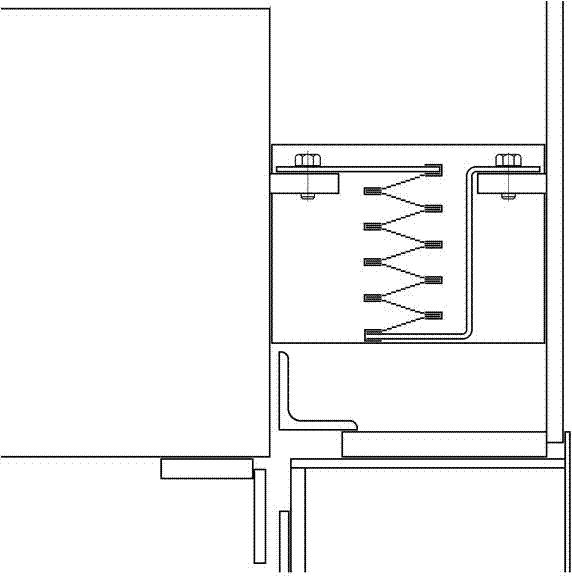

[0016] Such as figure 2 , 3 , 4, an air preheater sector plate arc section sealing device, including sector plate sealing angle steel 1 and bypass sealing sheet 2, one end of bypass sealing sheet 2 is fixedly connected to the hot end connecting ring 3 through a bracket On the other hand, the other end of the bypass sealing sheet 2 rests on the sealing surface 4 of the circular arc section of the fan-shaped plate through the elastic recovery force, and the hot-end lugs are respectively set on the hot-end connecting ring 3 and the sealing surface 4 of the circular arc section of the fan-shaped plate. Plate 9 and fan-shaped plate ear plate 10, a circle of bellows 7 is set outside the sealing surface 4 of the fan-shaped plate arc section, and one end of the bellows 7 is fixedly connected to the fan-shaped plate ear through a dynamic connection ring plate 8 On the plate 10 , the other end of the bellows 7 is fixedly connected to the hot end ear plate 9 through the static connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com