Backlight module and liquid crystal display device

A backlight module and backplane technology, applied in optics, nonlinear optics, instruments, etc., can solve the problem that the D value is too small, the liquid crystal panel and the upper surface of the middle frame arm are easily detached, and cannot meet the technical requirements of the liquid crystal panel. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

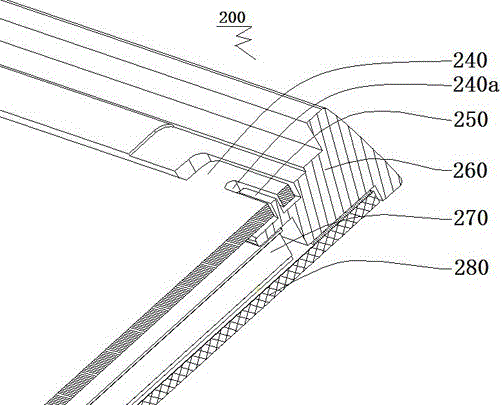

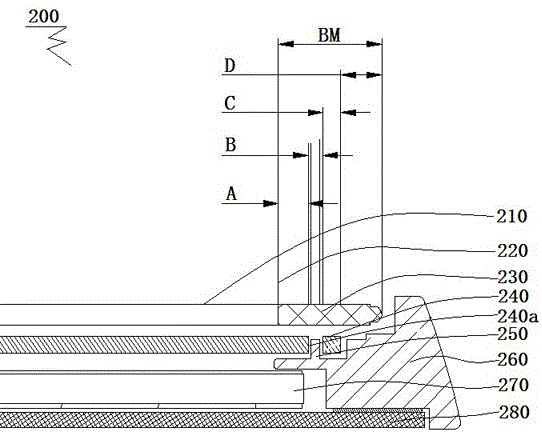

[0046] Such as Figure 2a~Figure 10 As shown, the backlight module liquid crystal display device provided by Embodiment 1 of the present invention will be described in detail below with reference to the accompanying drawings. The backlight module of the liquid crystal display device provided by the embodiment of the present invention not only includes Figure 2a~Figure 10 In addition to the structure shown, it also includes at least a backlight source, a reflector, etc. For other components of the backlight module of the liquid crystal display device in the embodiment of the present invention, those skilled in the art can refer to the backlight module of the liquid crystal display device disclosed in the prior art The specific structure is not limited in the present invention.

[0047] Figure 2a It is an overall view of the liquid crystal display device of the present invention; Figure 2b for Figure 2a Partial enlarged view of part A of ; Figure 2c for Figure 2b Par...

Embodiment 2

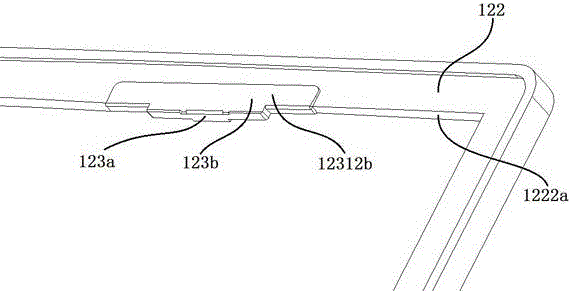

[0065] The second embodiment is a modified example of the first embodiment, combined with reference Figure 11 , Figure 12 and Figure 13 , different from Embodiment 1, the second part 123b of the bracket is a single flat plate 1231b, and the flat plate 1231b includes a top surface 12311b and a bottom surface 12312b; correspondingly, the lower surface of the middle frame 122 is a plane 12232a.

[0066] combined reference Figure 11 , Figure 14a and Figure 14b As shown, the second part 123b is fixedly connected to the plane 12232a on the lower surface of the middle frame through the top surface 12331b of the flat plate. The fixing method can be selected by sticking or screwing, and it can also be sandwiched. The present invention is not limited here. .

[0067] continue as Figure 11 As shown, the backboard 124 is fixedly connected to the bottom surface 12312b of the flat panel, and the fixing method can be pasted or fixed by screws, which is not limited in the present...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap