Powder recycling post-processing system

A powder and sealed cavity technology, applied in the field of powder recovery post-processing system, can solve the problems of powder not easily scattered and polluted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Some typical embodiments embodying the features and advantages of the present invention will be described in detail in the description in the following paragraphs. It should be understood that the present invention is capable of various changes in different aspects without departing from the scope of the present invention, and that the description and illustrations therein are illustrative in nature and not restrictive. this invention.

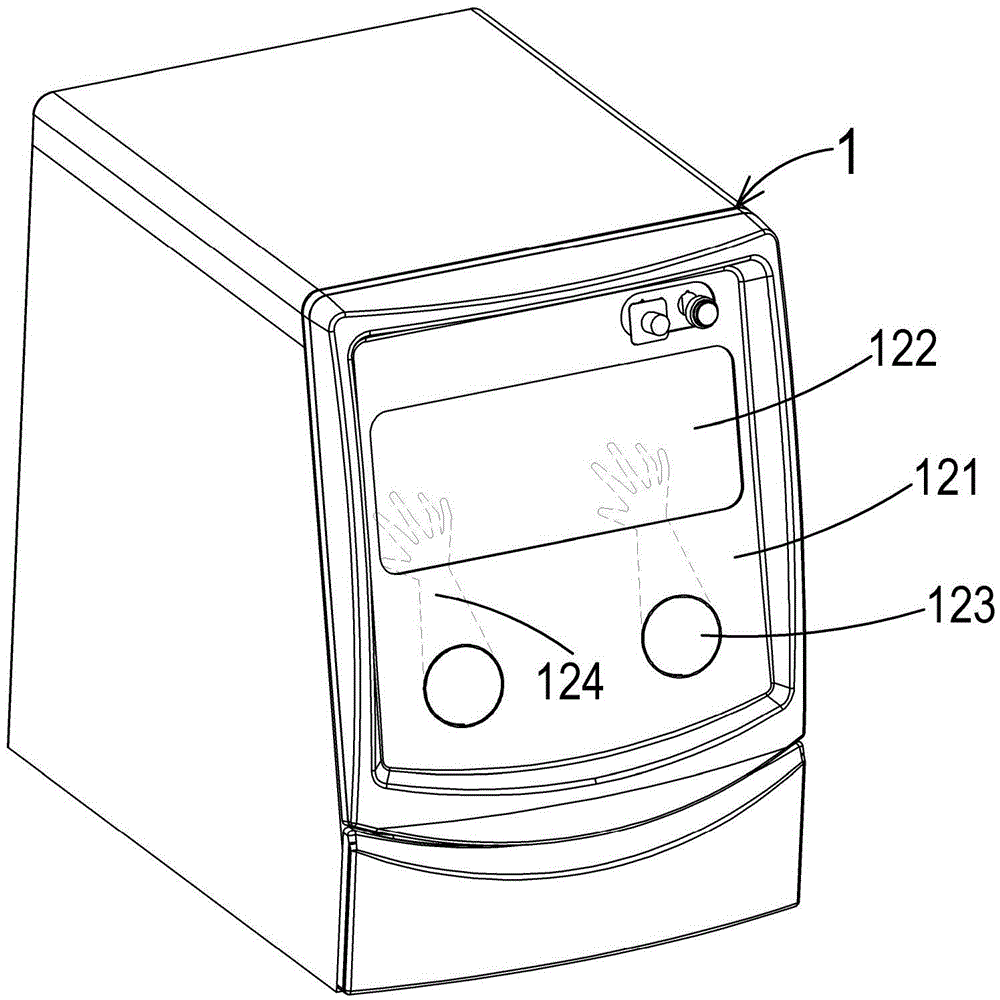

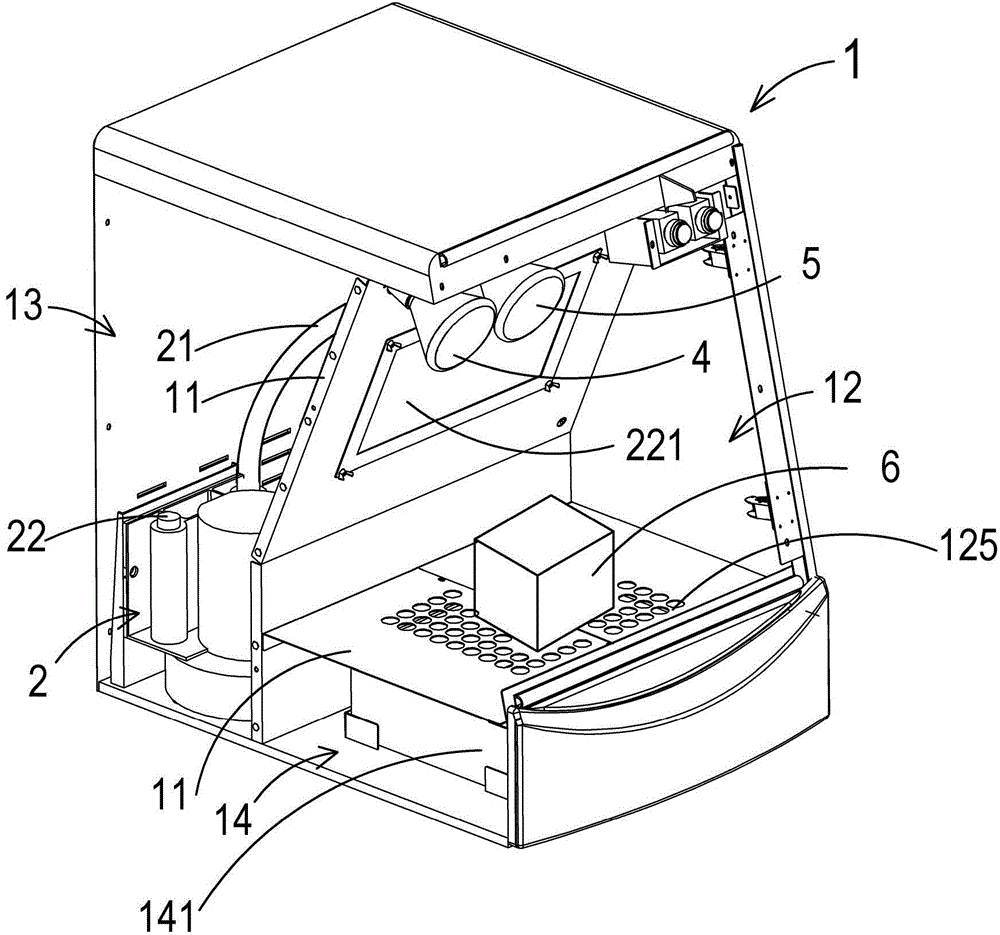

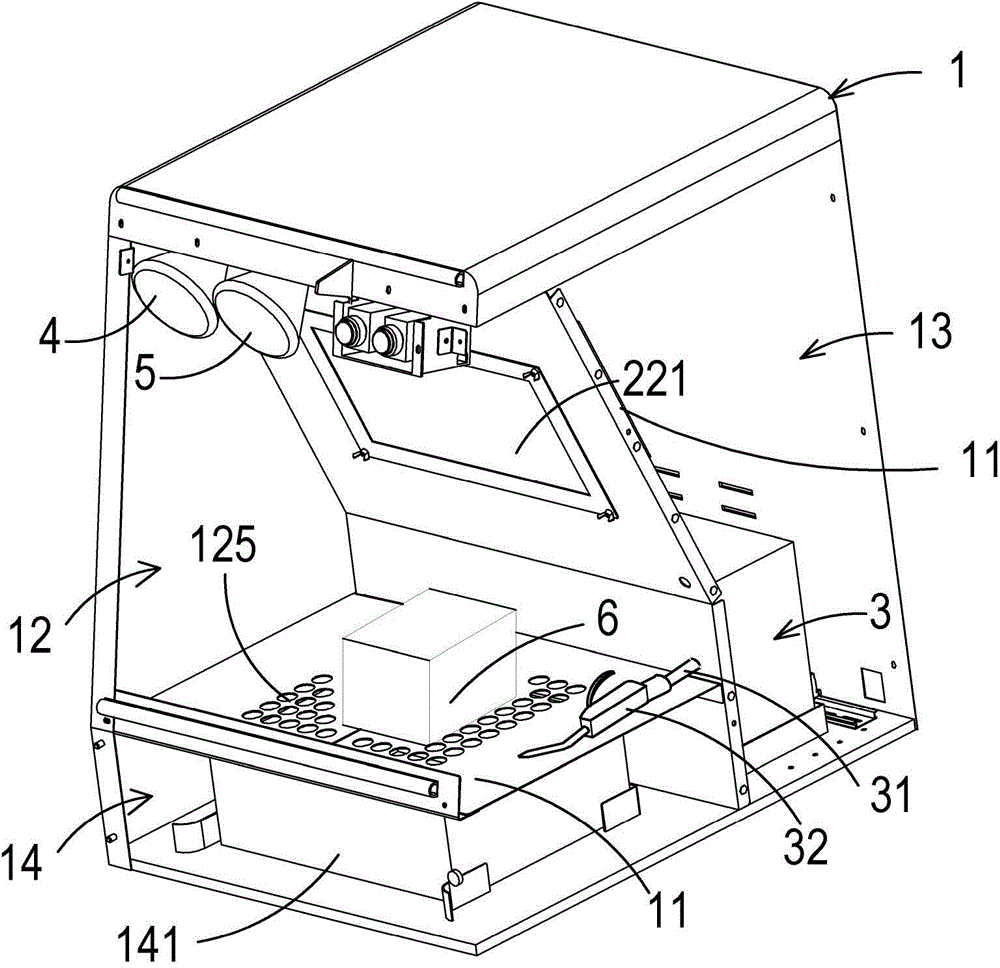

[0035] As shown in Figures 1 to 4, the powder recycling post-processing system of the present invention mainly includes a sealing body 1, a negative pressure device 2, an air pressure generating device 3, a lighting lamp 4 and a heating lamp 5.

[0036] The sealed body 1 has a sealed chamber 12 separated by a plurality of partitions 11, a device placement space 13 and a rest material placement space 14 are isolated from each other, and the sealed chamber 12 can accommodate the 3D molded object 6 for further processing Material powder r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com