Control device for four-wheel drive vehicle

一种四轮驱动、控制装置的技术,应用在控制装置、机动车、混合动力车辆等方向,能够解决驱动损失增大、发动机耗油量变大等问题,达到抑制异音、抑制耗油量变大的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

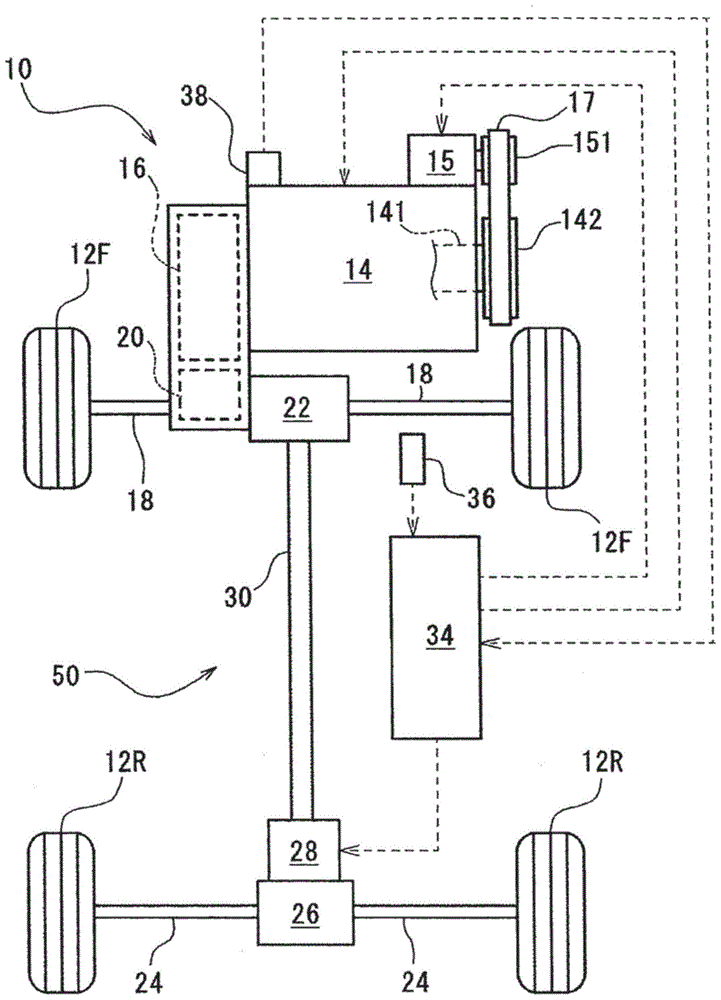

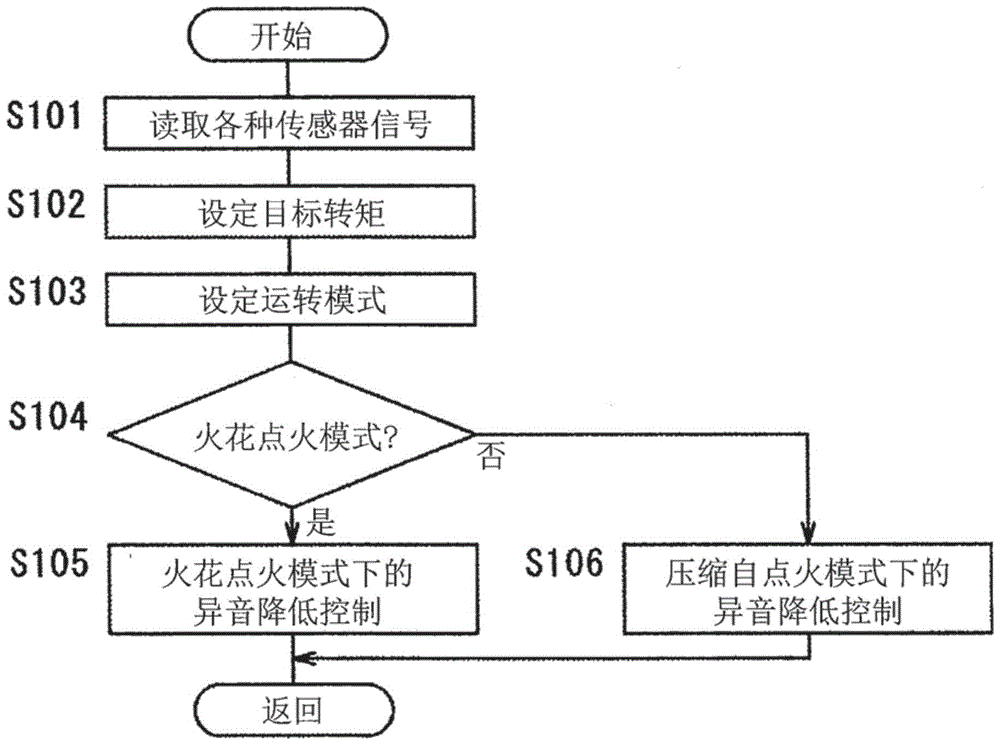

[0035] figure 1 It is a schematic configuration diagram showing a four-wheel drive vehicle 10 to which the control device according to the present invention is applied. The four-wheel drive vehicle 10 has: an engine 14; a transmission 16 that decelerates the output torque of the engine 14 at a predetermined reduction ratio; and transmits the output torque decelerated by the transmission 16 to left and right front wheels 12F (main drive wheels) ) differential device 20 for the front wheels; a transfer case 22 that takes out the output torque transmitted to the left and right rear wheels 12R (auxiliary drive wheels) from the differential device 20 for the front wheels; and transfers the output torque from the transfer case 22 The moment is transmitted to the rear wheel differential device 26 of the left and right rear wheels 12R via the axle shaft 24 .

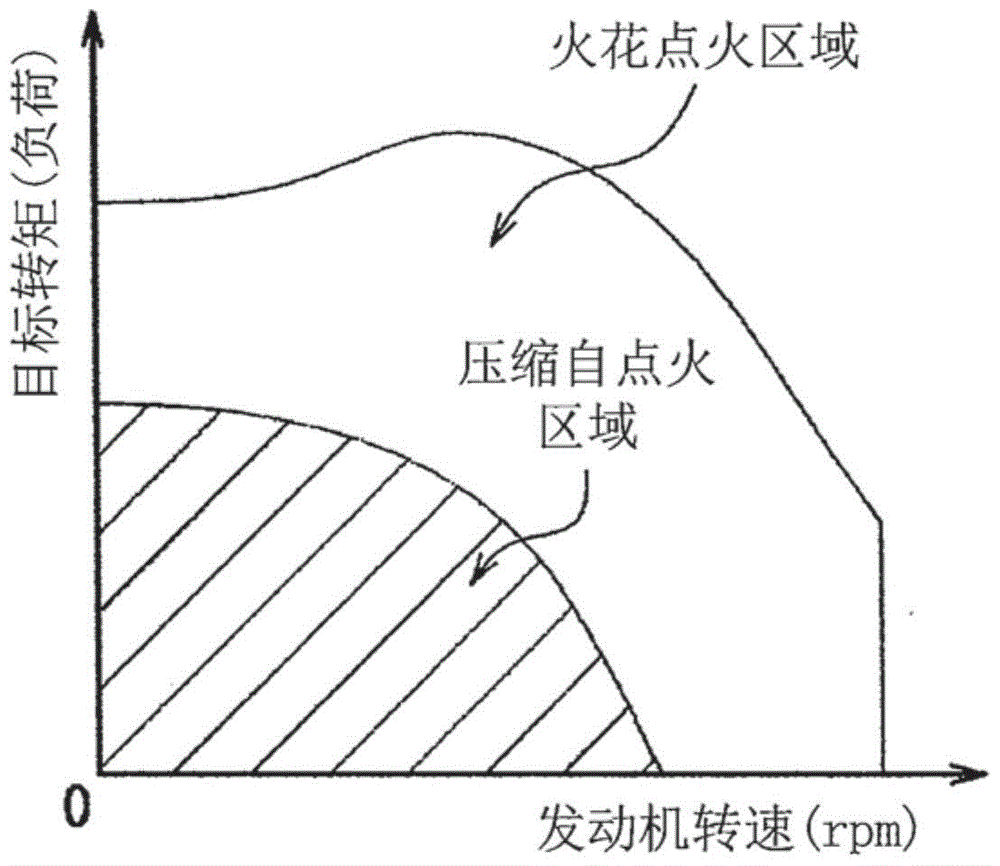

[0036] The engine 14 is a multi-cylinder engine having a plurality of cylinders, for example, an in-line four-cylinder engine...

no. 2 approach

[0113] refer to figure 1 , although description is omitted in the first embodiment, the four-wheel drive vehicle 10 includes a drive motor 15 that assists the engine 14 with torque. In the first embodiment, as an example in which the control device 34 (abnormal noise reduction unit) adjusts the torque distribution to the rear wheels 12R according to the magnitude of the fluctuating torque of the engine 14, a response to the spark ignition mode and the compression automatic An example of a change in fluctuating torque during a mode change between ignition modes. In this second embodiment, an example is given in which the control device 34 responds to changes in fluctuating torque to the extent that the torque assist by the drive motor 15 is accompanied.

[0114] Such as figure 1 As shown, a drive pulley 151 is attached to the output shaft of the drive motor 15 , and a crank pulley 142 is attached to the crankshaft 141 of the engine 14 . A winding transmission member 17 is wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com