Movable type dust removing system of bulk cement and sacked cement car loader

A technology of dust removal system and vehicle loading machine, which is applied in the directions of transportation, packaging, loading/unloading, etc. It can solve problems such as difficulty, inconvenient movement, and harsh working environment, and achieve the goal of increasing the internal space and improving the dust collection effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

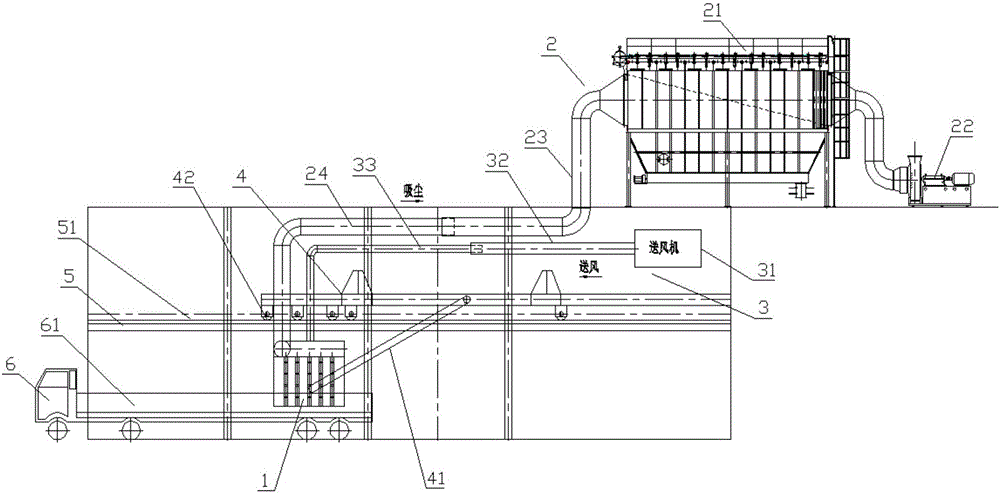

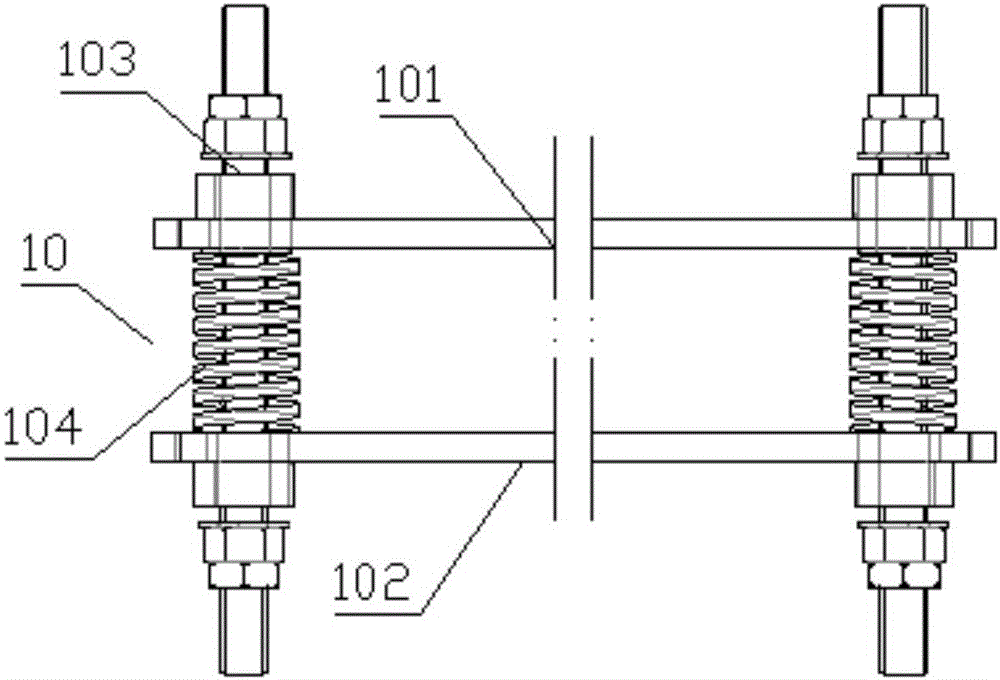

[0020] Such as figure 1 As shown, the dust removal system of the mobile bulk bagged cement loading machine includes a dust collection cover 1 and a dust collection device 2 and an air supply device 3 connected to the dust collection cover 1 . The car loading machine loads the bagged cement in the rear compartment 61 of the cement transport vehicle 6, and the dust collection cover 1 is arranged correspondingly to the car loading machine.

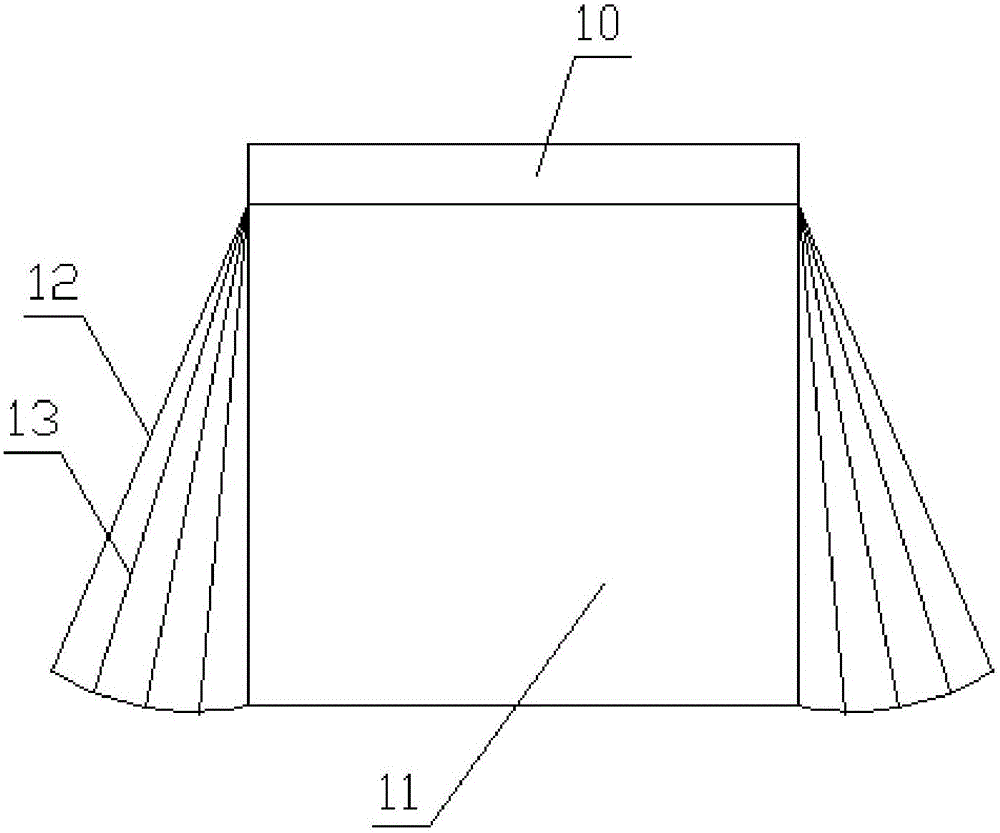

[0021] The present mobile bulk bagged cement loading machine generally comprises a mobile support 4, a conveyor belt 41 connected to the mobile support 4, the conveyor belt is arranged obliquely, and the feeding port below the conveyor belt faces the rear compartment 61 of the cement transport vehicle 6, And the dust collection cover 1 cover is located at the top of the feeding port, and in the loading process, the air blower 3 blows air in the dust collection cover 1, and the dust collection device 2 sucks the cement dust in the dust collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com