Industrial reducer and shifting method of industrial reducer

A reducer, industrial technology, applied in the direction of elements with teeth, gear transmission, belt/chain/gear, etc., can solve the problem of high investment cost and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

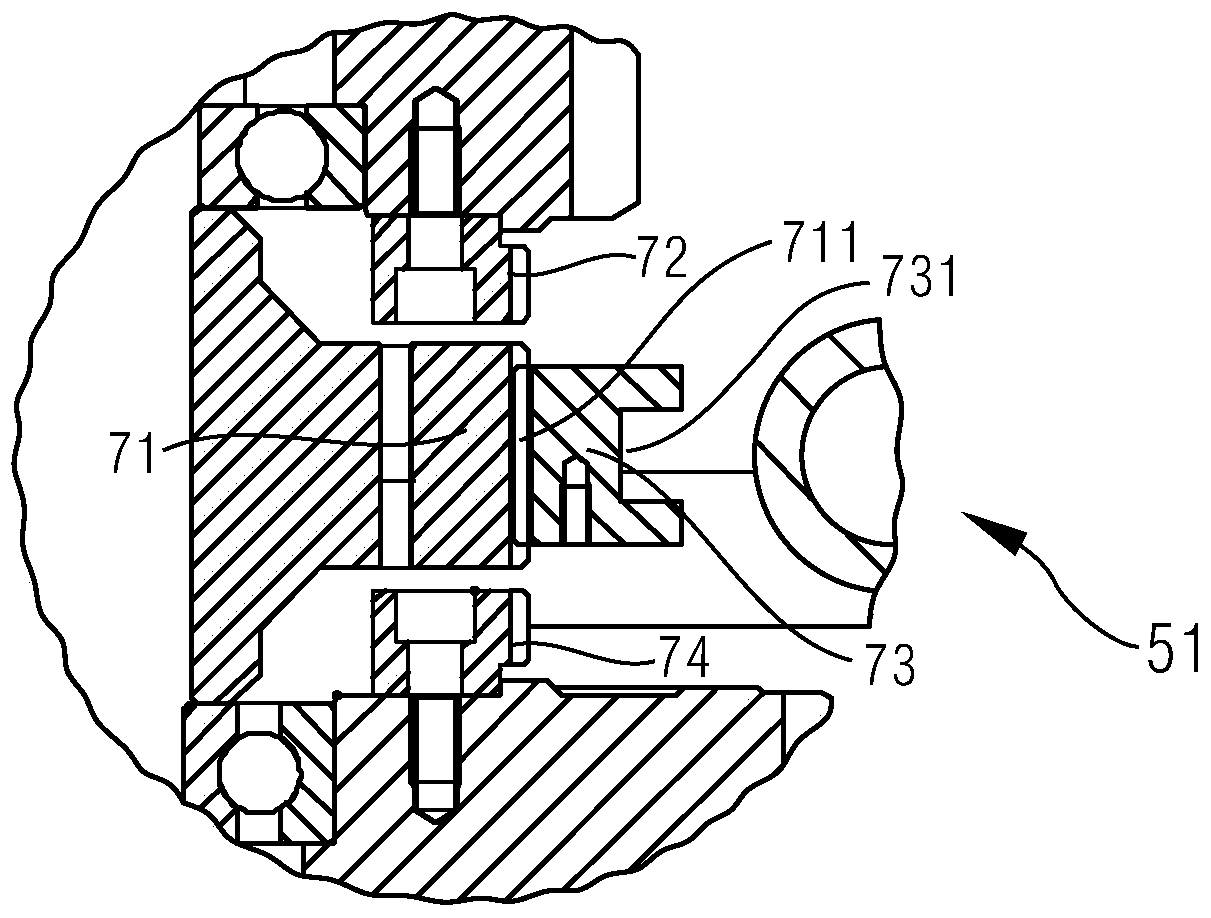

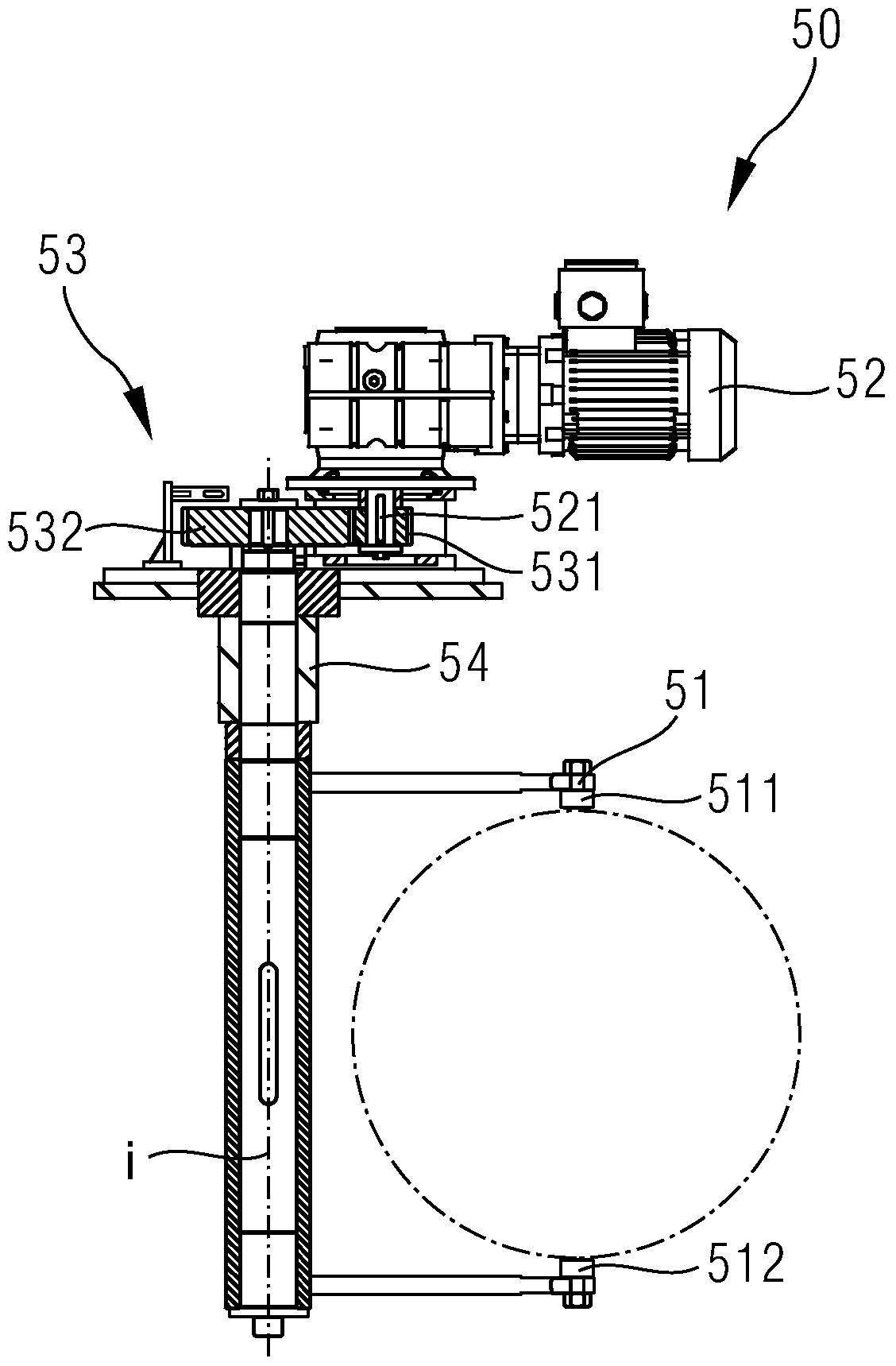

[0082] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0083] figure 1 An industrial reducer according to an embodiment of the present invention is schematically shown. The speed reducer includes a housing 10 , and an input shaft 20 is rotatably supported on the shaft hole of the housing 10 through a pair of bearings 21 , 23 . Bearings 21, 23 may be roller bearings. The input end 201 of the input shaft 20 is connected with a power source (not shown here). The input shaft 20 also includes a first pinion 22 , which is fixedly connected to the input shaft 20 , and a second pinion 24 , which is also fixedly connected to the input shaft 20 . The first pinion 22 and the second pinion 24 generally have different numbers of teeth.

[0084] In the housing 10, a pinion shaft 30 is also pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com