High-color-temperature LED lamp bead manufacture technology

A technology of LED lamp beads and production process, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of low luminous color temperature, lack of authenticity of scene colors, affecting visual experience, etc., to achieve rich visual experience and improve visual experience. , increase the effect of realism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

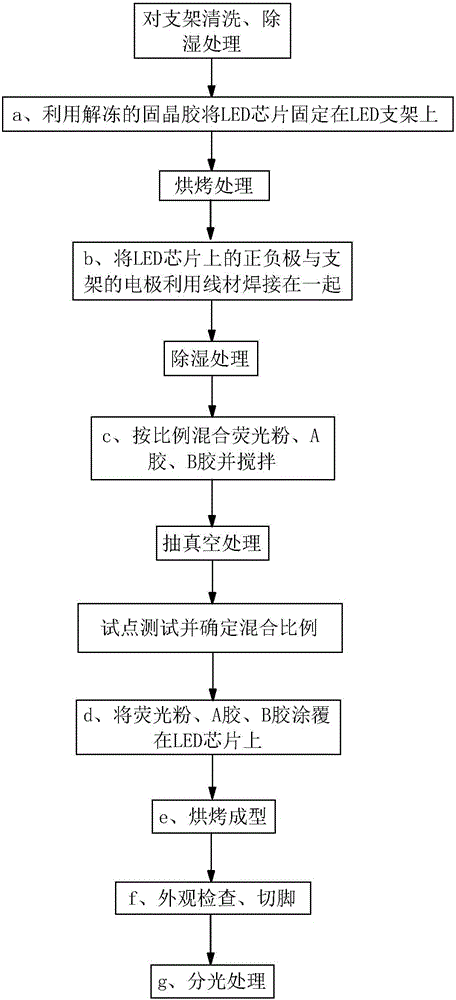

[0020] Such as figure 1 As shown, the manufacturing process of the LED lamp bead of the present invention includes the following steps: a. Fix the LED chip on the LED bracket by using a crystal-bonding glue and perform baking treatment; b. Use the positive and negative poles on the LED chip and the electrodes of the LED bracket to Weld the gold wires together; c. Mix and stir the fluorescent powder, glue A, and glue B in proportion; d. Fill and coat the mixed phosphor, glue A, and glue B on the LED bracket and cover the LED chip; e. Fill and coat The LED bracket with fluorescent powder, glue A and glue B is baked and formed.

[0021] The present invention includes the following improvements: the fluorescent powder includes yellow-green powder with a fluorescent wavelength range of 295-305nm, and green powder with a fluorescent wavelength range of 530-540nm. The fluorescent powder in this embodiment adopts yellow-green powder with a fluorescent wavelength range of 302nm, Green...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com