Quartz lamp heater flexible structure

A flexible structure and heater technology, applied in the direction of heating elements, ohmic resistance heating parts, etc., can solve the problems of lack of heating uniformity and structural versatility, and achieve the effect of shortening the test cycle, reducing test costs and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

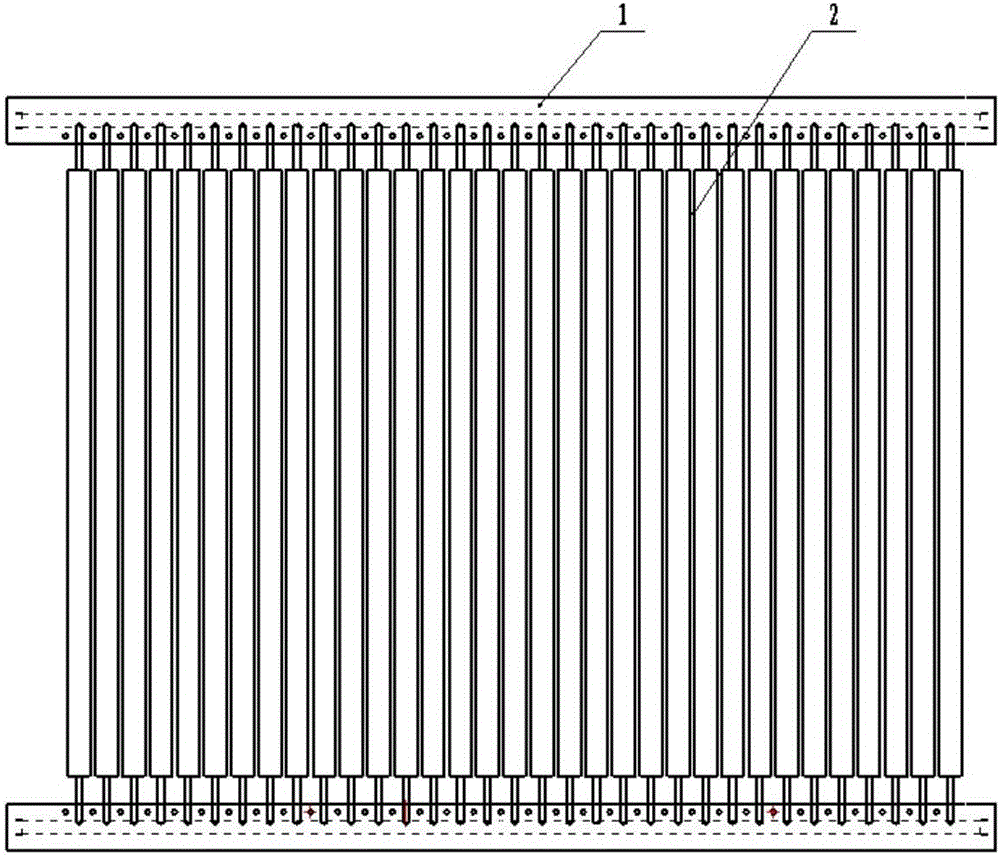

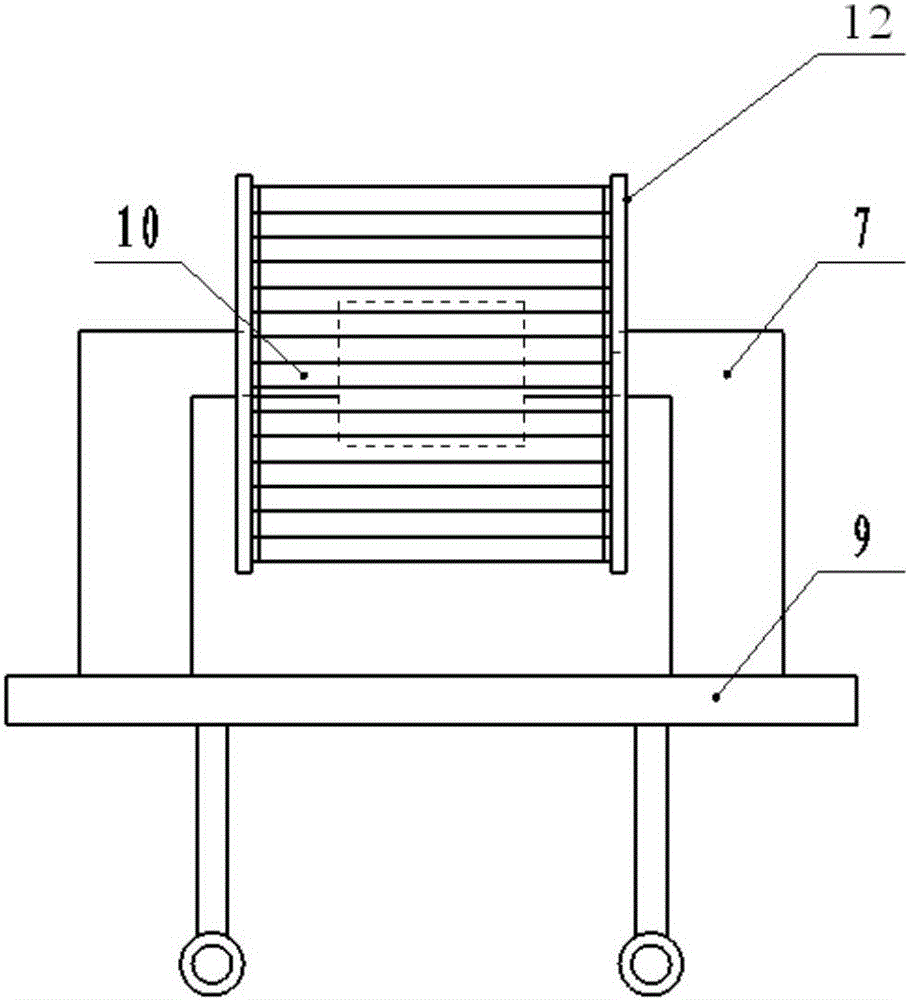

[0022] Such as image 3 , Figure 4 As shown, a flexible structure of a quartz lamp heater includes: a flexible connection tool 12, a movable clamp 15; the movable clamp 15 includes a fastener 16 and a chuck 17;

[0023] According to the size and shape of the test piece, bend the flexible connection tool 12 into a shape and size similar to that of the test piece, install several movable fixtures 15 in the chute 13 of the flexible connection tool 12, adjust the distance value, and use a tight Firmware 16 is fixed at equal intervals.

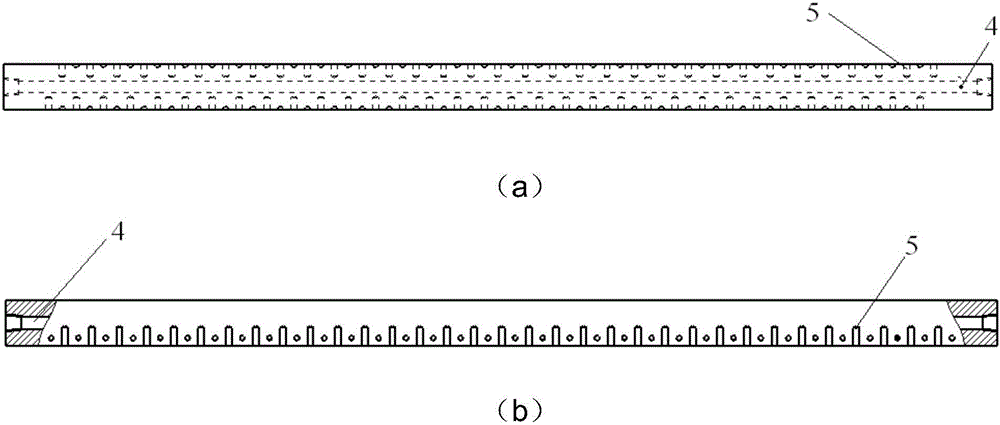

[0024] The structure of the flexible connection tooling 12 is as follows: Figure 5 As shown, the flexible connection tooling 12 is in the shape of a strip, and is made of stainless steel plates with a thickness of 0.002 to 0.005 m. Generally, the length is not greater than 1 m and the width is not greater than 0.03 m. Due to its thin thickness, the flexible connection tool 12 can have strong flexibility under the premise of a certain rigidity,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com