Frying-baking device with oil guiding function

A frying device and functional technology, applied in frying pans, household appliances, kitchen utensils, etc., can solve the problems of wasting electric energy, heat loss, and oil spills, etc., to reduce potential safety hazards, simple and compact structure, Easy to clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

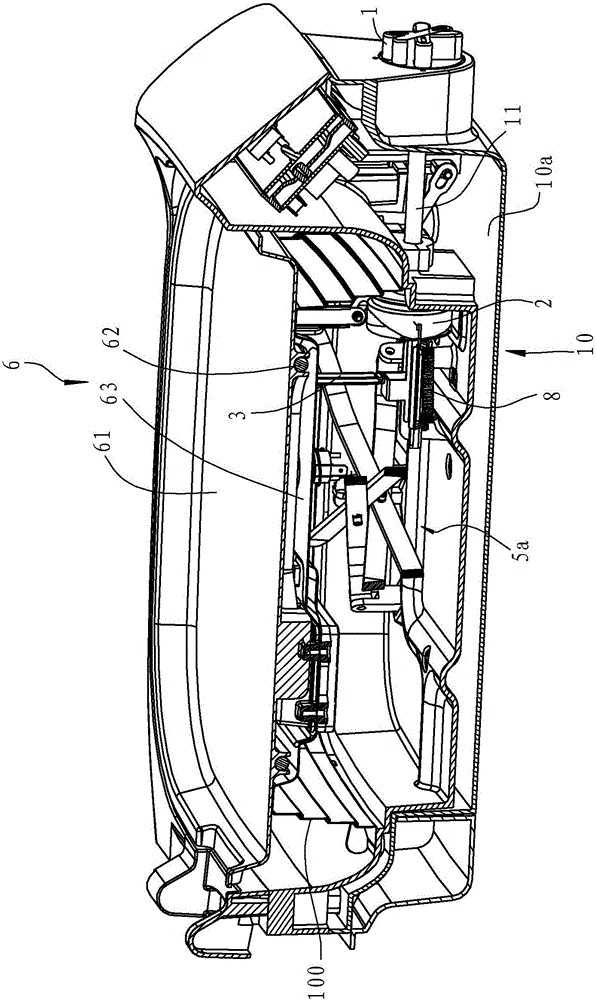

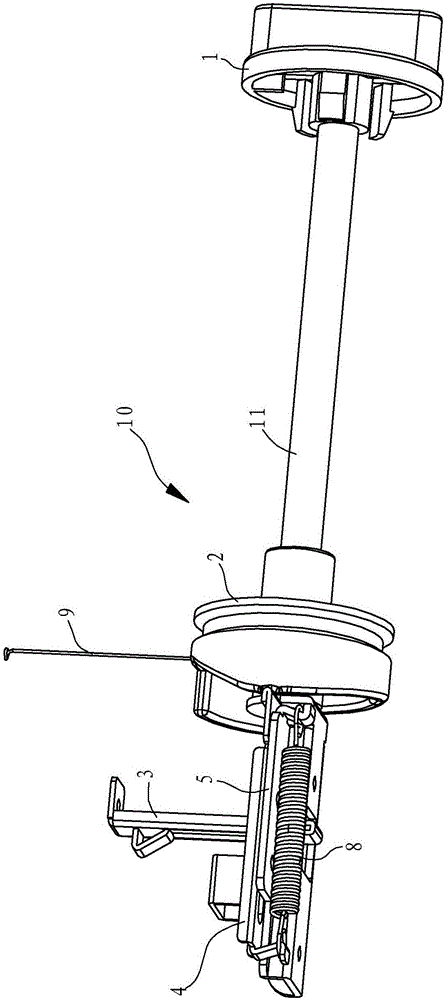

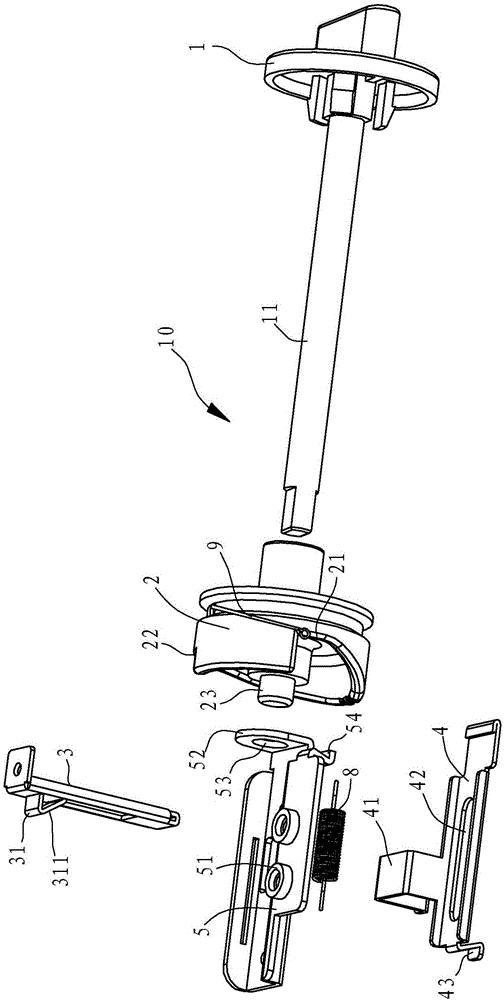

[0056] Example 1, such as figure 1 , Picture 9 with Picture 10 As shown, the grill pan can lift grill includes a lower shell 7, an upper shell 7c, an upper grill pan assembly 6c, a driving mechanism 10, a lifting mechanism 5a, a telescopic ring 100 and a lower grill set in the lower shell 7. As for the assembly 6, the driving mechanism 10 can drive the lower bakeware assembly 6 to achieve lifting, and the lifting mechanism 5a can be telescopic and is arranged between the lower shell 7 and the lower bakeware assembly 6. The lower bakeware assembly 6 includes a lower bakeware 61, a reflection plate 63 and a heating tube 62. The reflection plate 63 is disposed on the lower end surface of the lower bakeware 61, and the heating tube 62 is disposed in the space formed by the reflection plate 63 and the lower bakeware 61. The lower shell 7 is provided on the base 10a.

[0057] Combine Figure 7 with Figure 8 As shown, the upper end of the telescopic ring 100 is hermetically connected...

Embodiment 2

[0068] Example 2, such as Figure 13 with Figure 14 As shown, the lifting mechanism 5a in this embodiment includes an upper fixing piece 51a, a lower fixing piece 52a, a linear bearing 53a and a guide post 54a.

[0069] The upper fixing piece 51a has a square ring shape and is provided on the lower end surface of the reflecting plate 63. The lower fixing piece 52a is also a square ring shape and is provided on the upper end surface of the lower housing 7. There are four linear bearings 53a on the lower end surface. At the four corners of the fixing piece 52a, each linear bearing 53a has a longitudinal guide hole. The guiding cooperation of the four guide posts 54a and the linear bearing 53a meets the requirements of automatic lifting adjustment.

[0070] There are four guide posts 54a, which are evenly arranged longitudinally on the four corners between the upper fixing piece 51a and the lower fixing piece 52a. The upper end of each guide post 54a is connected to the upper fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com