Square-bar-shaped material edge defect sorting machine and controlling method

A sorting machine and electromechanical control technology, applied in sorting and other directions, can solve the problems of difficult manual judgment and easy misjudgment, achieve high practical value, low labor intensity, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

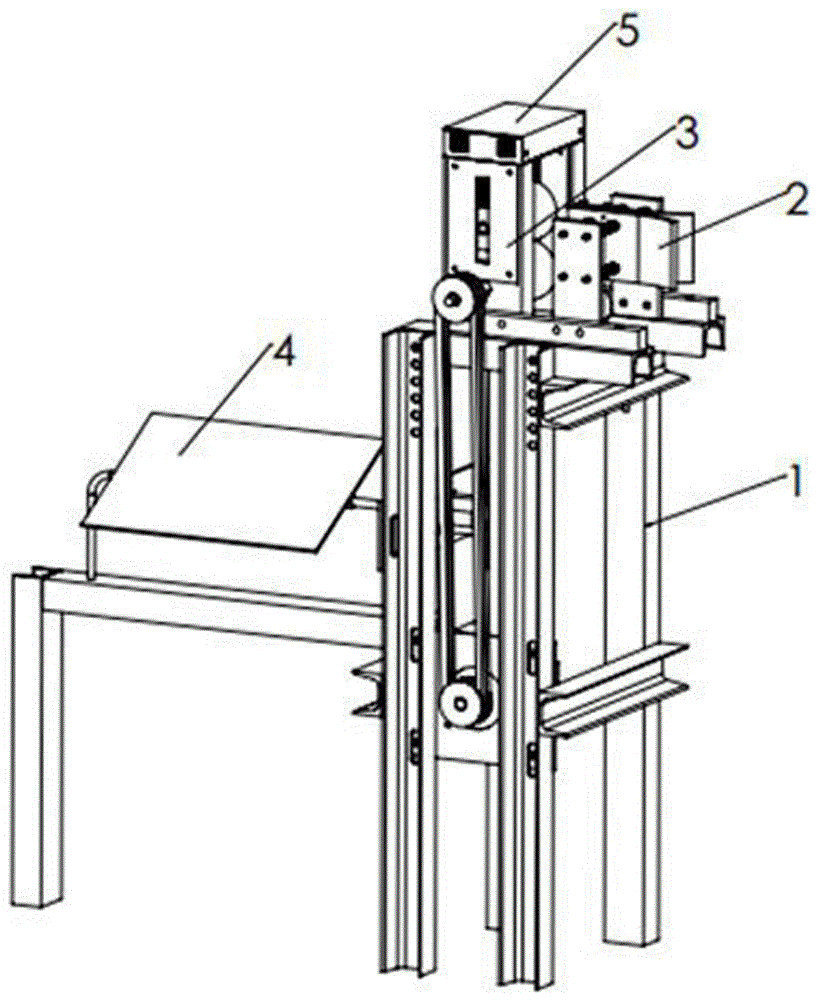

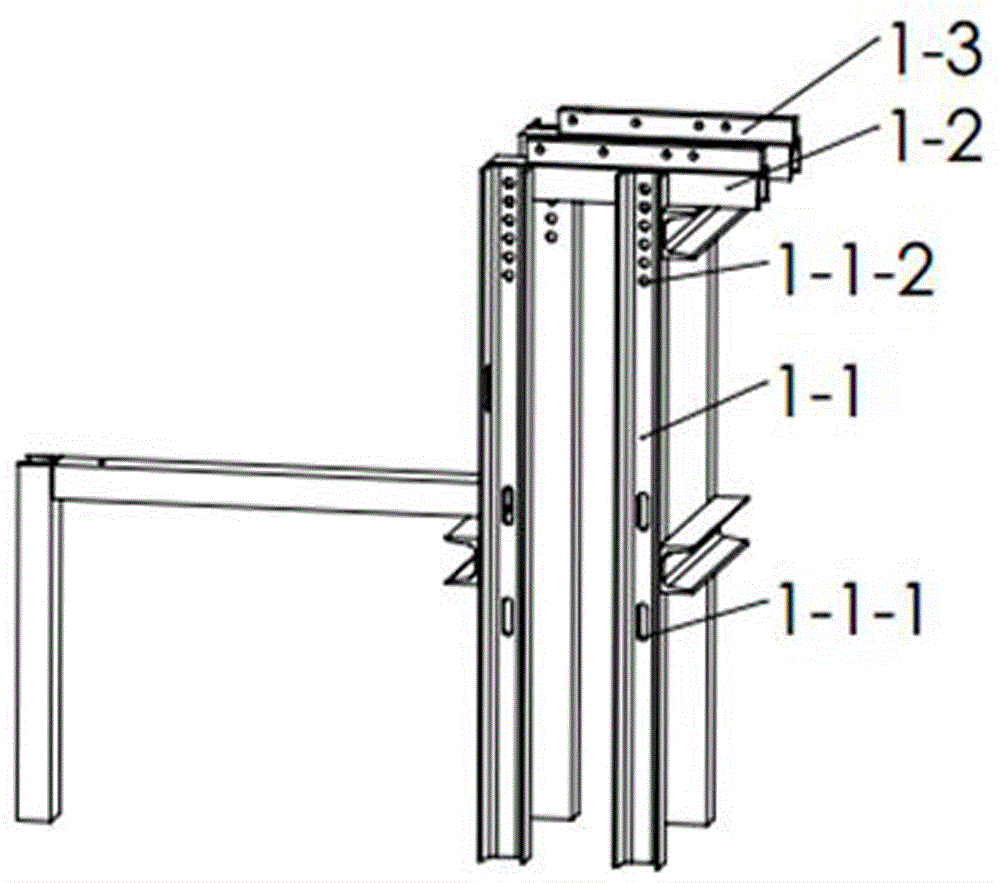

[0031] Such as figure 1 As shown, a sorting machine with edge defects of square strip materials includes a frame 1, a missing edge detection device 2, a conveying device 3, a sorting device 4 and an electromechanical control module 5; the missing edge detection device 2 communicates with the The frame 1 is connected, and the material inlet of the feeding and clamping mechanism in the missing edge detection device 2 is docked with the outlet of the square strip material production machine; the conveying device 3 is located at the material outlet of the feeding and clamping mechanism in the missing edge detecting device 2 and fixed on the frame through the motor plate 3-1; the sorting device 4 is installed on the frame 1 through the motor plate 3-1, and is located at the exit of the conveying device 3; the electromechanical control module 5 and the missing edge detection device 2 1. The sorting device 4 is connected to control the sorting and testing process of the whole sorting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com