Liquid forging forming method for welding-neck flange, forming die and forming device

A high-neck flange and forming die technology, which is applied in the field of liquid forging forming of high-neck flanges, forming die and forming device, can solve the problems of uneven flange performance, reduced precision of parts, affecting the quality of parts, etc. To achieve the effect of improving the pressure effect and improving the quality of the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

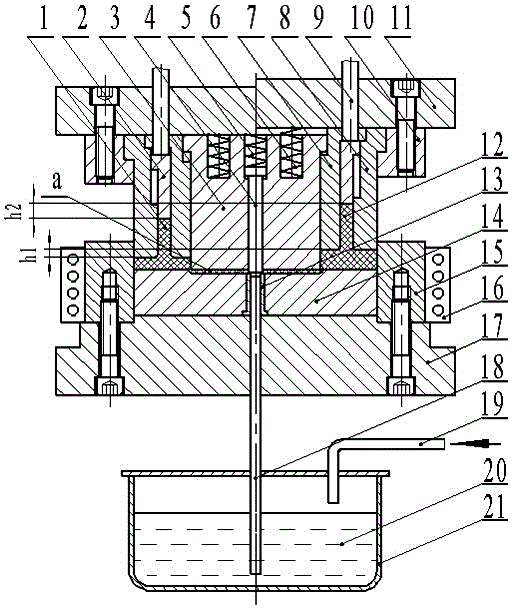

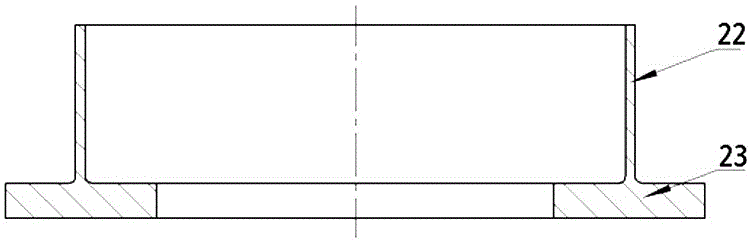

[0026] The embodiment of the forming device in the present invention: as figure 1 As shown, the forming device is a forming device for aluminum alloy high-neck flange parts with inner flanges, which is mainly composed of a forming die and a low-pressure pouring system. The structure of the liquid forging to be prepared is as follows figure 2 As shown, the liquid forging is composed of an annular disk portion 23 and a cylindrical neck portion 22 coaxially disposed at the upper end thereof.

[0027] The forming die is mainly composed of an upper die and a lower die set up and down opposite to each other. The upper die is used to connect to the movable beam of the hydraulic press, the lower die is used to connect to the working table of the hydraulic press, and the extrusion ring 2 is connected to the hydraulic mechanism through the pressure rod. The connection, hydraulic mechanism and movable beam are relatively independent. Through the reciprocating opening and closing of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com