Processing method and device for waterproof paper face plasterboard

A paper-faced gypsum board and processing method technology, applied in the direction of surface layering devices, manufacturing tools, ceramic molding machines, etc., can solve the problems of the decline in the qualified rate of finished boards, foaming of the boards, and large space for breathing and ventilation, so as to improve the qualified rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

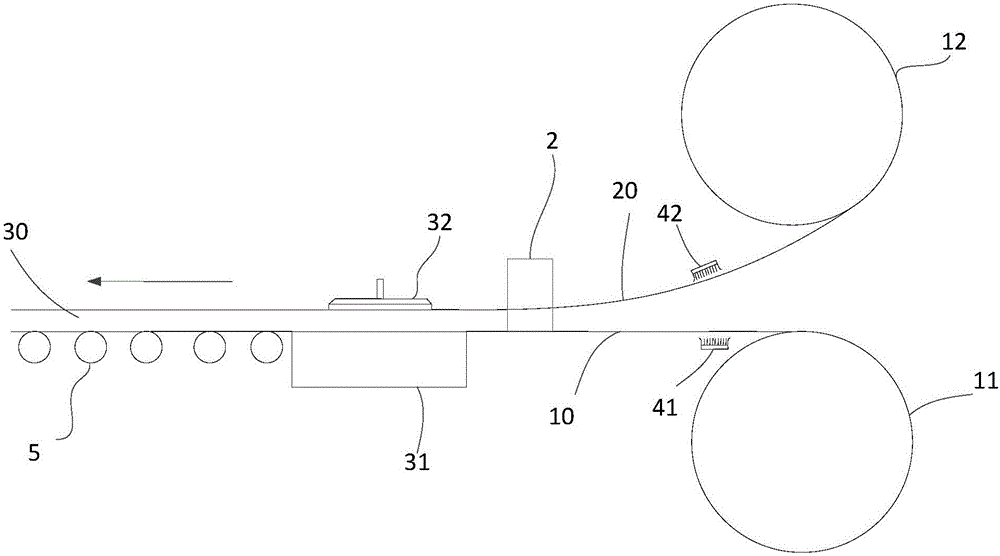

[0019] see figure 1 , the present invention provides a waterproof paper-faced gypsum board processing method and processing device, and the processing flow will be described in detail in conjunction with the device below:

[0020] First, roll out the protective paper wound on the roll of the upper paper machine, and use the protective paper on the lower roller 11 below as the lower paper surface 10, and spread it flat on the forming table 31 of the platen machine, and the upper upper roller 11 above it The protective paper on the roller 12 is located above the lower paper surface 10 as the upper paper surface 20, and passes under the extrusion plate 32 of the plate press machine;

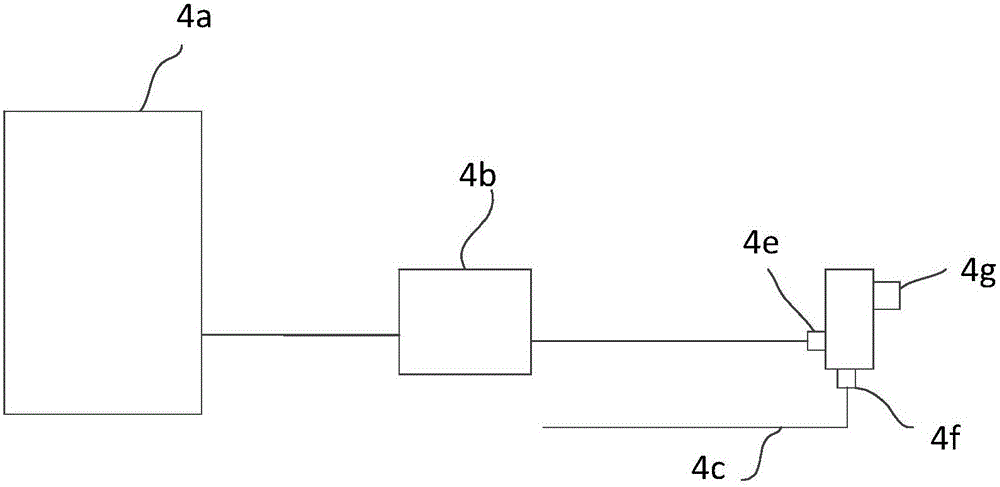

[0021] Before the protective paper enters the platen press, fill the gypsum board wet material on the paper surface 10 through the outlet of the mixer 2. There is no need to add gypsum waterproofing agent to the wet material of the gypsum board, but before the protective paper passes through the mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com