Molten channel type core induction boiler for aluminum plating production line

A technology of production line and melting channel, which is applied in hot-dip plating process, metal material coating process, coating, etc., can solve the problem of reducing the service life of induction heaters, blocking the melting channel of induction heaters, reducing the corrosion resistance of refractory materials, etc. problem, to achieve the effect of improving corrosion resistance, shortening service life and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to better understand the technical solution of the present invention, the following will be described in detail through specific embodiments in conjunction with the accompanying drawings:

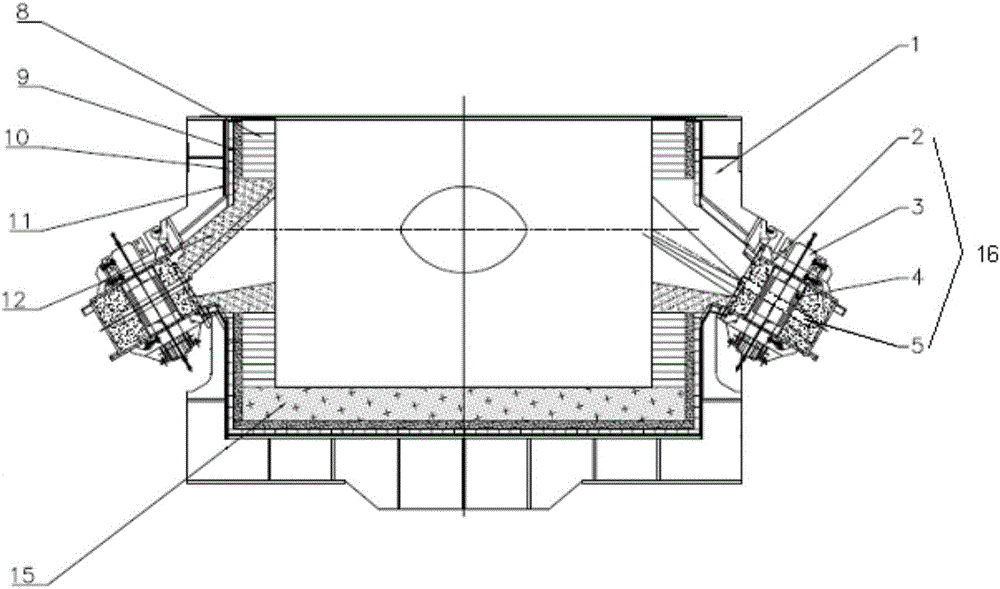

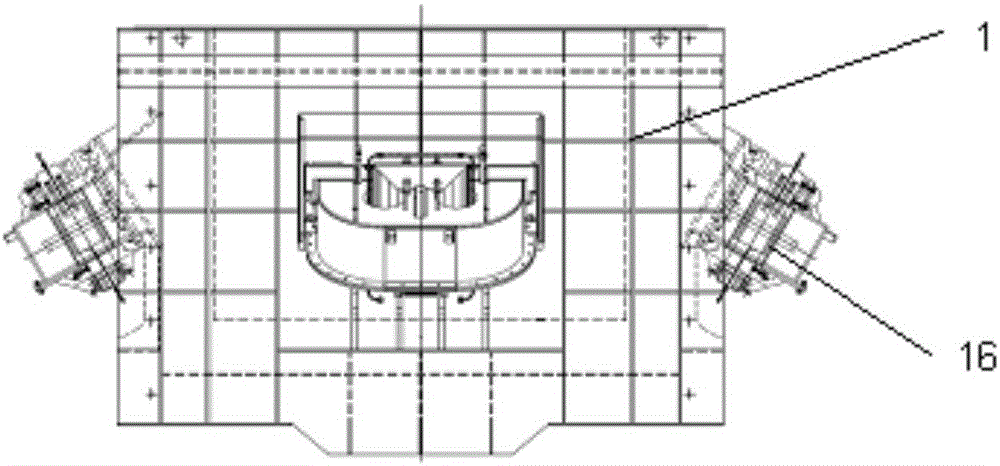

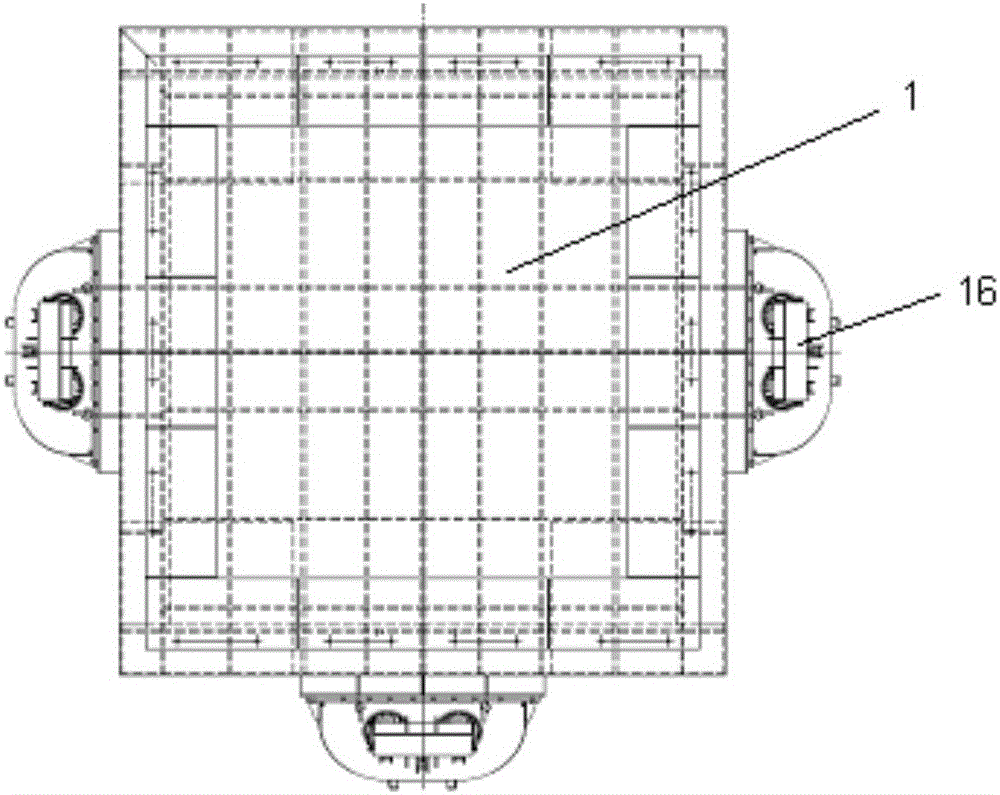

[0016] see figure 1 and figure 2 , a melting channel type cored induction pot used on an aluminum plating production line of the present invention includes a pot body and an induction heater 16 .

[0017] The pot body includes a pot shell 1, an insulation board 11, an insulation brick 10, a conventional castable 9, a high alumina brick 8 and a high alumina castable 15. The pot shell 1 is a cuboid, the top of the pot shell 1 is open, and the outer surface of the surrounding wall and the bottom surface of the pot shell 1 is welded with reinforcing ribs, and the steel shell adopting the reinforcing ribs can prevent the pot shell 1 from deforming. Insulation board 11 is arranged on the inner surface of the surrounding wall and bottom of pot body 1; Insulation brick 10 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com