Diversion tunnel plugging structure for initial water storage and rapid plugging method of diversion tunnel

A diversion tunnel, fast technology, applied in the diversion tunnel plugging structure, water conservancy and hydropower construction, the field of diversion tunnel rapid plugging, can solve the problem of weakening the combined bearing effect of temporary plugs and permanent plugs, permanent plug design Long and prolong the construction period, etc., to achieve excellent flow and water-stop performance, reduce construction difficulty, and improve the effect of anti-seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] The above structure can refer to the following design methods:

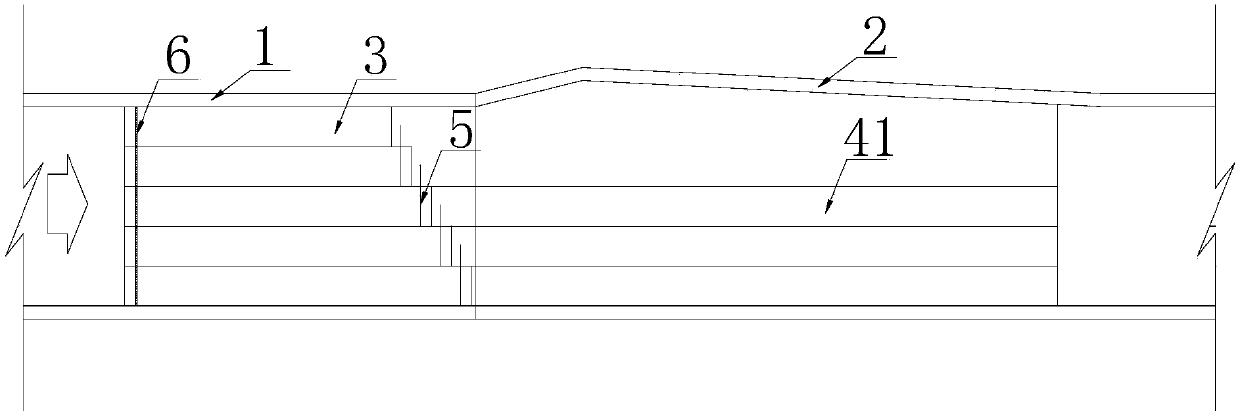

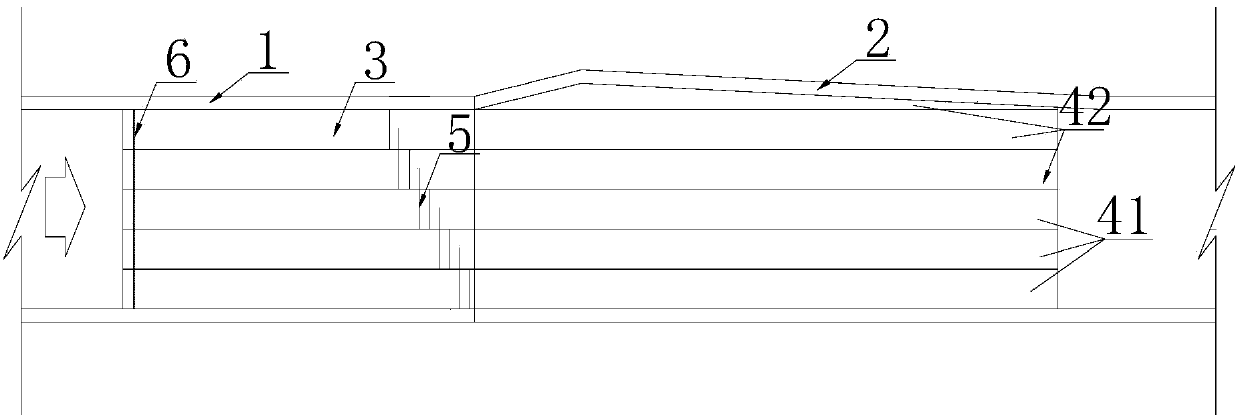

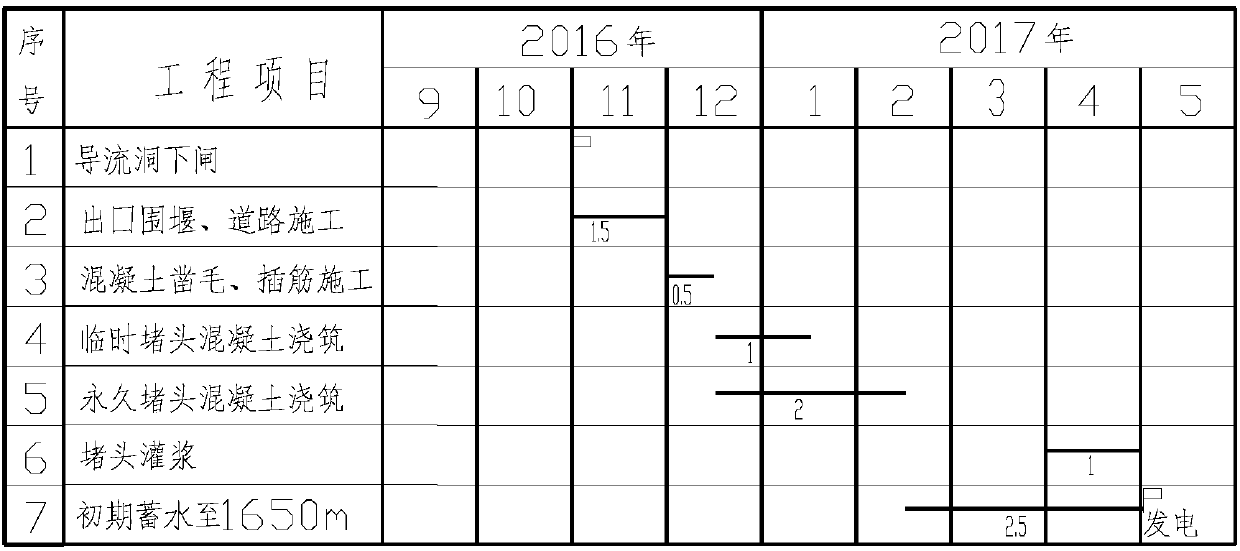

[0037]The facing surface of the permanent plug is in the shape of an inverted ladder, and is closely combined with the temporary plug 3 . When starting to store water to the dead water level of power generation at the initial stage, the initial water storage plug 41 meets the thickness of each layer of concrete pouring and is the same as the temporary plug, which is 3m / layer. Among them, the pouring length and rising height of the initial water storage plug 41 must meet the requirements of the anti-sliding stability calculation. In the calculation, only the resistance effect of the bottom plate is considered, and the gravity only considers the weight of the poured part. For specific calculation methods, refer to "Code for Design of Hydraulic Tunnels" 》DL / T5195-2004, after calculation, the length of the temporary plug 3 is taken as 20m, and the length of the initial water storage plug 41 and the normal wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com