Remote-monitoring and intelligent-temperature-control control system of ceramic kiln

A remote monitoring and intelligent temperature control technology, applied in gas fuel burners, combustion methods, combustion types, etc., can solve the problems of incomplete combustion of gas, increased heat loss, waste of gas energy, etc., to achieve accurate parameters, improve Accuracy and the effect of reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

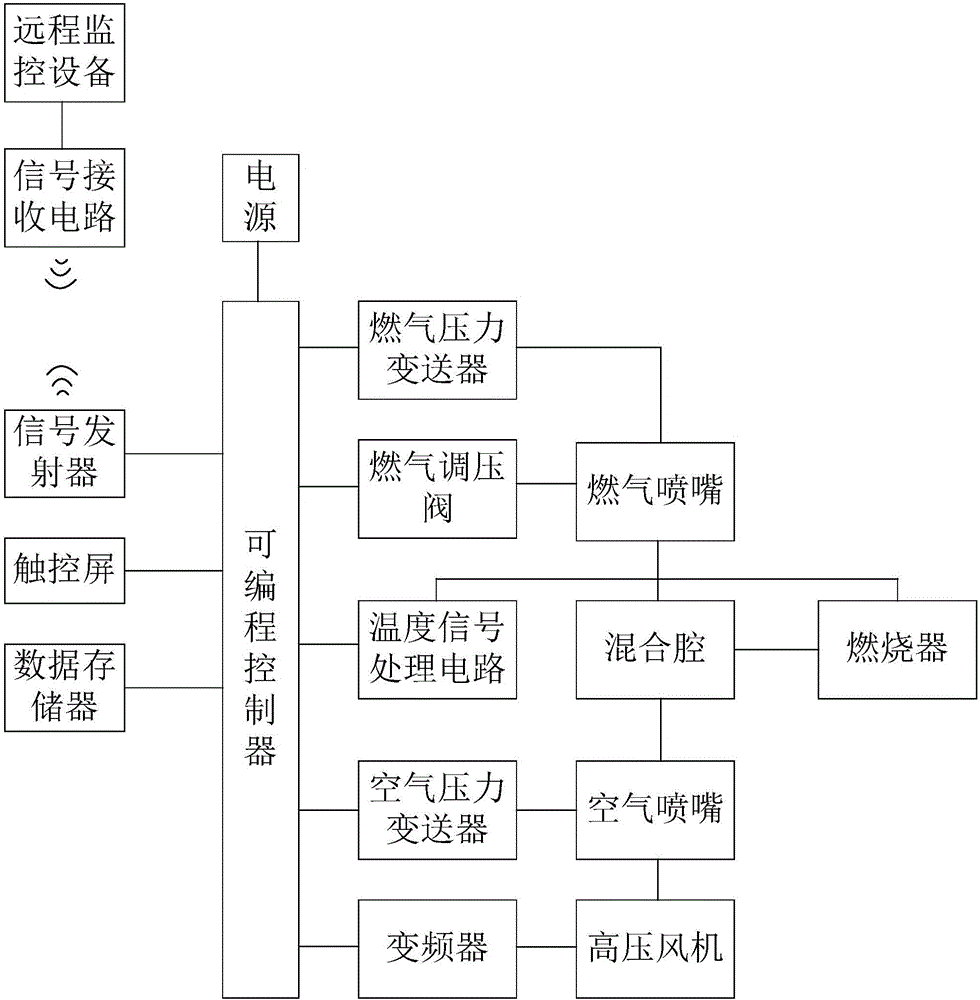

[0020] like figure 1 As shown, the ceramic kiln remote monitoring intelligent temperature control control system includes a programmable controller, a power supply connected to the programmable controller, a gas pressure regulating valve and a frequency converter respectively connected to the programmable controller, and a gas regulator. The gas nozzle connected with the pressure valve, the high-pressure blower connected with the frequency converter, the air nozzle connected with the high-pressure blower, the mixing chamber connected with the gas nozzle and the air nozzle at the same time, the burner connected with the mixing chamber, and respectively The remote monitoring equipment, touch screen and data memory connected with the programmable controller; the remote controller is wirelessly connected with the signal transmitter set on the programmable controller through the signal receiving circuit set on it; on the gas nozzle A gas pressure sensor is provided, and the gas pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com