Precise leveling detection method based on differential technology and telescopic indium steel bar code ruler

A technology of bar code ruler and indium steel, which is applied in the field of engineering survey and geodetic survey, and can solve the problems such as the influence of the accuracy of telescopic joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

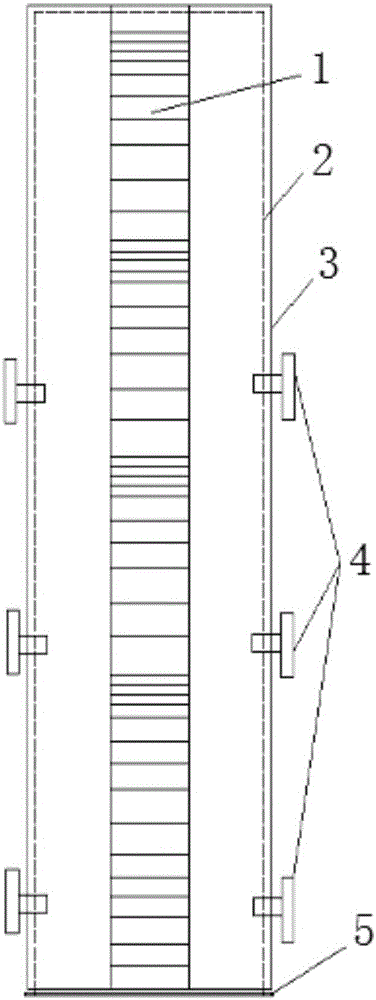

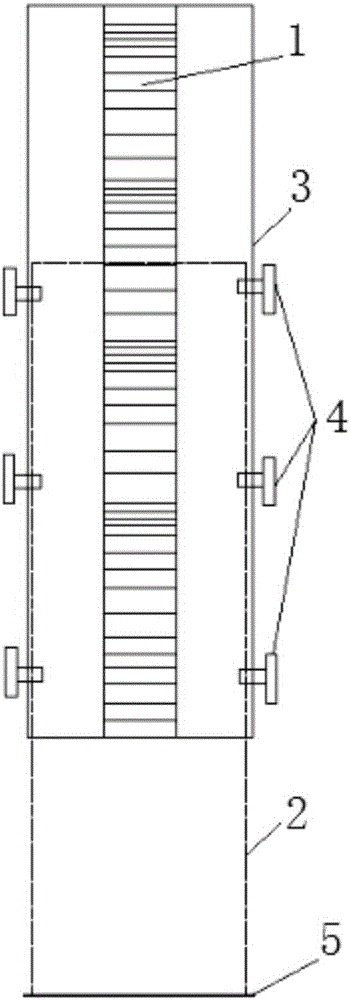

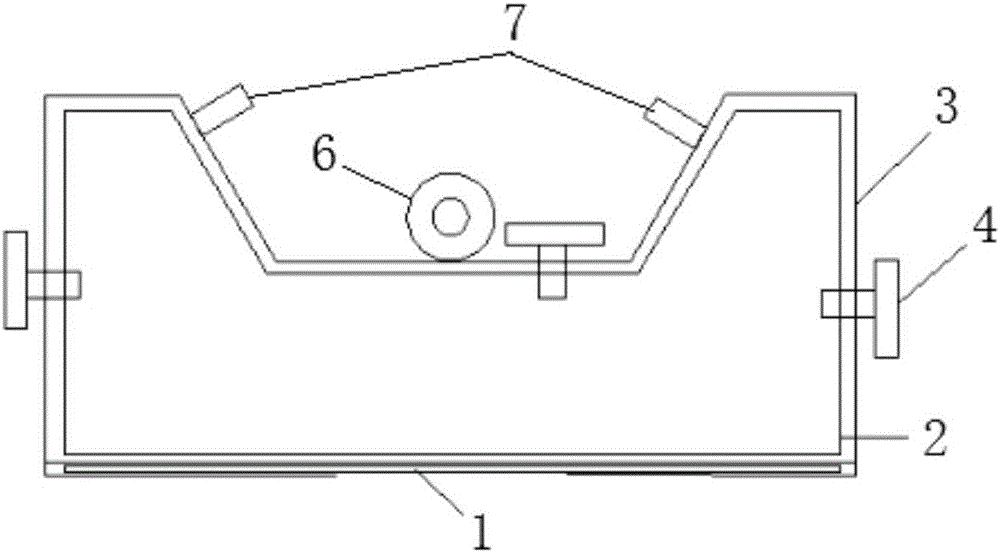

[0042] Such as Figure 1 to Figure 3 As shown, a scalable indium steel bar code ruler includes an inner rectangular steel pipe 2, an outer rectangular steel pipe 3 and a screw pin 4, the inner rectangular steel pipe 2 is sleeved in the outer rectangular steel pipe 3, and the outer rectangular steel pipe 3 is provided with the The screw pin bolt 4 is provided with an indium steel barcode tape 1 on the front side of the outer rectangular steel pipe 3, and a circular level is provided on the rear side, and the vertical position of the retractable indium steel barcode ruler is adjusted by the circular bubble 6 in the circular level. The retractable indium steel bar code ruler of the present invention utilizes the inner rectangular steel pipe and the outer rectangular steel pipe that are set together to realize the expansion and contraction of the length of the indium steel bar code ruler. Stability, effectively guarantee the accuracy in the measurement process.

[0043] In the em...

Embodiment 2

[0048] A stretchable indium steel bar code ruler, the structure is as described in Example 1, the difference is that the length of the outer rectangular steel pipe is 1500mm, and the length of the inner rectangular steel pipe is 1480mm. Five groups of said screw pins 4 are arranged on the outer rectangular steel pipe 3, and each group includes three screw pins 4. When the length of the inner rectangular steel pipe and the outer rectangular steel pipe is longer, a screw pin group can be added to increase the stability of the connection after elongation.

Embodiment 3

[0050] A kind of retractable indium steel bar code ruler, structure as described in embodiment 1, its difference is: be provided with a base 5 at the bottom of inner rectangular steel pipe 2, base 5 selects a thickness to be the steel plate of 8mm for use, base 5 The surface area is greater than the cross-sectional area of the outer rectangular steel pipe 3. A base 5 is provided at the bottom of the inner rectangular steel pipe 2, which is beneficial to the placement of the indium steel barcode ruler and increases the stability of the indium steel barcode ruler during measurement.

[0051] In addition, the rear sides of the inner rectangular steel pipe 2 and the outer rectangular steel pipe 3 are arranged in trapezoidal grooves, and handrails 7 are arranged on the two side walls of the trapezoidal grooves. The advantage of this design is that when carrying out leveling, the handrail 7 is convenient for the operator to grasp the indium steel bar code ruler.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com