Designing and prediction method for converting high-temperature stress relaxation data into creep data

A technology of stress relaxation and creep data, applied in the field of design prediction of high temperature creep

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

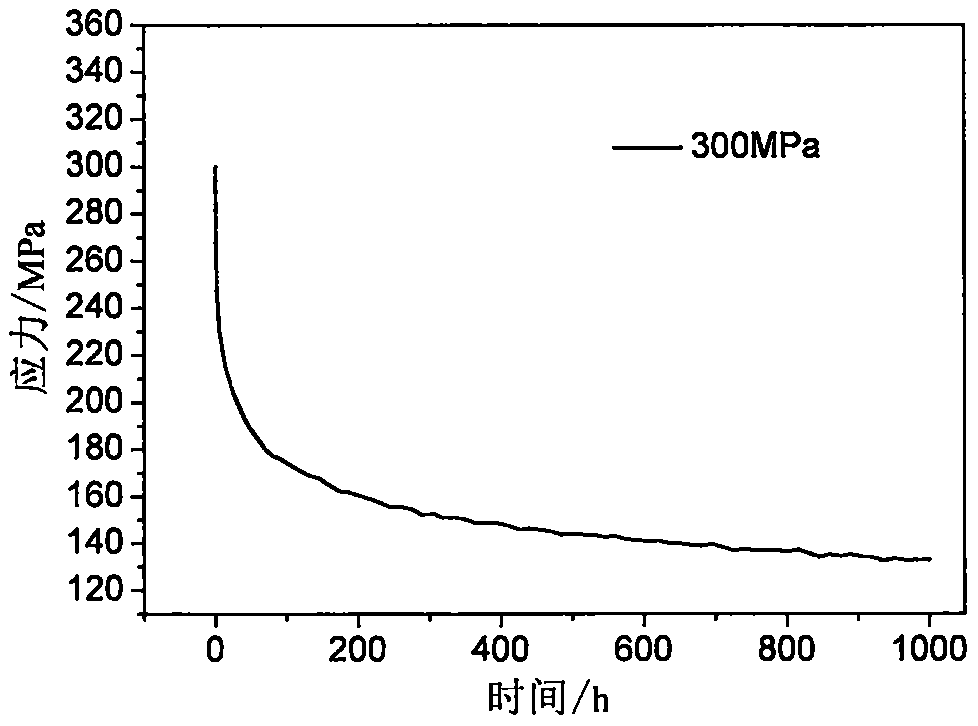

[0080] Domestic 1Cr10NiMoW2VNbN steel is used for steam turbine rotors, blades and bolts below 600 °C. This material is used as an example for further explanation. It should be understood that the following examples are for the purpose of illustration only, and are not intended to limit the scope of the present invention.

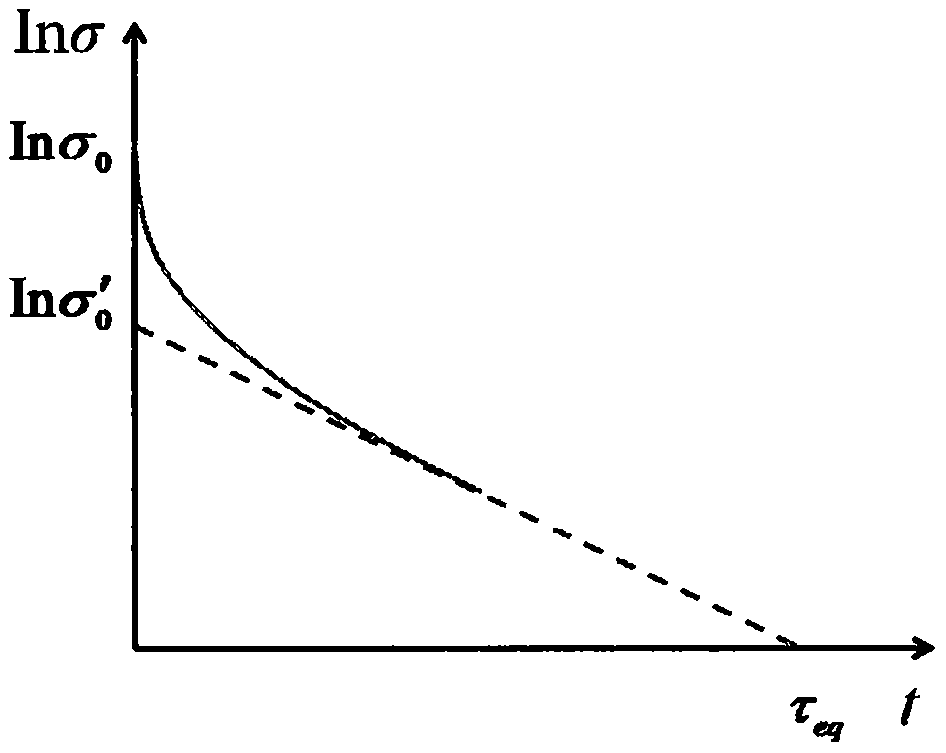

[0081] 1. Establish a two-stage stress relaxation equation

[0082] σ = σ 0 [ e - k t 1 + p t - e - k p ( 1 - e - t t ...

Embodiment 2

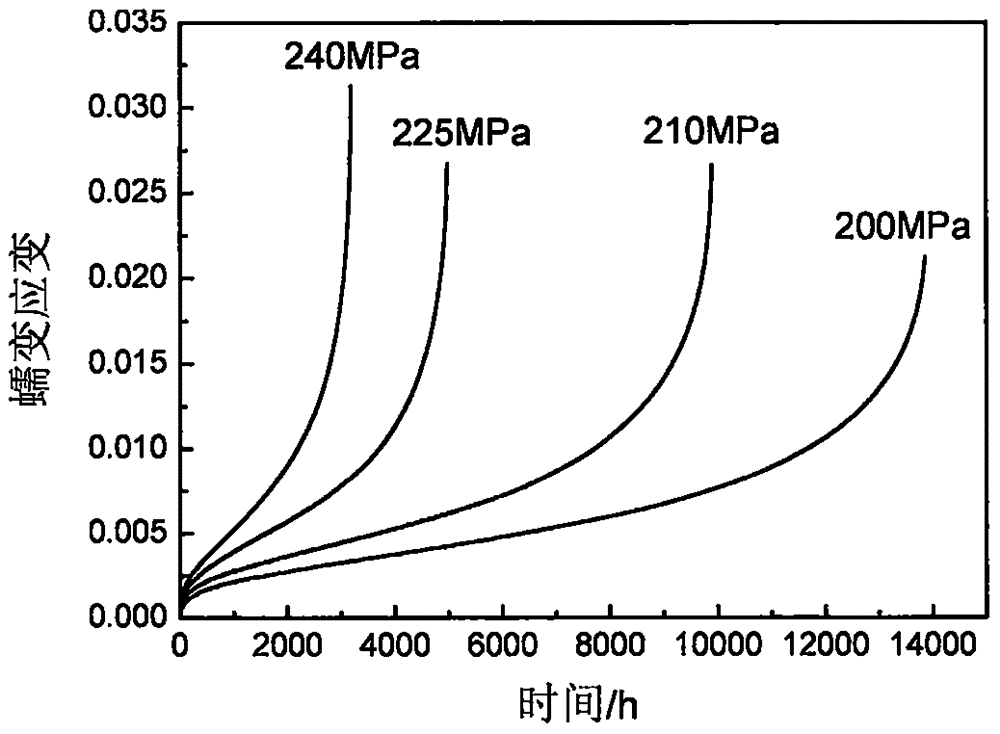

[0094] In order to verify the conversion results, creep tests at four stress levels of 200, 210, 225, and 240 MPa at 600 °C were carried out, such as image 3 Shown; The conversion result of the present invention and experimental result are drawn respectively in appendix Figure 4 , 5 The dotted line in the figure is the test result, and the solid line is the conversion result. From attached Figure 4 , 5 It can be seen that the conversion results are generally in good agreement with the actual creep data, which shows that the relaxation-creep conversion method is reliable. This also shows that coordinating the equivalent creep rate of the two stages of relaxation is more suitable for simulating the steady-state creep rate, and this conversion model and method can be used for high-temperature creep strength design and life prediction. At the same time, it also shows that using a single 1000-hour stress relaxation test, multiple creep data under any stress, or even tens of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com