Prediction method for residual stress and damage caused by stress relaxation of high-temperature material

A technique of stress relaxation and residual stress, used in analyzing materials, measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Domestic 1Crl0NiMoW2VNbN steel, used for 600. Below C, steam turbine rotors, blades and bolts, take this material as an example for further explanation. It should be understood that the following examples are only for illustrative purposes, and not for limiting the scope of the present invention.

[0055] 1. Get creep data

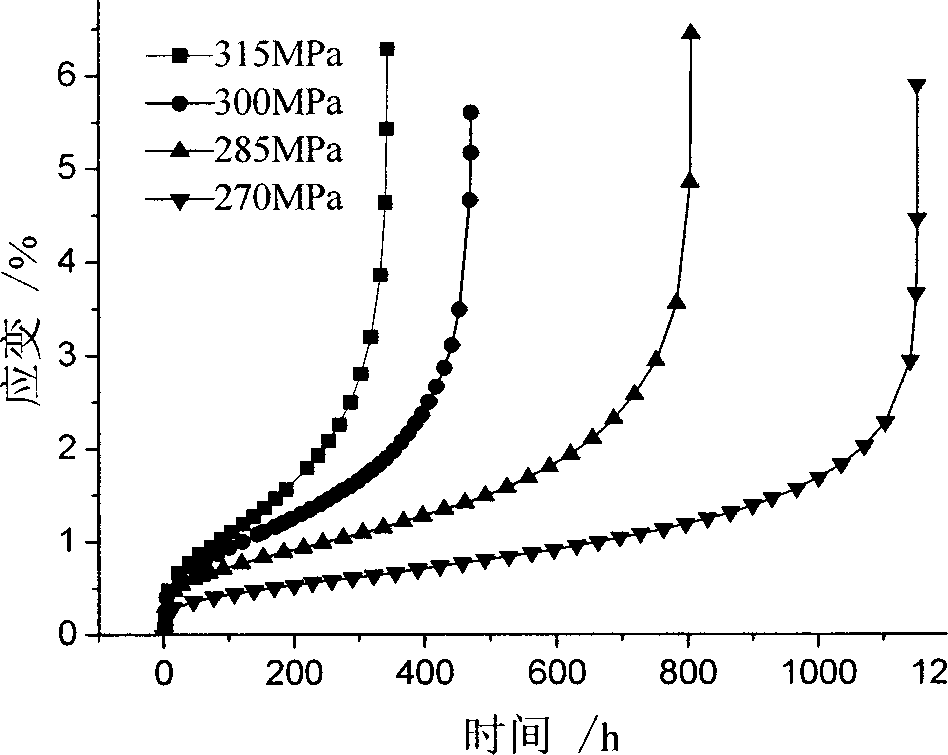

[0056] The creep test is a unidirectional creep tensile test at 600℃, the creep stress is 315, 300, 285, 270 MPa, the test data is as attached figure 1 Shown.

[0057] 2. Parameter fitting

[0058] The test data is combined with multi-level linear and nonlinear regression to obtain the material constants. 600. The material elastic modulus E under C is 1.68×10 5 MPa, J-H creep model material constants K, A, n, m, p, q are: 6.7×10 -33 , 1.28×10 -24 , 11.19, 11.12, 8.1l, 6.83, O-H creep model material constants G, B, d, β, δ, φ, In order: 3.6×10 -17 , 4.14×10 -11 , 5.157, 10.02, -0.60, 3.29, 4.75.

[0059] 3. Establish the concrete expression of the stress...

Embodiment 2

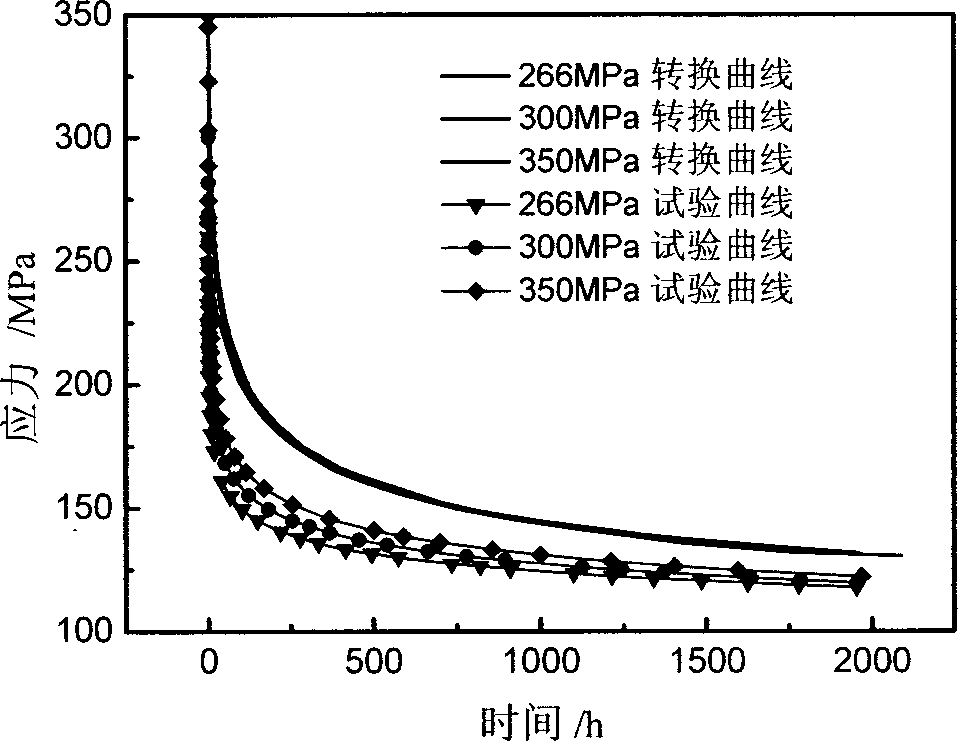

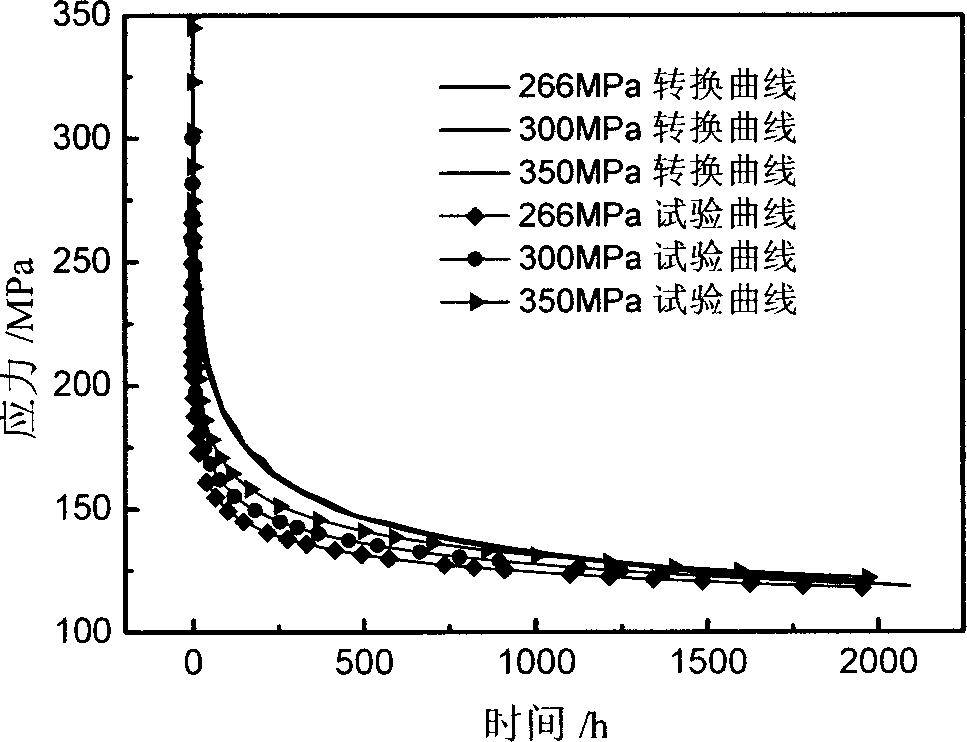

[0073] In order to verify the conversion results, stress relaxation tests with three initial stress levels of 350, 300, and 266 MPa at 600°C were carried out; the conversion results of the present invention and the experimental results are shown in the attached file. figure 2 , 3 To compare. Attached figure 2 , 3 It can be seen that the conversion result of the stress relaxation continuous damage model based on the JH creep damage model of the present invention is slightly higher than the experimental results, while the conversion result of the stress relaxation continuous damage model based on the OH creep model is in good agreement with the experimental results. This may be related to the latter (the former does not) characterize the first stage of creep corresponding to stress relaxation, so the latter is recommended. In addition, the long-term conversion results of the three initial stress levels of the two relaxation damage models are basically gathered into a curve, whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com