High-efficient spool take-up machine

A technology of I-shaped wheel and wire take-up machine, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of troublesome installation and disassembly of the I-shaped wheel, high labor intensity, etc., and achieves convenient installation and Effort-saving, easy disassembly and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

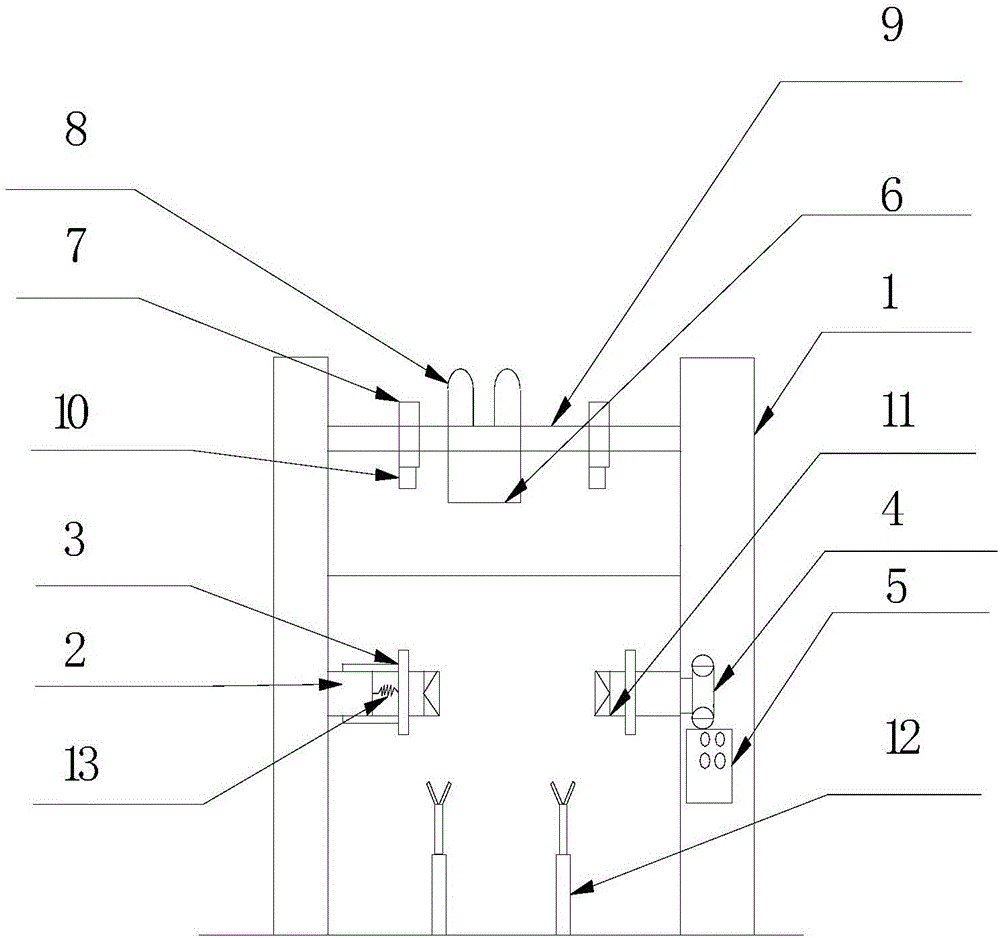

[0014] refer to figure 1 , a high-efficiency I-shaped wheel take-up machine of the present invention, comprising a body support frame 1, a telescopic shaft base 2, a telescopic shaft 3, a shaft rotation motor 4, an electric control device 5, a wire wheel movement motor 6, a row Wire wheel limiter 7, line wheel 8, line wheel movement track 9, sensor 10, fixed support shaft 11, telescopic hydraulic support frame 12 and spring 13, said fixed support shaft 11 and shaft rotating motor 4 phase connected, the electric control device 5 is respectively connected to the inductor 10, the wire-discharging wheel motor 6 and the shaft rotating motor 4 through wires, and the wire-discharging wheel motor 6 is directly connected to the wire-discharging wheel 8, and the wire-discharging wheel The wheel 8 is directly installed on the moving track 9 of the wiring wheel, the telescopic shaft base 2, the moving track 9 of the wiring wheel and the fixed support shaft 11 are directly installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com