A kind of sealing glass powder for electric connector and its preparation method and sealing process

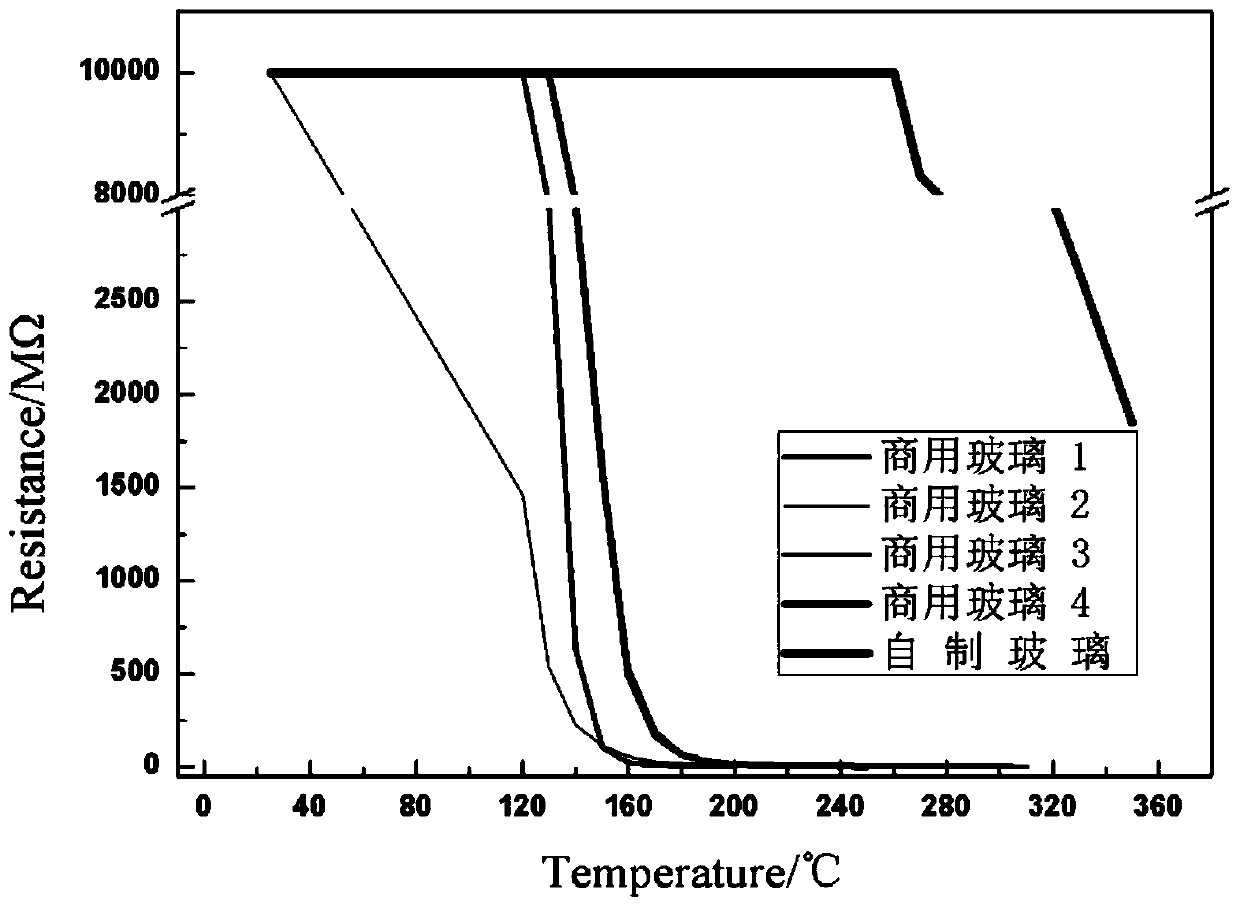

A technology for sealing glass and electrical connectors, which is applied in connection, line/collector components, circuits, etc., can solve problems such as failure to meet performance requirements, decrease in product resistance, and poor product stability, so as to improve chemical stability and Effects of electrical insulation, lower melting temperature, and improved chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] A preparation method of sealing glass powder for electrical connectors, specifically comprising the following steps:

[0071] 1), select raw material by following weight percentage:

[0072] K 2 O: 3%-7%

[0073] MgO: 1%-5%

[0074] CaO: 3%-7%

[0075] SrO: 0.5%-2%

[0076] BaO: 20%-30%

[0077] ZnO: 0.05%-1%

[0078] Fe 2 o 3 : 0.05%-1%

[0079] al 2 o 3 : 5%-15%

[0080] SiO 2 : 40%-60%

[0081] ZrO 2 : 0.5%-1.5%

[0082] TiO 2 : 0.05%-1%

[0083] V 2 o 5 : 1%-7%

[0084] Na 3 AlF 6 : 1%-3%;

[0085] 2), put the above ingredients in a ball mill for ball milling, so that the ingredients are mixed evenly, the grinding speed is 300r / min, and the time is 20-40min;

[0086] 3), then put the ball-milled and mixed materials in a corundum crucible or a platinum crucible, place the crucible in a silicon-molybdenum furnace, and raise the temperature from room temperature to 700-900°C at a rate of 10°C / min under air. After heat preservation at 700-900°C ...

Embodiment 1

[0100] A sealing glass powder for electrical connectors, prepared from the following raw materials in percent by weight: K 2 O is 3%, MgO is 2%, CaO is 4%, SrO is 0.5%, BaO is 26%, ZnO is 0.9%, Fe 2 o 3 0.05%, Al 2 o 3 15%, SiO 2 45%, ZrO 2 0.5%, TiO 2 0.05%, V 2 o 5 2%, Na 3 AlF 6 1%.

[0101] A preparation method of sealing glass powder for electrical connectors, specifically comprising the following steps:

[0102] 1), select raw material by following weight percentage:

[0103] K 2 O is 3%, MgO is 2%, CaO is 4%, SrO is 0.5%, BaO is 26%, ZnO is 0.9%, Fe 2 o 3 0.05%, Al 2 o 3 15%, SiO 2 45%, ZrO 2 0.5%, TiO 2 0.05%, V 2 o 5 2%, Na 3 AlF 6 1%.

[0104] 2) Put the raw materials of the above-mentioned components in a ball mill for ball milling, so that the ingredients are mixed evenly, the grinding speed is 300r / min, and the time is 20min;

[0105] 3) Put the ball-milled and mixed materials in step (2) in a corundum crucible or a platinum crucible, plac...

Embodiment 2

[0124] A sealing glass powder for electrical connectors, prepared from the following raw materials in percent by weight: K 2 O is 4.5%, MgO is 3.5%, CaO is 5.5%, SrO is 0.75%, BaO is 21.5%, ZnO is 0.75%, Fe 2 o 3 0.5%, Al 2 o 3 10%, SiO 2 44.5%, ZrO 2 1%, TiO 2 0.5%, V 2 o 5 4%, Na 3 AlF 6 3%.

[0125] A method for preparing a sealing glass for an electrical connector, specifically comprising the following steps:

[0126] 1), select raw material by following weight percentage: K 2 O is 4.5%, MgO is 3.5%, CaO is 5.5%, SrO is 0.75%, BaO is 21.5%, ZnO is 0.75%, Fe 2 o 3 0.5%, Al 2 o 3 10%, SiO 2 44.5%, ZrO 2 1%, TiO 2 0.5%, V 2 o 5 4%, Na 3 AlF 6 3%,

[0127] 2) Put the raw materials of the above-mentioned components in a ball mill for ball milling, so that the ingredients are mixed evenly, the grinding speed is 300r / min, and the time is 15min;

[0128] 3) Put the ball-milled and mixed materials in step (2) into a corundum crucible or a platinum crucible, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com