Method for manufacturing fluorescent fabric for children's bags

A manufacturing method and school bag technology, which is applied in textiles, papermaking, and fiber treatment, can solve the problems of bad smell of fabrics and unsustainable fluorescent effect, and achieve the effect of maintaining fluorescent characteristics for a long time and improving long-lasting luminosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A method for manufacturing fluorescent fabrics for children's schoolbags, the steps are as follows:

[0018] 1) Soak the blended fiber in the fluorescent agent, the soaking temperature is 60°C, the soaking time is 4h, and then dried after soaking.

[0019] Fluorescent agent consists of 5 parts of dibutyl phthalate, 10 parts of petroleum ether, 1 part of film-forming aid, 3 parts of Al 2 o 3 , 1 part of organophosphine silane coupling agent and 70 parts of photo-induced energy storage luminous powder are mixed.

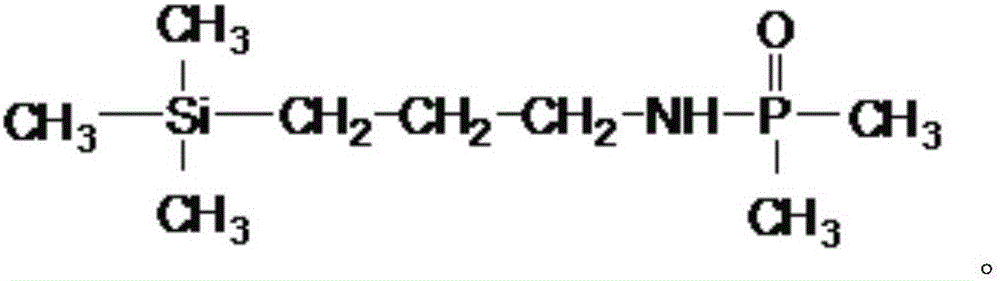

[0020] The structural formula of organophosphine silane coupling agent is:

[0021]

[0022] 2), blended fiber is processed into blended fabric (conventional method).

[0023] 3) Apply a layer of waterproof glue on the blended fabric (conventional method).

[0024] 4) Perform plasticizing treatment on the blended fabric, the plasticizing time is 5 hours, and the plasticizing temperature is 200°C.

Embodiment 2

[0026] A method for manufacturing fluorescent fabrics for children's schoolbags, the steps are as follows:

[0027] 1) Soak the blended fiber in the fluorescent agent, the soaking temperature is 70°C, the soaking time is 5h, and then dried after soaking.

[0028] The fluorescent agent consists of 16 parts of dibutyl phthalate, 5 parts of petroleum ether, 3 parts of film-forming aids, and 1 part of Al 2 o 3 , 3 parts of organophosphine silane coupling agent and 40 parts of photo-induced energy storage luminous powder are mixed.

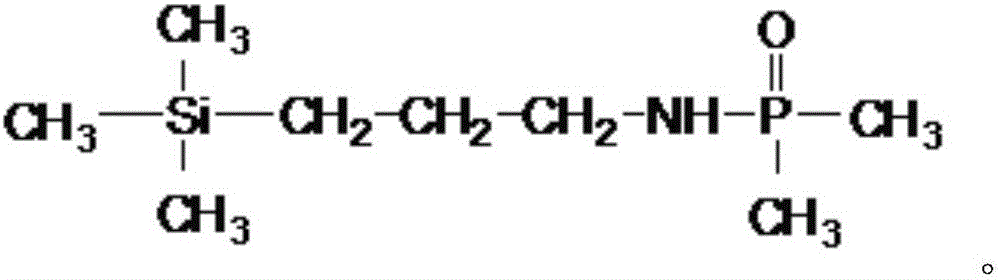

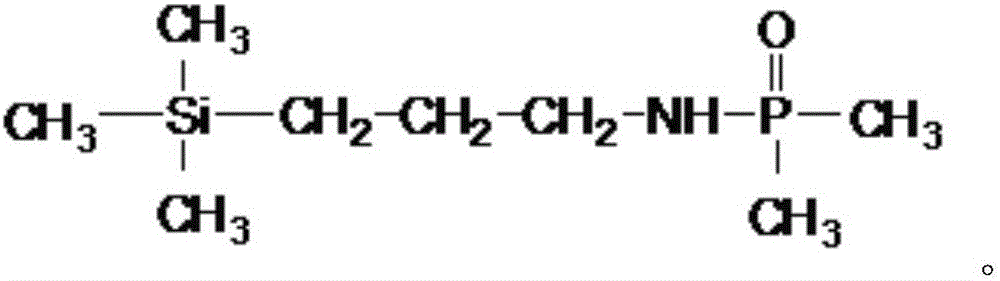

[0029] The structural formula of organophosphine silane coupling agent is:

[0030]

[0031] 2), blended fiber is processed into blended fabric (conventional method).

[0032] 3) Apply a layer of waterproof glue on the blended fabric (conventional method).

[0033] 4) Perform plasticizing treatment on the blended fabric, the plasticizing time is 10 hours, and the plasticizing temperature is 150°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com