Grab bucket of continuous wall

A wall grab and grab technology, which is applied in the field of underground construction machinery, can solve the problems of unreachable, residual, low efficiency, etc., and achieve the effect of being easy to fall off and improving the grabbing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

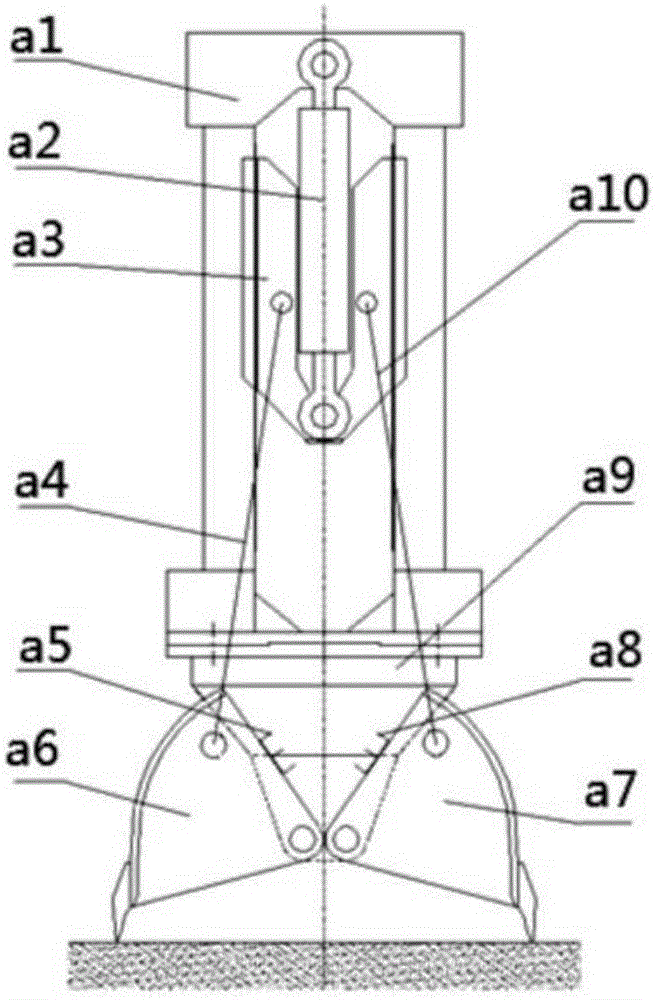

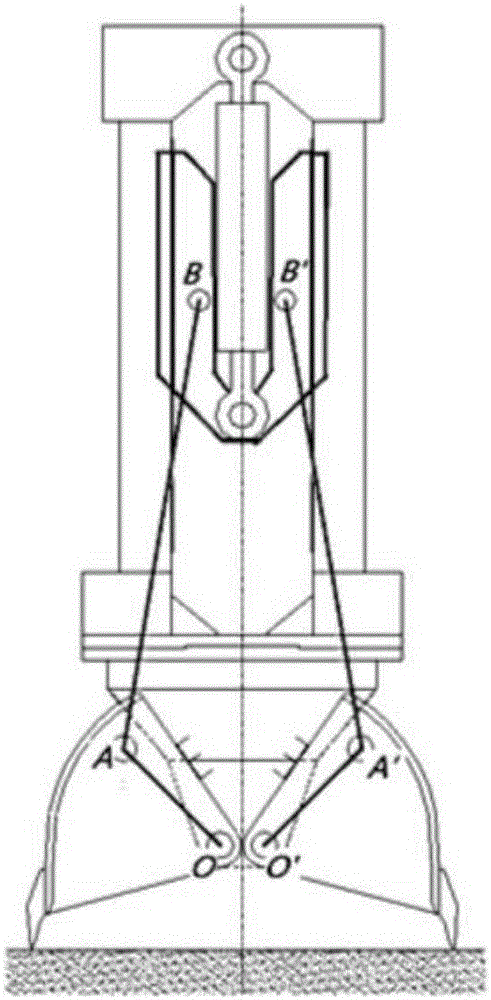

[0031] In order to facilitate the description of the solution to the existing problems of the existing diaphragm wall hydraulic grab, the structure of the existing diaphragm wall hydraulic grab is analyzed first. Such as figure 1 Shown is the structural schematic diagram of the existing diaphragm wall hydraulic grab. It can be seen from the figure that the slider a3 driven by the hydraulic cylinder a2 moves in the vertical direction, and the grab body a6, a7 is driven to rotate relative to the support a9 through the connecting rod a4, a10. The slider a3, the connecting rod a4, a10 and the grab body a6, 7 together form an equivalent slider crank mechanism, such as figure 2 shown. The vertical movement of B and B' makes A and A' rotate around 0 and 0' respectively to realize the opening and closing of the grab body. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com