A rapid air intake system for the lifting cylinder of the impact test bench

An air intake system, lift cylinder technology, applied in mechanical equipment, fluid pressure actuation devices, etc., can solve problems such as unreliable locking and unreliable locking of piston rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

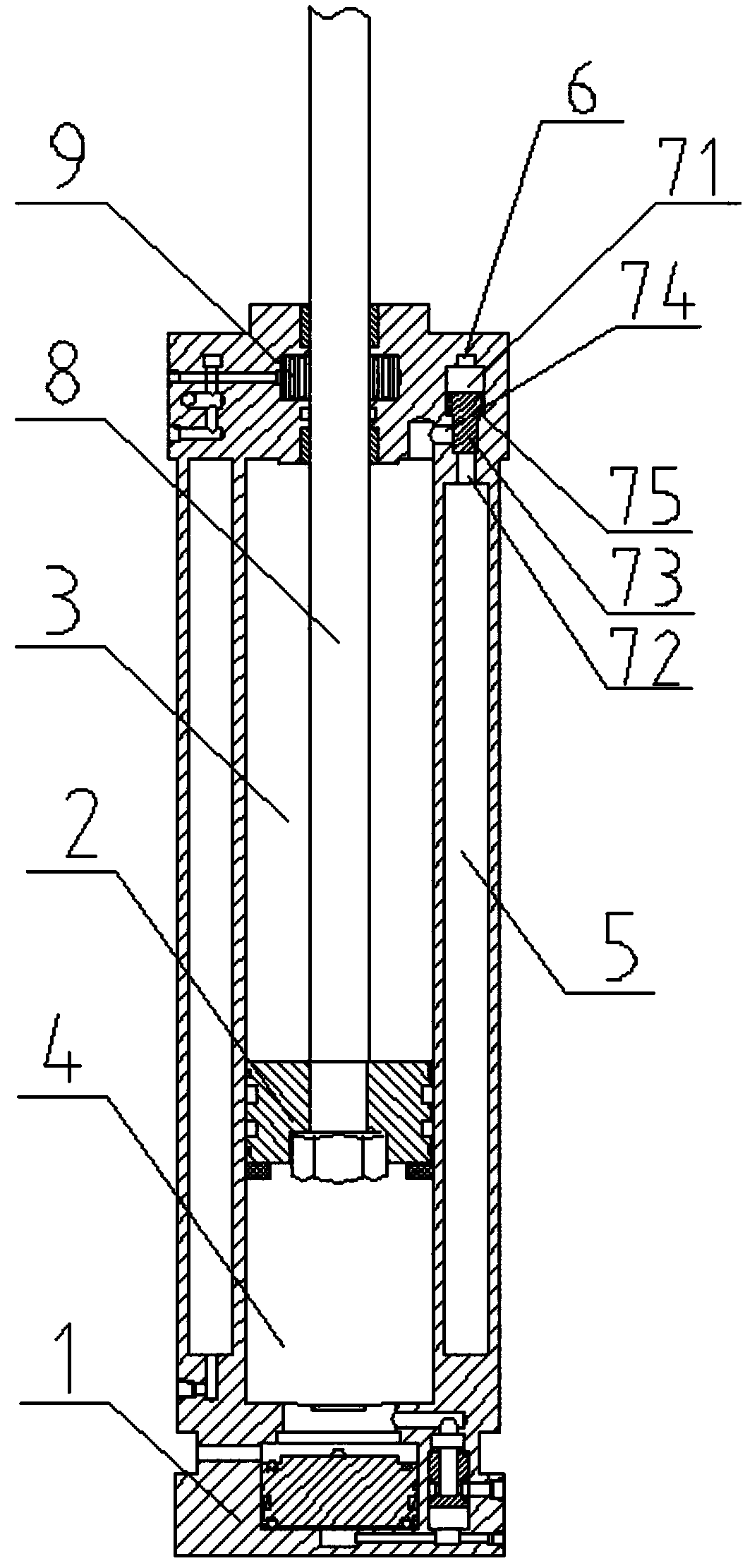

[0018] see figure 1 , as shown in the legend, a rapid air intake system for the lifting cylinder of an impact test bench. The lifting cylinder includes a cylinder body 1 and a piston 2. The cylinder body 1 is provided with a working chamber, and the piston 2 is dynamically sealed and slides up and down to connect the above working The side wall of the chamber divides the above-mentioned working chamber into a positive working chamber 3 located above and a reverse working chamber 4 located below. The above-mentioned rapid air intake system includes an annular air storage chamber 5 arranged outside the above-mentioned working chamber, The annular air distribution channel 6 arranged on the upper side of the above-mentioned working chamber and 7 air intake assemblies uniformly distributed along the horizontal ring direction, each air intake assembly includes a ventilation control chamber, a dynamic sealing sliding connection with the side wall of the ventilation control chamber An...

Embodiment 2

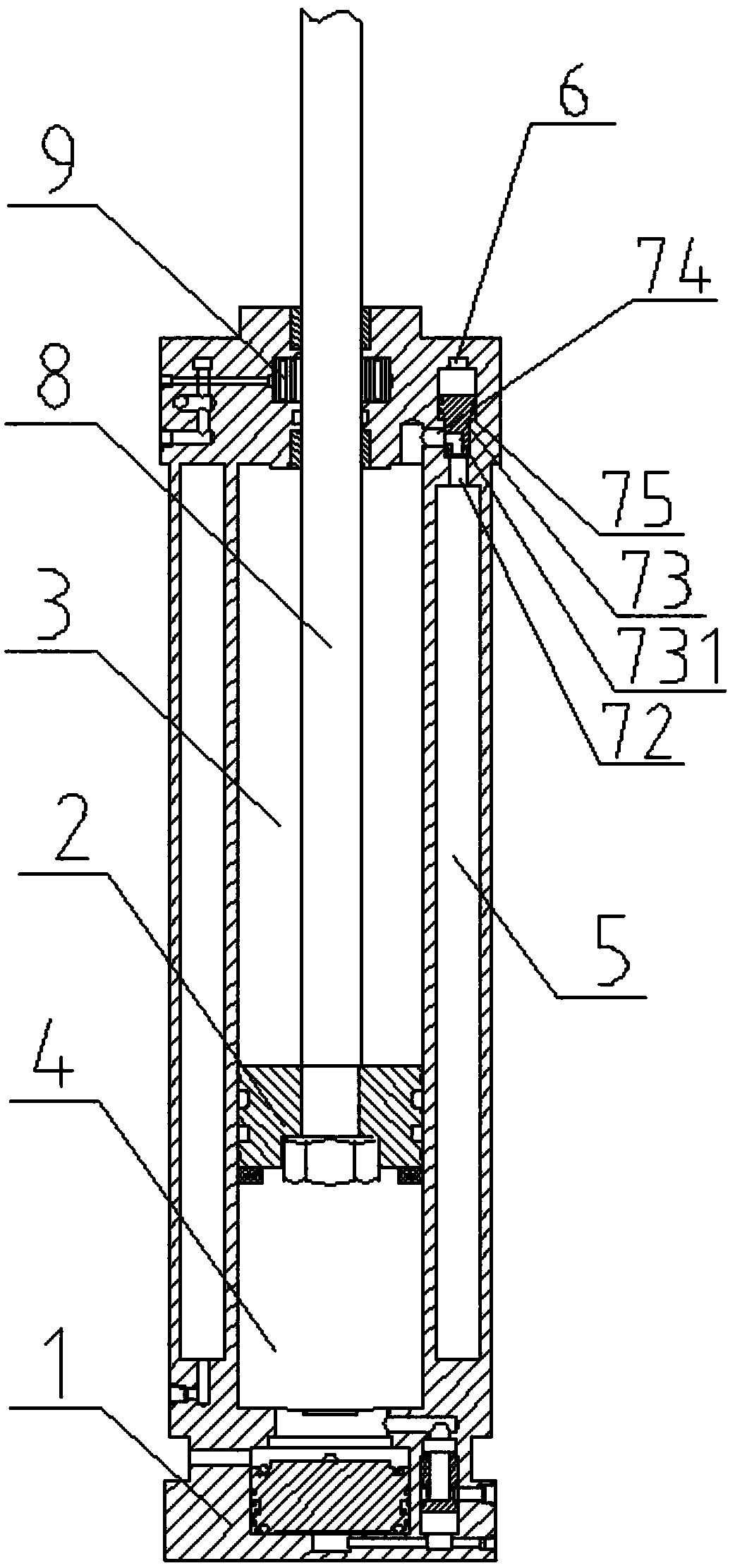

[0033] see figure 2 , as shown in the legend, the rest are the same as the first embodiment, the difference is that the sealing plug 73 is also provided with a vent channel 731, and the vent channel 731 communicates with the side wall of the vent chamber 72 and the sealing plug 73, and the vent port 74 is connected to the vent port 73. The channel 731 communicates or is blocked by the solid part of the sealing plug 73 .

[0034] When the positive working chamber 3 is not ventilated, the air in the control chamber 71 is discharged, and when the air pressure in the ventilation chamber 72 is less than the air pressure in the control chamber 71 to the set value, the sealing plug 73 moves to block the solid part of the sealing plug 73 Live the position of the ventilation port 74;

[0035] When ventilating to the working chamber 3, the air distribution channel 6 feeds the control air source into the control chamber 71, and when the air pressure in the control chamber 71 is greater...

Embodiment 3

[0037] The rest is the same as the first embodiment, except that the above-mentioned forward working chamber is a rodless chamber, and the above-mentioned reverse working chamber is a rod-bearing chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com