Novel flange seal washer

A flange sealing and gasket technology, which is applied in engine sealing, flange connection, pipes/pipe joints/fittings, etc., can solve the problems of poor sealing safety, gasket internal pressure breakthrough, low pressure, etc., and achieve improved sealing performance , Accurate installation and positioning, accurate positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

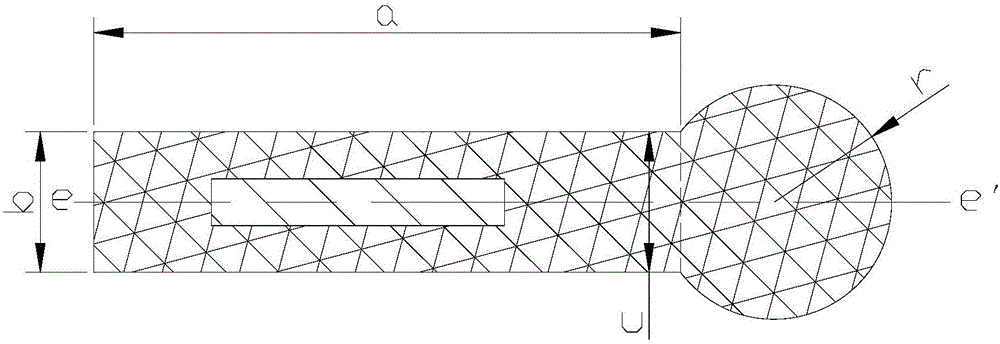

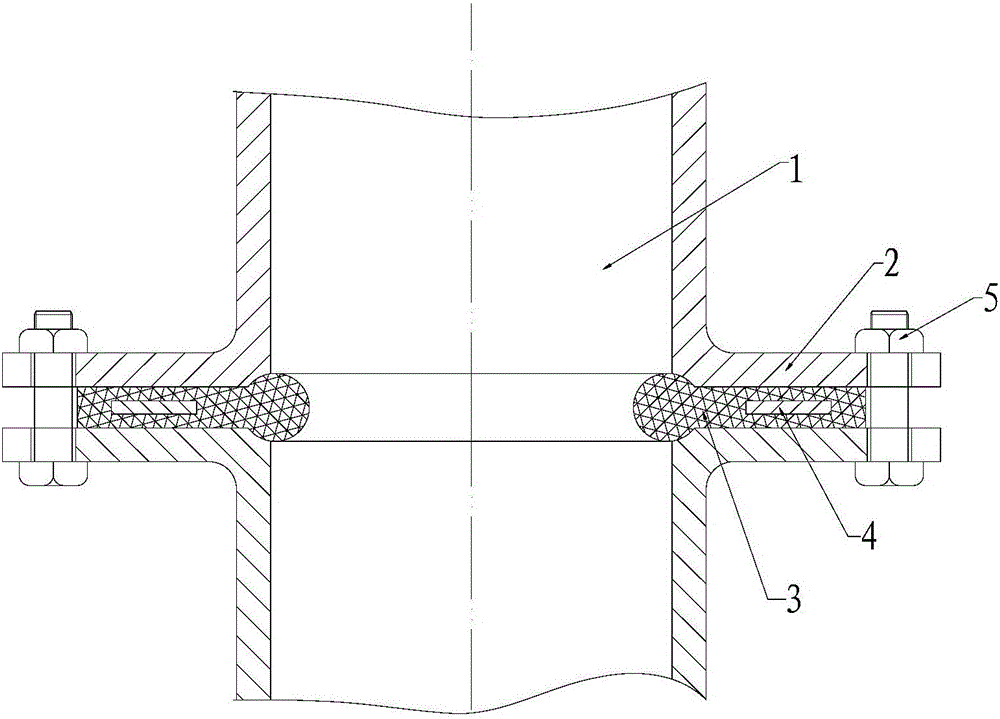

[0013] The present invention is a novel flange sealing gasket, which is characterized in that: the cross-sectional shape of the flange sealing gasket is a combination structure of a rectangular outer circle part and an O-shaped inner circle part. Wherein, the size of the section includes the length a and the width b of the rectangle, the radius of the O shape is r, and 2r≥b. It can be seen from the above that the flange sealing gasket of the present invention is a combination of a flange ring and an O-ring, that is, a conjoined annular O-ring is designed at the inner ring of the flat rubber gasket, and this cross-sectional shape enhances the The sealing performance of the flange sealing gasket of the present invention.

[0014] As a preferred mode of the present invention, in the flange sealing gasket of the present invention: the chord length of the intersection of the O shape and the rectangle is c, and c=b. In this way, there will be no downward depression at the intersect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com