Online equipment health state self-detection method and system for tobacco processing equipment

A technology of processing equipment and health status, which is applied in the field of tobacco processing equipment status health self-inspection, which can solve the problems of lagging evaluation results, lack of quantitative analysis of equipment, coarse particle size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention is described in detail below in conjunction with accompanying drawing:

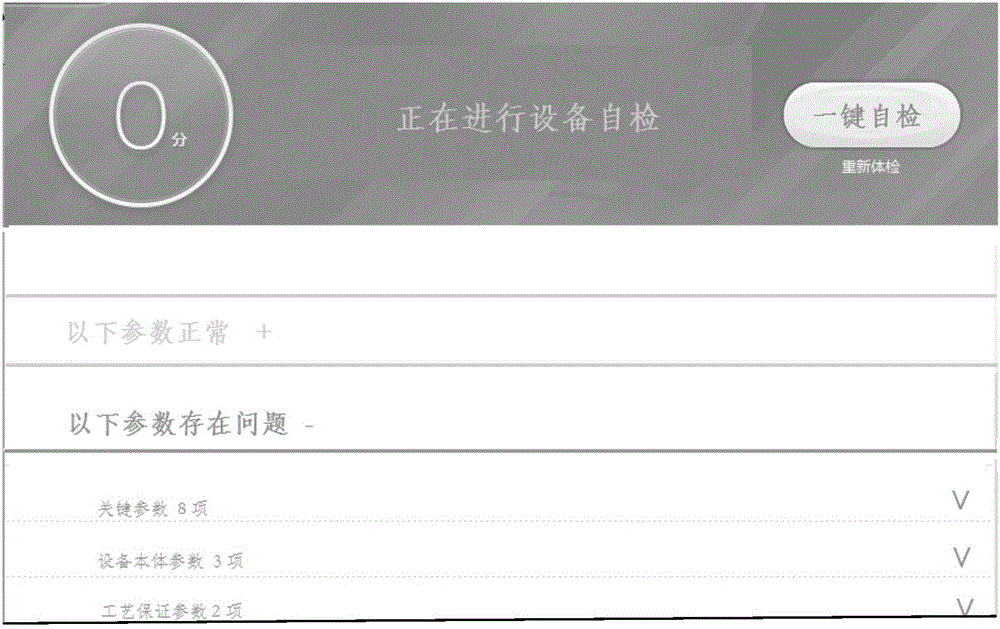

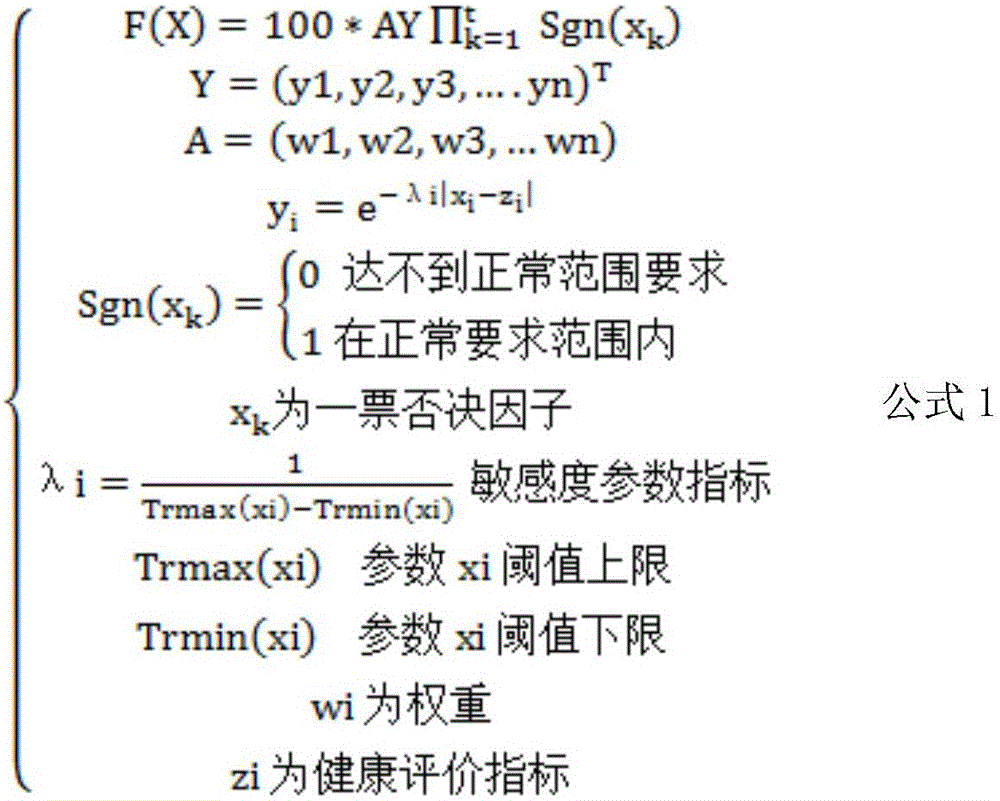

[0062] The present invention takes the tobacco blade feeding machine in the tobacco processing equipment as an example to specifically illustrate the online equipment health status self-inspection of the equipment, and the specific steps included are:

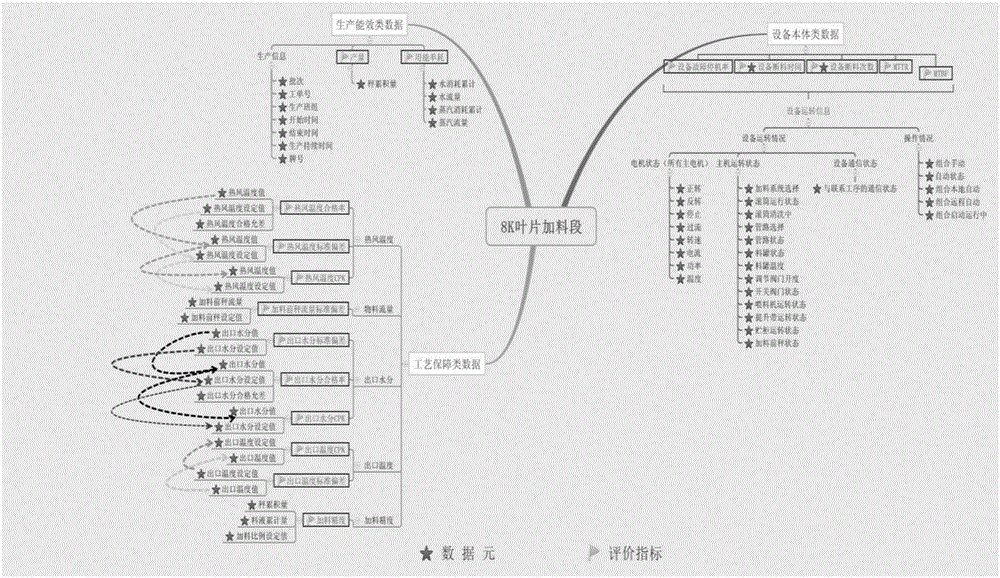

[0063] 1. According to the nature and purpose of the data owned by the equipment, the data can be roughly divided into three categories: equipment body data, process support data, and production energy efficiency data. The device body data mainly includes motor data, device operating parameters, device operation data, communication connection data, etc. The process assurance data covers various parameters related to the process. Production energy efficiency data mainly includes shift, batch, output and other related data. According to these three categories, the feeder data is organized by category and level. Form the feeder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com