A portable paddy field ditching machine

A trencher and portable technology, which can be used in excavation/covering trenches, planting methods, applications, etc., can solve the problems of high strength, high cost, and difficult operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

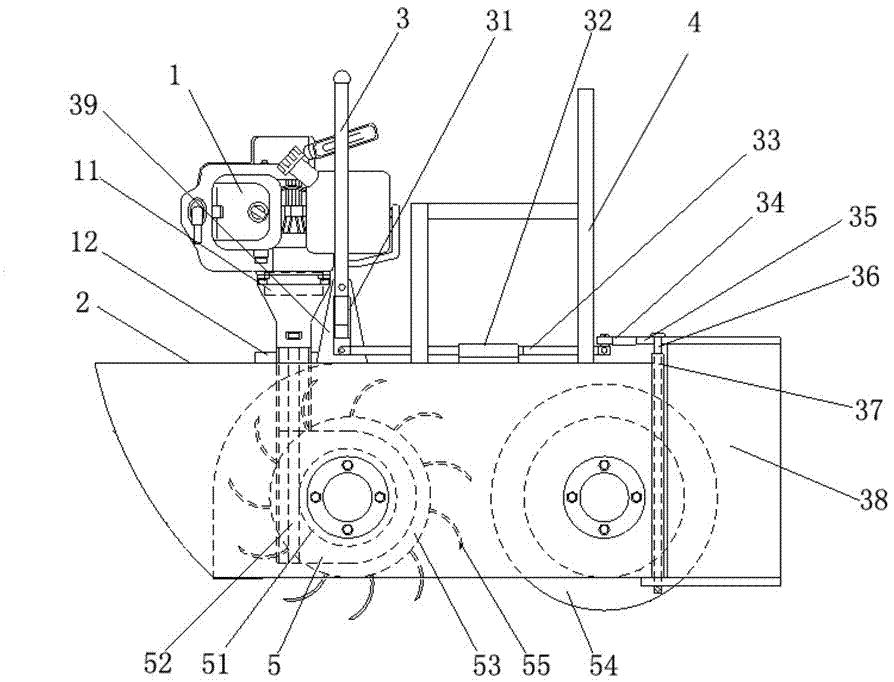

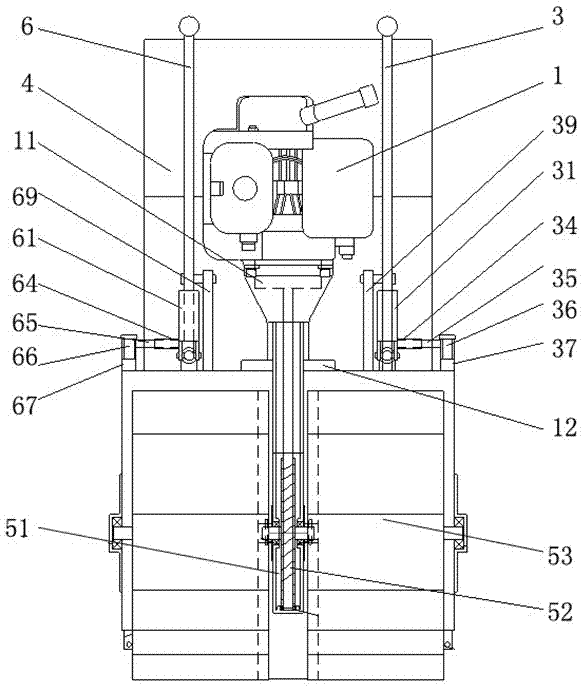

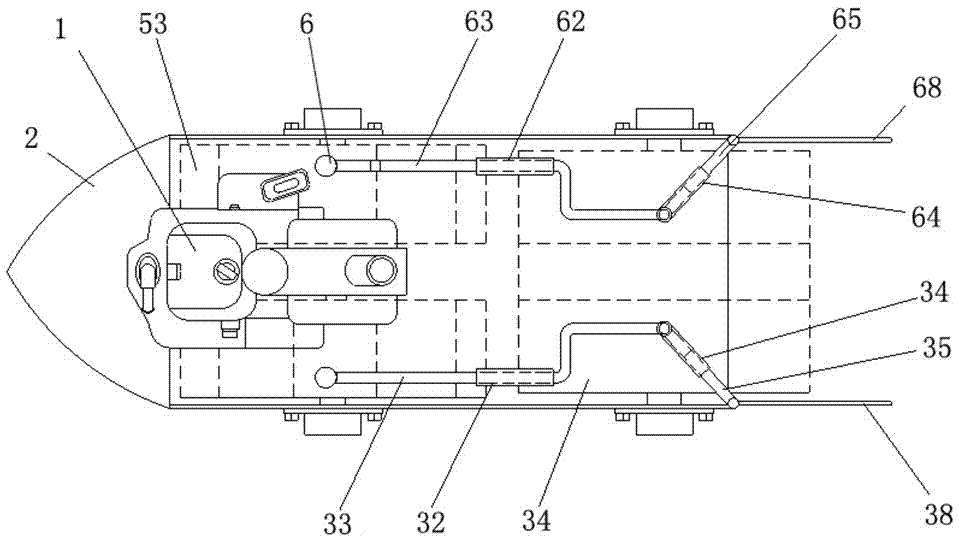

[0025] see figure 1 , a portable paddy field ditching machine, including a power assembly, a fuselage 2, a running mechanism, and a steering mechanism; the power assembly includes an engine 1, a speed change mechanism, and the engine 1 is an air-cooled gasoline engine with a power of 1.3W; see figure 2 The speed change mechanism is a speed change mechanism composed of a worm wheel 51 and a worm screw 52. The worm screw 52 is longitudinally arranged in the casing 5. The upper end of the worm screw 52 is provided with an external spline, and is connected with the internal spline of the clutch 11 provided on the engine 1. , the lower end of the worm 52 is a helical tooth; the worm wheel 51 is fixedly sleeved on the horizontal output shaft, and the worm wheel 51 meshes with the helical tooth at the lower end of the worm 52 to realize the rotation of the output shaft; the fuselage 2 is rectangular Box-shaped, the front end of the fuselage 2 is pointed, the engine 1 is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com