Greening biological brick

A bio-brick and brick-body technology, applied in the field of greening bio-bricks, can solve the problems of high cost, poor greening effect, high labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

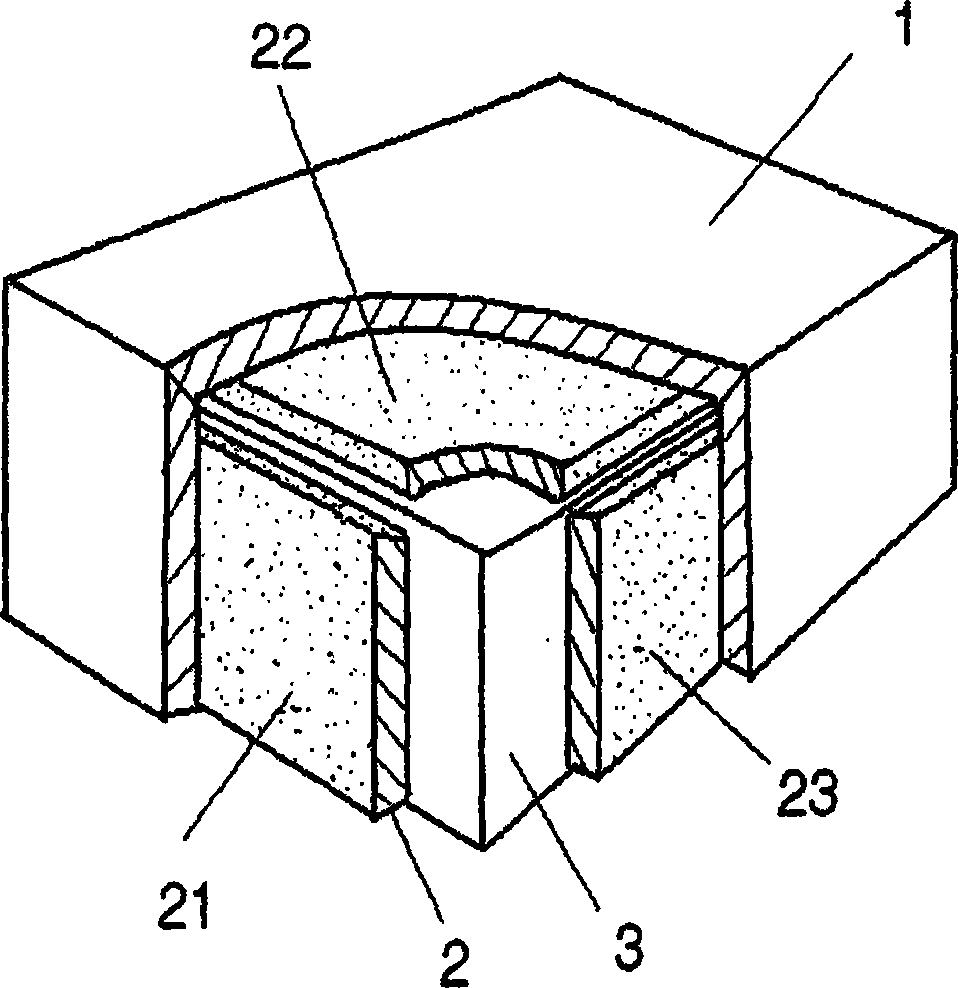

[0028] refer to figure 1 , a greening bio-brick, the brick body is composed of a matrix 1, a matrix 3 and a seed layer 2, and the seed layer 2 is arranged at a certain depth inside three adjacent outer surfaces of the brick body. 21, 22 and 23 respectively. Bricks of this shape are suitable as corner bricks for enclosures, allowing plants to grow on the three outer surfaces.

[0029] The brick is produced by factory mechanized brick-making method, with high-quality soil as the matrix, mixed with fertilizer and reinforcement components as auxiliary components (depending on the required degradation time, the reinforcement components can be nylon or strip-shaped flax fiber materials. For example: diameter 0.5mm, length 40-60mm), mix and stir evenly, first press the matrix material and the auxiliary component mixture to form the inner brick adobe 3, lay the seed layer on the three adjacent outer surfaces of the inner brick adobe, and then add it to the outside of the seed layer ...

Embodiment 2

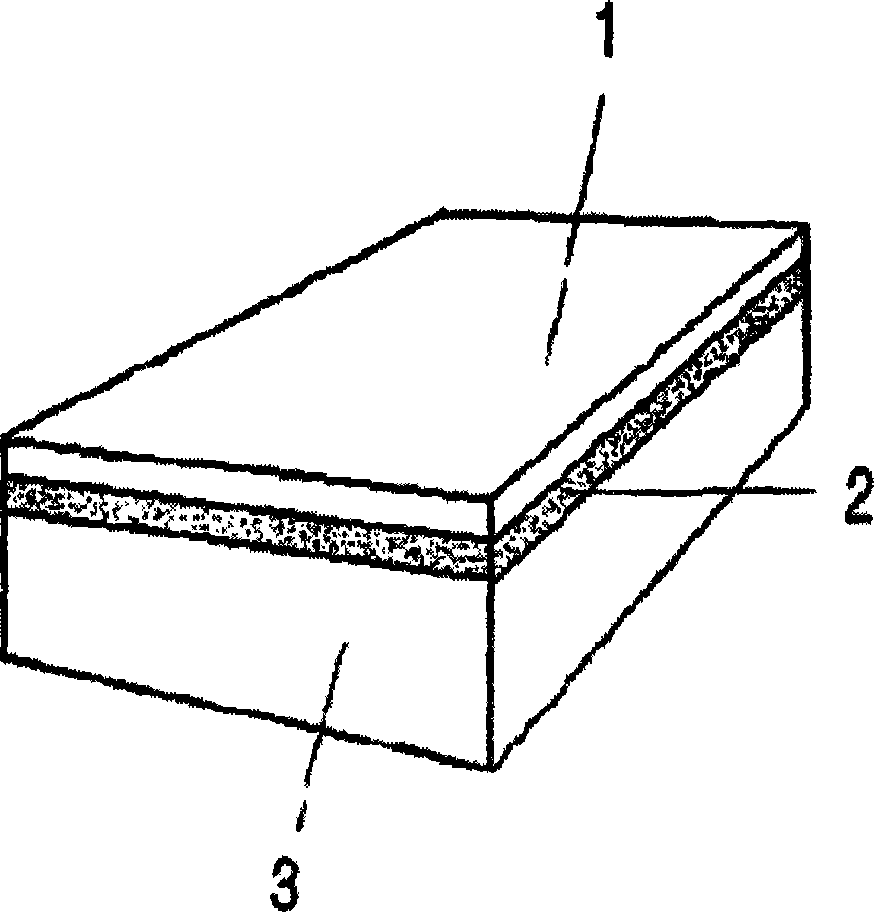

[0037] refer to figure 2 , a greening biological brick, the brick body is composed of a matrix 1, a matrix 3 and a seed layer 2, and the seed layer 2 is arranged at a certain depth inside an outer surface of the brick body. Bricks of this shape are suitable as a laying brick for flat laying, and plants can be grown on the upper surface. The laying method during use can be found in Figure 4 .

[0038] The brick is produced by factory mechanized brick-making method, with high-quality soil as the matrix material, firstly add the matrix of 70-90% of the brick body height into the mold, then evenly spread plant seeds on the matrix layer, and finally add the remaining matrix The material is capped on top of the seed layer and pressed into the final brick shape.

[0039] The brick body can be treated again with pesticides by injection or spraying. Finally, dry the bricks through a dryer (drying temperature should not destroy the physiological mechanism of the seeds, the general...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com